Pilot Plant Engineering Underway at Kachi Lithium Project

Lilac Solutions Direct Extraction Plant On-Track to be Operational at Kachi Project Late 2019 Targeting Rapid, Low-Cost Lithium Production With High Recoveries And Minimal Environmental Impact

Lilac Solutions Direct Extraction Plant On-Track to be Operational at Kachi Project Late 2019 Targeting Rapid, Low-Cost Lithium Production With High Recoveries And Minimal Environmental Impact

- First steps towards pilot plant testing with design and engineering underway at Lake’s Kachi Lithium Project, Argentina based on high-productivity, high-purity Lilac Solutions direct extraction technology.

- Design and engineering phase expected to take three months. This will then lead to an estimated 3 months of construction, with delivery of the pilot plant on-site at Kachi and commissioning expected in late 2019.

- Pilot plant forms part of pre-feasibility study (PFS), as a precursor to full-scale commercial project offering rapid, low-cost production with minimal environmental impact.

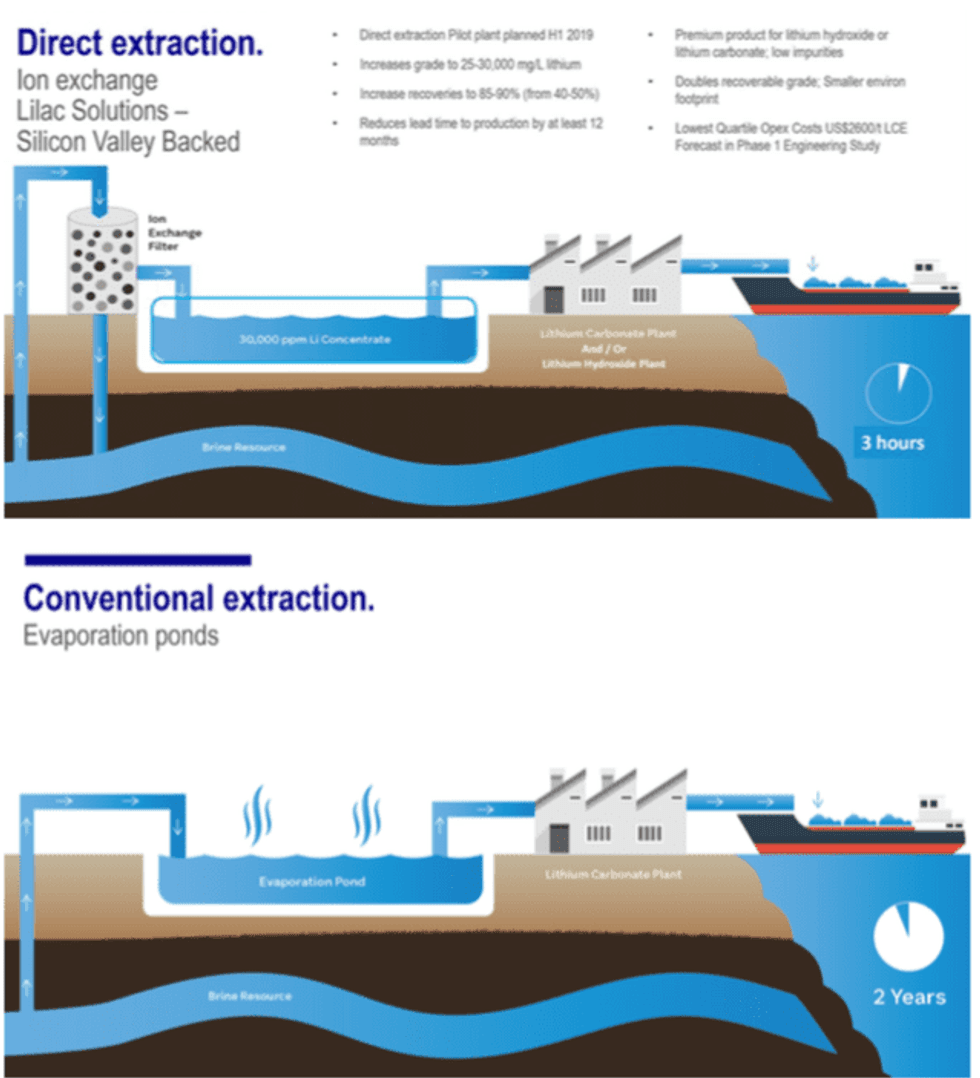

- Phase 1 Engineering Study showed potential for production costs to be in the lowest quartile of global lithium production costs; high lithium concentrations of 30,000 mg/L produced after 3 hours of processing from ~300 mg/L brines, with recoveries of 85-90% confirmed from multiple samples.

Lithium exploration and project development company Lake Resources NL (ASX: LKE) announced today the commencement of design and engineering works for the Company’s planned pilot plant at its 100% owned Kachi Lithium Brine Project in Argentina. Based on U.S. partner Lilac Solutions’ direct extraction production technology, the pilot plant will test the potential for rapid, low-cost production with high recoveries and minimal environmental impact, at a pilot scale, offering a significant competitive advantage.

This follows December’s release of a successful Phase 1 Engineering Study conducted by the Silicon Valley- backed Lilac Solutions, with the study showing its direct extraction process has the potential to rapidly produce very high lithium concentrations from Kachi brines with low impurities (refer ASX announcement 10 December 2018).

Lithium concentrates of 30,000 mg/L have been produced using the Lilac technology in just three hours from Kachi brines, with trials up to 50,000 parts per million (ppm), together with evaporative dewatering. Significantly, high lithium recoveries of 85-90% were obtained compared to the typical 40-50% recoveries using conventional evaporation processes, maximising the resource.

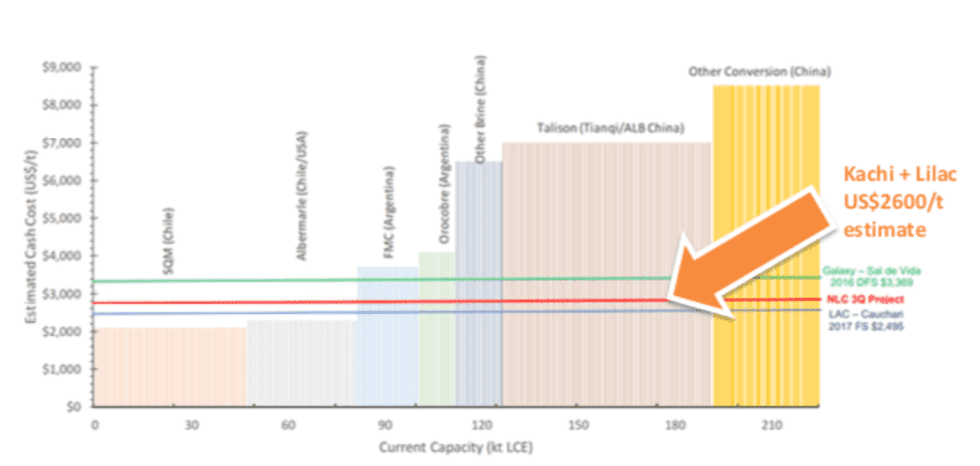

Importantly, the study showed globally competitive production costs of US$2,600/tonne (+/-30%), which is in the lowest cost quartile for lithium carbonate production, using a commercial-sized Lilac Solutions production plant. (Note: The estimated costs of production are preliminary estimates based on the Phase 1 Engineering study.) The lithium concentrate stream could then be processed downstream into battery-grade lithium product using conventional purification technologies (either a conventional lithium carbonate plant or hydroxide plant).

This compares favourably with conventional brine operations in South America, which use evaporation that requires a lengthy 9 to 24 month waiting period for the process to produce a suitable lithium brine concentrate for processing, and have lithium recoveries typically below 50%.

Lilac’s extraction technology also offers the potential for reduced environmental impact compared to traditional processes used in Argentina, due to the removal of evaporation ponds. In addition, the remaining brine would be reinjected into the aquifer from which it is sourced without significantly affecting the water quality, thereby preserving an aqueous resource in an arid environment.

Lilac’s Chief Executive Officer, David Snydacker said: “We are confident that combining Lilac’s high- performance, next-generation lithium extraction technology with the massive lithium resource at Kachi will result in the most modern, efficient, reliable, and environmentally friendly lithium project in the world.”

Lake’s Managing Director, Steve Promnitz said: “The commencement of the pilot plant process is a milestone event, not only for Lake but also for the lithium industry more broadly, as we work to unlock the benefits of direct extraction technology. By combining cutting-edge Silicon Valley innovation with established mining industry know-how, there is potential for the creation of a sustainable competitive advantage in an industry that is at the centre of a global revolution in energy and transport.”

The PFS process for Kachi has already commenced (refer ASX announcement 9 April 2019), under which a leading international engineering firm has been engaged to examine its technical and economic viability, including both conventional and direct extraction methods, project engineering design, product specifications, optimisation of recovery and operating and capital costs.

Lilac has commenced the detailed design and engineering phase of the pilot plant, together with an international engineering firm, which is expected to take approximately three months. This will be followed by the build and transport of the plant to site at Kachi, where it will be installed and commissioned.

The pilot plant is expected to be capable of producing around 10 tonnes per annum of lithium carbonate equivalents. The planned approach is to produce a concentrate of purified lithium brine on-site and then convert it to lithium carbonate and/or lithium hydroxide at a location with more established infrastructure and workforce. Most reagents can be easily sourced locally, and Lilac will provide its proprietary ion exchange media. Based on the current timeline, the plant could be operating in late 2019, expected to be a precursor to a full-scale commercial project.

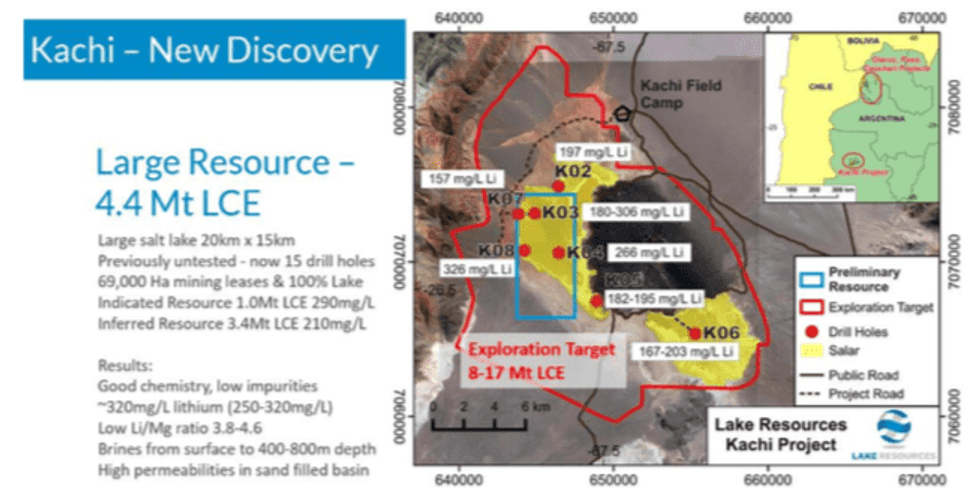

The Kachi project has an Indicated and Inferred Resource of 4.4 Mt LCE (Indicated 1.0Mt and Inferred 3.4Mt) within a much larger Exploration Target (refer ASX release 27 November 2018), covering some 69,000 hectares over almost an entire lithium-bearing salt lake in Catamarca Province.

Based on market feedback, Lake considers there is potential for Lilac’s technological solution to attract support from Silicon Valley-based and/or downstream investors, given Lilac’s investor base and the recent U.S. drive to develop its lithium industry. New U.S. legislation aims to speed the development of lithium and other electric vehicle (EV) supply chain minerals, facilitating increased EV output in the United States.

Demand forecasts point to the need for an eight-fold rise in lithium supply over the next nine years, on the back of the EV revolution, battery storage and other applications. With supply from major producers continuing to fall short of projections, new projects and technologies will be essential to support the industry’s growth.

Recent merger and acquisition (M&A) activity, both at the corporate level and in projects adjacent to Lake’s in Argentina, also points to a bright outlook for the sector as investors re-evaluate its potential.

Lake’s Mr Promnitz added: “Lake’s Argentina projects are in the heart of the Lithium Triangle, home to half the world’s lithium output and at the lowest cost.

“With our Kachi project now gaining momentum with the benefit of an innovative technological process and drilling underway at the Cauchari project (refer ASX announcement 1 May 2019), Lake is entering a significant new phase of its evolution as we work to deliver wealth for shareholders and benefits for all industry stakeholders.”

Figure 1. Conventional process for lithium extraction of brines from evaporation ponds (left) versus Lilac’s innovative Ion Exchange method (right), which promises high recoveries in a few hours versus 9-24 months using the traditional method of evaporation to concentrate the lithium. Lilac’s method allows for the reinjection of brines into the aquifer from where it is sourced, without significantly adjusting the water quality.

Figure 2. Global Lithium Cost Curve Estimate – Kachi Lithium Project using Lilac method would place operating costs in lowest quartile. Graph showing SQM and ALB from the Salar de Atacama does not include CORFO royalty structure increasing costs to ~US$6,000-10,000/tonne. Source: Roskill, Global Lithium LLC, Neo-Lithium Corp.

For further information please contact:

Steve Promnitz

Managing Director

+61 2 9188 7864 steve@lakeresources.com.au

Released through: Ben Jarvis, Six Degrees Investor Relations: +61 (0) 413 150 448

Figure 3. Kachi Lithium Project showing drilling locations, average lithium concentrations for each drill hole, the Exploration Target and the area of the Indicated Resource.

About Lake Resources NL (ASX:LKE)

Lake Resources NL (ASX:LKE, Lake) is a lithium exploration and development company focused on developing its three lithium brine projects and hard rock project in Argentina, all owned 100%. The leases are in a prime location among the lithium sector’s largest players within the Lithium Triangle, where half of the world’s lithium is produced. Lake holds one of the largest lithium tenement packages in Argentina (~200,000Ha) secured in 2016 prior to a significant ‘rush’ by major companies. The large holdings provide the potential to provide consistent security of supply demanded by battery makers and electric vehicle manufacturers.

The Kachi project covers 69,000 ha over a salt lake south of FMC’s lithium operation and near Albemarle’s Antofalla project in Catamarca Province. Drilling at Kachi has confirmed a large lithium brine bearing basin over 20km long, 15km wide and 400m to 800m deep. Drilling over Kachi (currently 16 drill holes, 3100m) has produced a maiden indicated and inferred resource of 4.4 Mt LCE (Indicated 1.0Mt and Inferred 3.4Mt) within a 8-17 Mt LCE exploration target grading in the range of 310 mg/L to 210 mg/L lithium 1(refer ASX announcement 27 November 2018).

A direct extraction technique is being tested in partnership with Lilac Solutions, which has shown 80-90% recoveries and lithium brine concentrations in excess of 25000 mg/L lithium. Phase 1 Engineering Study results have shown operating costs forecast at US$2600/t LCE in the lowest cost quartile 2. This process is planned to be trialled on site in tandem with conventional methods as part of a PFS to follow the resource statement. Scope exists to unlock considerable value through partnerships and corporate deals in the near term.

The Olaroz-Cauchari and Paso brine projects are located adjacent to major world class brine projects either in production or being developed in the highly prospective Jujuy Province. The Olaroz-Cauchari project is located in the same basin as Orocobre’s Olaroz lithium production and adjoins Ganfeng Lithium/Lithium Americas Cauchari project, with high grade lithium (600 mg/L) with high flow rates drilled immediately across the lease boundary.

An additional new rig has been deployed to increase the depth capacity and speed of the drill rig currently at Cauchari. Results are expected to extend the proven resources in adjoining properties into LKE’s area. This will be followed by drilling extensions to the Olaroz area in LKE’s 100% owned Olaroz leases.

Significant corporate transactions continue in adjacent leases with development of Ganfeng Lithium/Lithium Americas Cauchari project with Ganfeng announcing a US$237 million for 37% of the Cauchari project previously held by SQM, followed by a further US$160 million to increase Ganfeng’s equity position to 50% on 1 April 2019, together with a resource that had doubled to be the largest on the planet. Ganfeng then announced a 10 year lithium supply agreement with Volkswagen on 5 April 2019. Nearby projects of Lithium X were acquired via a takeover offer of C$265 million completed March 2018. The northern half of Galaxy’s Sal de Vida resource was purchased for US$280 million by POSCO in June-Dec 2018. LSC Lithium was under offer in Jan 2019 for C$111 million by a mid-tier oil & gas company with a resource size half of Kachi. These transactions imply an acquisition cost of US$55-110 million per 1 million tonnes of lithium carbonate equivalent (LCE) in resources.

The demand for lithium continues to be strong for lithium ion batteries in electric vehicles, according to recent data from the leading independent battery minerals consultant, Benchmark Mineral Intelligence. Demand forecasts indicate the need for an 8x increase in lithium supply in the next 9 years. Supply continues to be constrained, suggesting excellent opportunities for upstream lithium companies.

For more information on Lake, please visit https://www.lakeresources.com.au/home/

About Lilac Solutions

Lilac Solutions is a lithium extraction company based in Oakland, California. Lilac offers a full-service ion exchange technology for lithium extraction from brine resources that is cheap, fast, effective, and environmentally friendly, and that is adaptable to a wide variety of brine chemistries.

It has been working with Lake to transform lithium production with its innovative ion exchange technology for extraction of lithium from brine resources. Lilac deploys unique ion exchange media and related processes to extract lithium from a wide variety of brine resources with high recoveries, minimal costs, and rapid processing times. This approach eliminates the need for evaporation ponds, which are expensive to build, slow to ramp up, and vulnerable to weather fluctuations.

A significant environmental benefit comes from the removal of evaporation ponds, which significantly reduces the footprint of the operation. Further, the method allows for the remaining brine to be reinjected into the same aquifer from where it is sourced, without significantly adjusting the water quality, thereby preserving an aqueous resource in an arid environment.

Lilac’s technology can economically access brines with low lithium concentrations and high concentrations of other salts, such as magnesium. Cost advantages come from reduced time, higher recoveries and a simplified extraction flowsheet with fewer reagents. The technology is modular to suit various project sizes and integrates with conventional plant designs for production of battery-grade lithium carbonate and lithium hydroxide. The technology has been successfully tested with real brine samples from across the Americas.

For more information on Lilac, please visit https://www.lilacsolutions.com/