How to Invest in Manganese Stocks

Overview

Demand for the batteries necessary for clean energy technologies is expected to skyrocket in the coming decades, and analysts are already questioning if supply will be able to keep up. The problem is exacerbated by supply chain issues, with China controlling more than 50 percent of total market share in the processing of nearly all battery minerals, except nickel and copper.

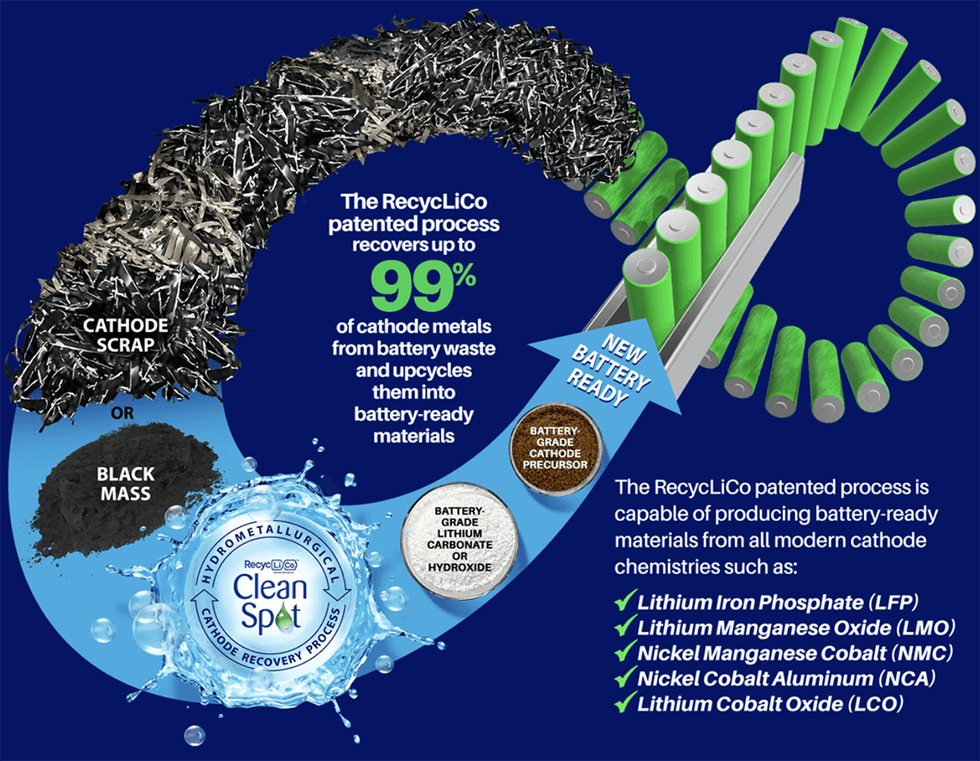

Miners and battery manufacturers are setting ambitious goals to keep up with demand, but there’s another option many overlook: recycling and upcycling. Analysts project lithium-ion battery capacity could reach 5,500 gigawatt-hours by 2030, up five-fold from 2021. Every watt-hour will eventually need recycling, whether right away or at the end of its life. Battery recycling is included in the US government’s National Blueprint for Lithium Batteries, as it strengthens the entire domestic supply chain. Innovative recycling technologies are emerging to feed end-of-life batteries and production waste back into the manufacturing process, creating new opportunities for investors to capitalize on the electrification revolution.

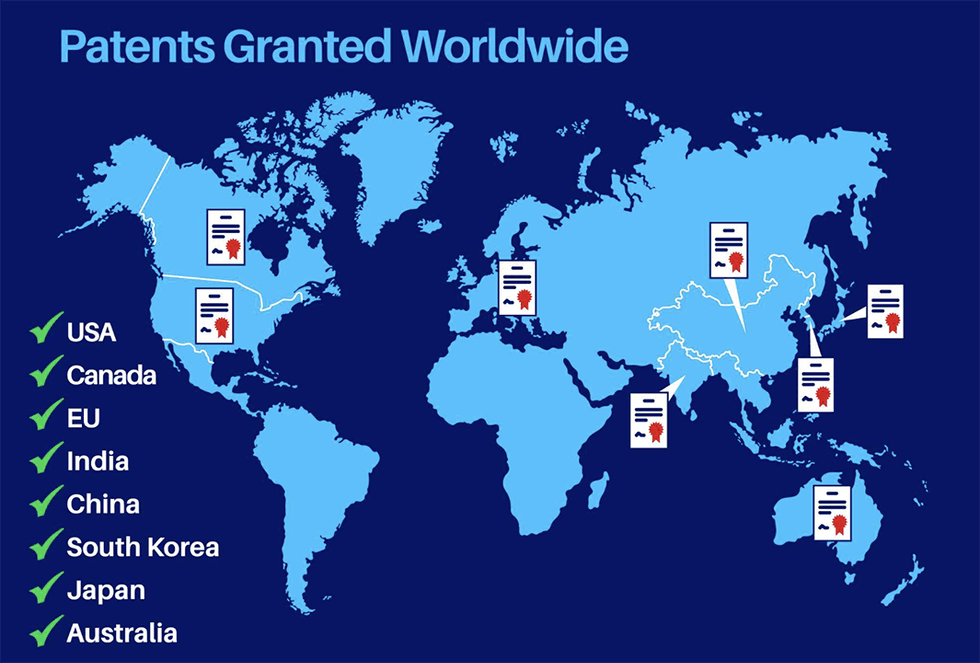

RecycLiCo Battery Materials (TSXV:AMY,OTC:AMYZF,FSE:2AM) is a critical metals company focusing on upcycling and recycling lithium-ion battery waste and end-of-life batteries into high-value, battery precursor cathode active materials (pCAM) and lithium chemicals. The company has invented a closed-loop RecycLiCo™ Patented Process to extract materials for direct integration into the re-manufacturing of new lithium-ion battery materials. RecycLiCo currently holds 13 granted patents from the United States, South Korea, Japan, China, India, Australia and Canada, with one anticipated patent approval from the European Patent Office, bringing the total to 14.

RecycLiCo’s pilot plant has already tested samples of black mass (shredded end-of-life batteries) and battery production scrap from multiple third parties and has proven the production of high-purity lithium and pCAM. The upcycled product was tested in new battery cells, which achieved equivalent performance characteristics of commercial materials from mined sources.

The lithium carbonate regenerated from recycled battery waste using RecycLiCo's patented process has successfully been qualified by C4V's Phase 1 Supply Chain Qualification program through testing in battery cells. New York-based C4V is a lithium-ion battery technology company that creates next-generation storage materials with expertise in Gigafactory solutions.

Through C4V's testing, RecycLiCo's lithium carbonate has been converted to cathode material and assembled into battery cells. The battery cell tests demonstrated good capacity and stability throughout cycle testing. These tests meet C4V's rigorous benchmarks and affirm the quality of RecycLiCo's recycled lithium rivals that of mined lithium, positioning RecycLiCo at the forefront of sustainable battery material production.

In 2024, RecycLiCo's lithium carbonate contained in a lithium iron phosphate (LFP) battery passed a comprehensive suite of tests conducted by a battery materials company in Asia. The results indicate the company's lithium carbonate has met, and surpassed the specifications required by the battery materials company, thus demonstrating the recycled product's battery-grade quality.

The conventional supply chain for battery metals is complex, requires significant global transportation, and is linearly dependent on new raw materials. RecycLiCo’s technology sidesteps this complex supply chain by processing battery production scrap and end-of-life batteries directly into high-value and specifically engineered materials that manufacturers require, closing the supply chain loop. The RecycLiCo™ Patented Process requires minimal processing steps and provides more than 99 percent extraction of lithium, cobalt, nickel and manganese.

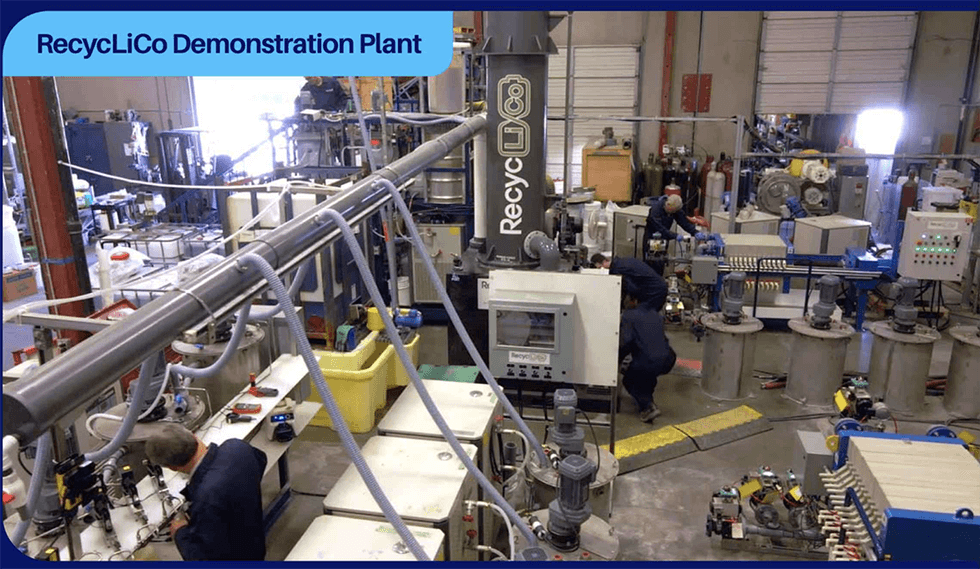

RecycLiCo’s demonstration plant is designed with a 500 kg/day processing capacity of waste battery materials, and is intended to test scaled-up operating conditions to achieve optimum process configuration and commercial plant design. Testing has resulted in the production of bulk quantities of battery-grade lithium carbonate from an industrial feed of cathode scrap. The company achieved 163 percent of the designed processing capacity for lithium-ion battery cathode scrap. The leach section of its technology also achieved more than 99 percent extraction of lithium, nickel, cobalt and manganese from lithium-ion battery production scrap.

RecycLiCo has delivered samples of its battery-grade lithium carbonate and lithium hydroxide to battery manufacturers in Japan and South Korea for a technical review and to explore potential business partnership opportunities.

The company entered a 50-50 joint venture with Zenith Chemical Corporation to build a 2,000-metric-ton-per-year lithium-ion battery recycling plant in Taiwan. Estimated to cost US$25 million, the initial plant will be dedicated to processing and converting lithium-ion battery waste into valuable resources such as pCAM, lithium hydroxide monohydrate and lithium carbonate.

RecycLiCo continues to pursue joint ventures with strategic partners that can co-locate the recycling technology alongside the manufacturer’s facility, eliminating the need for additional transportation.

RecycLiCo’s recycling technology has undergone a life cycle assessment conducted in accordance with ISO standards and was critically reviewed by independent experts. The results indicate a dramatic reduction in global warming potential, demonstrating a 62 percent reduction over competing hydrometallurgical battery recycling methods.

RecycLiCo and Nanoramic Laboratories recently disclosed successful results from their lithium-ion battery cathode recycling collaboration. Laboratory test results have demonstrated that RecycLiCo’s recycling process can efficiently treat Nanoramic's innovative NMP-free and PVDF-free electrodes without concern. Nanoramic’s and RecycLiCo’s collaboration was facilitated through the US Department of Energy’s Advanced Energy Manufacturing and Recycling Grant Program.

RecycLiCo is led by a strong management team and advisory board with extensive experience in the natural resources industry, process development projects and international finance. The impressive roster of leaders and advisors creates additional confidence in the company’s ability to fully develop and commercialize its transformative technology.