Investor Insight

International Graphite’s is building a global mine-to-market graphite supply chain with a network of downstream processing operations in allied markets, underpinned by a world class resource in Australia. This will deliver a secure, reliable supply of high-value graphite products for growing industrial and battery markets across the US, Europe and Asia.

Overview

International Graphite (ASX:IG6 ,FRA:H99) offers low risk, near-term entry to the growing graphite market. Shifting from developer to producer, International Graphite’s first commercial processing facility is now under construction in Collie, Western Australia. The company’s ISO-certified R&D and qualification operations have already shipped product samples and recorded initial sales, helping to seed customer relationships ahead of ramp-up. The strategy is deliberately modular: start with value-added industrial products that can generate early cash flow, then scale capacity and product mix to high value battery materials, as demand and capability build. To date, the company’s Western Australian projects have received AU$17.2 million in grants from Australian state and federal governments.

In parallel, a 50/50 joint venture is advancing in Germany to establish an expandable graphite plant, placing International Graphite inside the EU’s industrial heartland and adding a second revenue stream in applications such as flame-retardant plastics and thermal management.

Together with Collie, the two processing facilities have the potential to add approximately 10,000 tonnes per annum (tpa) of graphite products from 2027. Europe is currently one of the world’s biggest consumers of expanded graphite, almost all of which is imported.

Longer term, growth is anchored by the 100-percent-owned Springdale graphite project in Western Australia, providing security of supply for the vertically integrated process network and supporting plans to move further downstream into battery anode materials. The development pathway is supported by government backing and strategic partners, with additional funding avenues being progressed. All of this is pursued in tier-one jurisdictions with a focus on quality, certification and responsible development – attributes increasingly demanded by global customers.

Company Highlights

- Near-term revenue: Construction is underway at Collie, WA for Australia’s first commercial graphite micronising plant – designed to generate early cash flow with a straightforward path to expand capacity.

- European expansion: A 50/50 joint venture is progressing to build an expandable graphite facility in Germany, putting International Graphite inside the EU market for flame-retardant and thermal products and broadening revenue beyond batteries.

- De-risked funding: Collie has strong grant funding support from Australian national and state governments. The European project has a financing partner with a mandate to arrange significant non-dilutive funding.

- Customer traction: ISO-certified operations in Collie are supplying qualification products to potential domestic and international customers and have recorded initial sales ahead of commercial scale-up.

- Resource-backed growth: The Springdale graphite resource and future mine (mining leases granted) underpins long-term feed supply for downstream operations with proven quality and metallurgical characteristics that are optimal for battery anode materials.

- Scale ambition: The two process facilities at Collie and in Germany have potential to deliver >10,000 tpa of high-value graphite products with production targeted to start in 2027.

Key Projects

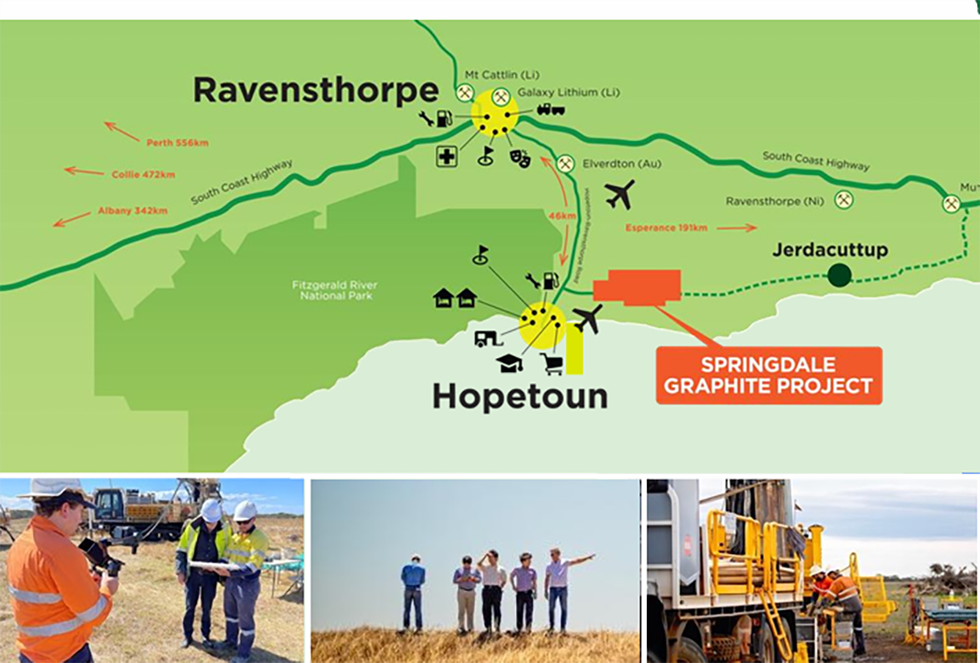

Springdale Graphite Project

Springdale is a large, fine-flake resource in Western Australia that underpins International Graphite’s mine-to-market plan. The current mineral resource is 49.3 Mt @ 6.5 percent total graphitic carbon. With only a small portion of the tenements drilled to date, there is significant room for resource growth. The January 2024 scoping study outlines a long-life, open pit mine producing ~46,000 tpa of concentrate for AU$76 million capex. Bench-scale testwork on Springdale concentrates has achieved battery-grade purities (>99.95 percent to 99.99 percent), with spheroidising yields up to 76 percent and near-theoretical electrochemistry (372 mAh/g). Springdale also benefits from a non-binding MoU with Marubeni, a supportive local community and established resource industry infrastructure. Two mining leases have been granted that cover most of the tenement area.

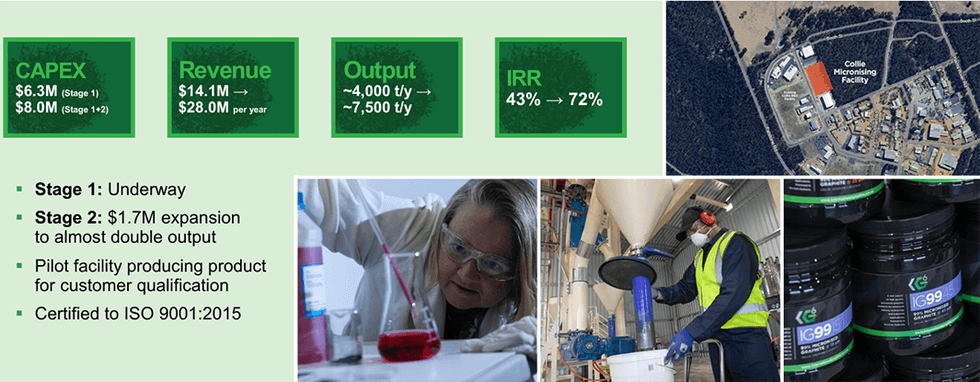

Collie R&D and Processing Facility (Western Australia)

International Graphite is developing Australia’s first commercial graphite micronising plant at Collie, in Western Australia. The March 2025 front-end engineering design study estimates Stage 1 at ~4,000 tpa for AU$6.3 million, with an additional AU$1.7 million to lift capacity to ~7,500 tpa. Detailed design is underway and a supply contract and purchase orders have been issued for the micronising process equipment. Collie’s ISO-certified R&D/qualification facility remains active having processed 1,216 kg of concentrates into micronised and spheroidised products with initial sales achieved. Company presentation metrics indicate revenue potential of ~AU$14.1 million to ~A$28 million per year at Stage 1/Stage 2, with indicative IRRs of 43 percent to 72 percent (subject to funding and final approvals).

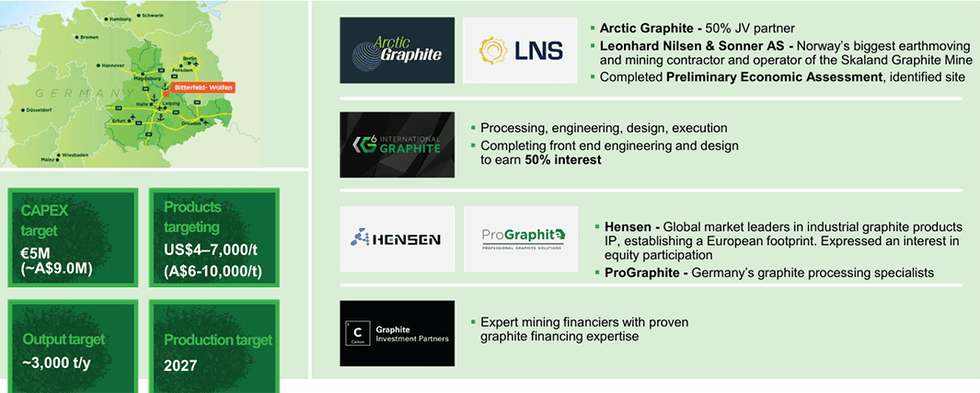

European Expandable Graphite Facility (Germany)

International Graphite has signed a co-operation agreement with Arctic Graphite AS to form a 50/50 joint venture to develop an expandable graphite facility in Europe, with Germany as the preferred site. The facility targets ~3,000 tpa of product for a €5.0 million capital cost. Graphite Investment Partners (GIP) will arrange ≥50 percent non-dilutive funding and has issued a non-binding LOI to arrange up to AU$10 million for the German facility and Collie (subject to due diligence and terms). The assessment scope targets efficient, scalable development using third-party feedstock, with technical partners ProGraphite and Hensen supporting engineering and product development. Arctic’s shareholder LNS brings long-standing European graphite operating experience.

Successful delivery of the German plant alongside Collie would position International Graphite to produce ~10,000 tpa of high-value graphite products from 2027.

Management Team

Phil Hearse - Chairman

One of Australia’s leading metallurgists and an authority on graphite project development, Phil Hearse founded International Graphite in 2018 and continues to lead the company’s growth and development. An engineer with more than 40 years of experience in diverse and challenging projects around the world, his extensive career has taken him from operational and technical roles at Broken Hill, Bougainville Copper, Queensland Nickel (QNI) and Gove Alumina to senior executive and managerial positions in engineering and operating companies.

Hearse is the owner and managing director of Battery Limits, one of Australia’s leading graphite metallurgy and process engineering firms. The company has assisted many listed public companies to develop bankable feasibility studies for graphite mines and concentrators and has generated significant intellectual property in downstream processing and knowledge of the end use market. Hearse has an MBA from Hull University UK and a Bachelor of Applied Science in primary metallurgy from the University of SA. He is a fellow of the Australasian Institute of Mining and Metallurgy and a fellow of the Australasian Institute of Mining and Metallurgy.

Andrew Worland - Managing Director and Chief Executive Officer

Andrew Worland is a mining executive and experienced ASX/TSX director with over 25 years in senior finance, corporate, project management and marketing roles in the Western Australian mining sector.

Worland's commodity experience includes exploration, development and operations in lead, zinc, nickel, cobalt, gold, iron ore, molybdenum, copper and uranium. He has a Bachelor of Commerce with a major in finance and marketing from the University of Western Australia and is a qualified chartered company secretary and has achieved Fellow of the Governance Institute of Australia.

David Pass - Non-executive Director and Technical Director

David Pass has played a key role in the technical development of International Graphite since the company’s inception. A metallurgist with 30 years in the mining industry, he brings a mix of operational processing, process design, project, due diligence skills and management experience including mine operations experience with Barrick Gold.

Pass is chief executive officer of Battery Limits and an acknowledged expert in graphite primary and downstream processing and has led several studies in graphite project development to definitive feasibility level. He holds a Bachelor of Science in metallurgy from Murdoch University and is a member of the Australian Institute of Mining and Metallurgy.