Torch River Resources: Pursuing Lump Graphite in Quebec and Sri Lanka

Graphite Investing News spoke with Paul Ogilvie, CEO of Torch River Resources, about his team’s background, the company’s property acquisition plans and how lump graphite is priced.

Last month, Graphite Investing News (GIN) had the opportunity to sit down with Paul Ogilvie, CEO of Torch River Resources (TSXV:TCR), a Canadian company whose goal is to become a pure-play lump graphite miner.

In the interview below, Ogilvie discusses his team’s background, the company’s property acquisition plans and how lump graphite is priced.

GIN: To start off, could you tell me about your team’s background?

PO: Our team came together around seven years ago, well ahead of the curve in terms of identifying the graphite sector as the place to be. That process began with a company called Industrial Minerals. It’s now called Northern Graphite (TSXV:NGC). A number of folks before us had tried to get the graphite property it held off the ground; however, our team created the first real financial models, engineering design and NI 43-101 resource report on the project. All of that was ultimately the framework required to finally put the project on the right track.

From there, we moved on to build Mega Graphite, which was focused on a large-flake graphite project in Southern Australia. It was and remains a good project aside from ownership issues that have delayed its development for the time being. We then worked in 2012 on expanding Bolero Resources into a more focused graphite company. In the process, we changed its name to Canada Carbon (TSXV:CCB) to better reflect its acquired graphite properties in Quebec. As that work proceeded, it became clear to us that pursuing a lump graphite business model made enormous sense. So we’re now working on two of our four lump projects: those in Quebec, and of course the larger project in Sri Lanka. We believe both have the potential to be game changers when it comes to any other graphite project in the world. For anyone to actually do this on a commercial level, instead of just on a one-vein-at-a-time level, is pretty significant.

While mining guys are well represented on our team, we have an equally strong group that comes from the engineering, sales and marketing worlds. This is critical because the graphite business is driven primarily by sales, marketing and R&D. On that basis, I feel our team is very experienced, certainly in North America and in other places around the world. Collectively we understand graphite mining, processing and purifying, all of which leads to developing innovative products, including making the right chemistry ready for lithium-ion batteries.

GIN: Could you give a bit more of a rundown on Torch River? From your website I see that the company is currently undergoing a transformation.

PO: That’s correct. Torch River — which hopefully soon will be named Saint Jean Carbon — is a public company that was turned over to our team to build out. Originally it was in the moly and gold business with related properties. I took on the project of transforming the company because the board really wanted to be in the graphite business. I was very conscious of the quality of some of the lump properties that were going to become available, so it was a nice fit for both my team and the board of Torch.

GIN: What will happen to your non-graphite properties as the company makes this shift?

PO: As I noted, our focus now is the graphite business. We have people calling all the time to discuss our other assets. We believe they’re good assets for the right company; I would imagine that in the next year or two we’ll find good homes for these properties.

GIN: In July, you announced that you’re working towards a merger that will put you in a better position to develop Sri Lankan lump graphite deposits. How is that progressing?

PO: We are working through all the terms — it’s fantastic. I’m limited in what I can say, except I will tell you that it’s roaring right along. We’ve been working closely with our partners in the project for more than two months and I believe the probability of us closing is extremely positive. They know our team and that was instrumental in us being able to come together. There were some bigger contenders competing with us, but I believe we won because at the end of the day we demonstrated that we understand the business, we bring a complete and experienced team, we know how to manage a project and we could arrive at a deal that works for everyone. We’re very proud of that.

GIN: What about the Walker property in Quebec? Has your acquisition been finalized?

PO: We have closed the transaction to acquire the past-producing Walker lump graphite mine. As you are aware from our previous release, our composite grab sample yielded grades as high as 89.5-percent Cg in the first sampling program. Subsequent work on the Walker property is immediately planned and will comprise a more complete sampling program and structural analysis of the exposed vein system. We also are moving forward to close Wallingford and Saint Jovite, also past-producing lump mines.

GIN: What makes Torch River stand out from its competitors?

PO: As I’ve noted, we have a realistic understanding of the dynamics of the graphite business. For example, it might seem obvious, but high grades generally mean lower operating costs and better margins. Over the past few years there has been a rush to develop a lot of graphite properties, and I think some of those economic realities have been overlooked. I think we also have an excellent handle on what those costs can and should look like. So whenever we assess a project, we come at it trying to make sure the project works on all levels – and that includes being able to effectively satisfy the varied requirements of graphite customers. That was a principle factor in pursuing the Sri Lankan project. There you can get graphite out of the ground and on a truck for roughly $100 a ton. There’s a profound difference between that and, let’s say, Ontario projects with a cost base upwards of $1,300 to $1,400 a ton. Quebec projects with their higher grades are looking at $800 to $1,000 a ton. So a cost difference such as that between Torch and these projects will represent a distinct competitive advantage for us. Keep in mind, I’m not including our Quebec projects in that statement as our projects are lump.

The other significant thing is that a lot of our material comes out of the ground at extremely high purity, in the 95-percent-plus Cg range. That means you actually have material that you can sell at between $2,000 and $3,000 a ton without extensive upgrading. Even the high-quality material of Ontario-type projects still has to be upgraded to get into those numbers because the grade is so low. That can be another $1,000 in upgrading costs over and above the $1,400. So from a profitability standpoint, you can’t compete with our material. Synthetic can’t compete with it and no other graphite miner can compete with it.

Those grades also dramatically reduce our anticipated capital expenditures to build the facilities necessary to mine and process our material. Our current budget planning is projecting costs of $10 to $12 million to become fully operational. Compare that to a typical Ontario or Quebec large-flake project, which is looking at $140 to $150 million, and you can quickly begin to see the impact on overall profitability and return on investment. Ultimately, when we look forward six or seven months from now, we see ourselves as the largest holder of lump graphite in the world and plan to be in production before anybody else.

GIN: Could you go over how lump graphite is priced in comparison to other types of graphite?

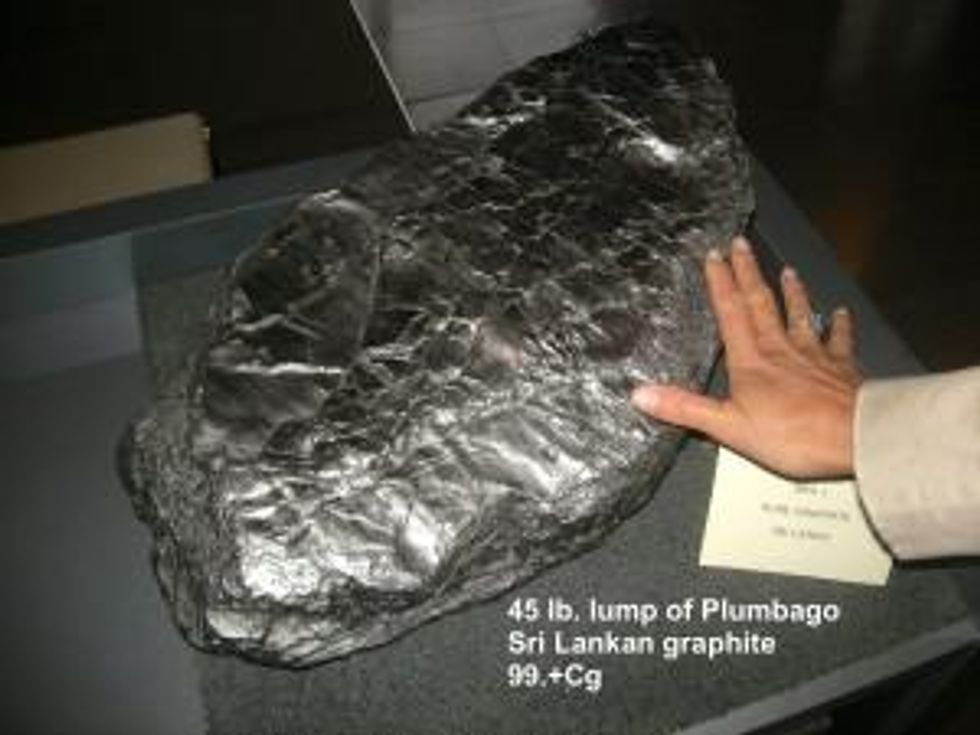

PO: I think it’s important to note that all graphite has a crystalline structure, whether it’s large, medium or small flake, amorphous or lump. Flake and lump are similar in that they both have highly ordered crystalline structures, whereas amorphous has a more irregular structure. The ordered structure of flake and lump make them ideal for a wide range of applications, while amorphous has a more limited range. The principal difference between flake and lump, of course, is the grade. Flake grades typically range from 2 to 10 percent, while lump such as that found in Sri Lanka can easily be in excess of 80 percent. Amorphous grades are generally in between 15 and 30 percent.

These grades are also a reflection of purity. With lump being roughly a solid mass, the level of impurities is very low. In some cases, a low grade can be offset somewhat by the fact that the graphite is a good-quality material. Each of these factors influences price. Flake and lump graphite that is processed to 98-plus-percent purity with mesh sizes of +35 to 80 should be able to achieve prices between $1,800 to $2,500 per ton. Amorphous, with its different structure, sells for $800 or $1,200 a ton. The great thing about our lump graphite is the low cost per ton. This gives us significant latitude when it comes to being price competitive for customers. This will also give us broad access to a wide range of global markets while allowing us to operate profitably.

GIN: Is there anything else you want to add?

PO: I think we’re building the most successful company coming down the pipe right now. I truly believe that the more the world gets to know us the more we will be clearly recognized as the number-one upcoming graphite company. My team has been doing this long enough that I think most other graphite companies will have a tough time competing with us, whether it’s from a pricing, quality or execution standpoint. Keep a close eye on us, because we’re building the real deal.

GIN: Thank you for speaking with me.

Securities Disclosure: I, Charlotte McLeod, hold no direct investment interest in any company mentioned in this article.

Editorial Disclaimer: Interviews conducted by the Investing News Network are edited for clarity. The Investing News Network does not guarantee the accuracy or thoroughness of the information reported. The opinions expressed in these interviews do not reflect the opinions of INN and do not constitute investment advice. All readers are encouraged to perform their own due diligence.

Related reading: