South Star Battery Metals Announces Successful LiB Results from Completed Cycle Testing and Premium Dispersion Products for Alkaline Battery Markets Superior to Leading Synthetic Graphites

South Star Battery Metals Corp. (" South Star " or the " Company ") (TSXV: STS) (OTCQB: STSBF), along with its technological partner in the United States ("US Lab" 1 ), are pleased to announce the successful final life cycle testing results for over 100 cycles (charging and discharging) in CR2016 LiB coin cells constructed with anode material (coated spherical purified graphite "SPG") produced from the Santa Cruz Graphite Project. In separate test work, a highly conductive dispersion was also tested that exceeds current industry standards for conductive coating applications in both energy storage and advanced purity dry film lubrication markets.

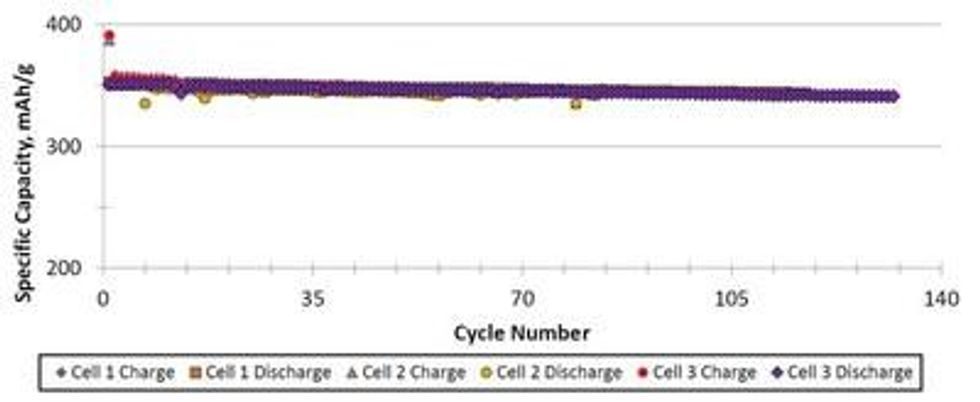

South Star's cycle testing program is complete and exceeded 100 cycles for the LiB cells. One cycle consists of 10 hours of charge and 10 hours of discharge, therefore 100 cycles equal approximately 2,000 hours total. The tests indicate very stable results with approximately 2.2% degradation through 100+ cycles while maintaining reversible capacity on the order of 342 – 345 mAh/g throughout. If these results were projected out, approximately 900 cycles could be achieved before reaching the 20% industry standard cutoff. These results are generally competitive with synthetic graphite and indicates that the Santa Cruz's battery anode material are excellent quality material that are suitable for a variety of LiB applications including EV markets. Upcoming work includes sample preparation of various downstream products so that the qualification process can begin along with processing flowsheet optimizations and performance validation. (Refer to September 22, 2021 press release for results from initial 75 cycles).

In addition, South Star has successfully completed the production and testing of high purity graphite and premium quality electrically conductive dispersions for a variety of applications including the alkaline battery markets. The Santa Cruz material utilized was harvested from the purified graphite rejects from the spheronization process and confirmed that purified flake graphite from the Santa Cruz project is significantly more conductive than industry-leading material currently in use. With the alkaline battery market producing over 12 billion batteries annually and a global market value in excess of US$7.5B in 2020, this application could potentially develop into a key market for South Star.

"We continue to announce stellar value add testing results that prove the premium quality nature of the deposit while advancing towards production in 2022," commented Richard Pearce , President and CEO of South Star. "The final cycle testing with anode materials produced from Santa Cruz concentrates resulted in fantastic performance that approximates the characteristics of synthetic graphite for a broad range of battery applications. In addition, the development of such high-quality conductive dispersions and coatings opens additional value-added markets for our premium graphite. Our material outperformed the leading commercial synthetic graphite products by a considerable margin. Every single alkaline battery manufactured requires graphite, and it is a huge new potential market because of the quality of our concentrates. Premium coatings for alkaline battery cans are currently priced up to $30,000 per tonne. These are excellent outcomes for our program and continue to prove that Santa Cruz can provide a broad array of premium products and bring real value with natural flake graphite to a diversified group of sectors and clients. We have a bright future ahead of us."

Santa Cruz Product Information Bulletins (PIBs) with technical information for the portfolio of products, safety data sheets (SDSs) and marketing materials have been prepared and are being distributed to our existing partners and potential clients. 100-200g samples of a variety of value-add products including micronized and purified graphite, expanded & expandable graphite, dispersions, as well as coated and uncoated SPG are being produced and will be made available for qualification testing.

| 1 The United States laboratory ("US Lab") specializes in advanced graphite materials and value-add testing for battery and non-battery applications. The US Lab company name has not been published for the purposes of preserving a commercial advantage of South Star Battery Metals in the marketplace. |

Lithium-Ion Battery Life Cycle Test Results

Purified graphite was successfully micronized using an advanced pilot scale mechanical milling system outfitted with two air classification circuits. Once the target sizing geometries were achieved, uncoated SPG was produced by rolling and rounding the micronized graphite into elliptical spheres in a specialized mill. The elliptical shapes are a preferred morphology for higher packing density active loadings in battery electrodes. They are also preferred due to better rate capacities, safer and generally longer-life LiBs. Uncoated SPG was coated with a nanolayer of soft carbon and heat treated under a blanket of inert gas. The hardened coating provides a layer of protection from exfoliation and general degradation during the normal expansion and contraction cycles associated with charging and discharging. The coating also reduces ongoing reactions of electrolytes with the graphitic carbon, which results in a reduced battery life ( See June 29 th , 2021 press release for more details).

Next, a copper foil was coated with the anode slurry using the drawdown technique, and the electrode was dried under vacuum and weighed. Finally, the anode was welded to the bottom can of a stainless-steel standard CR2016 coin cell. Three identical coin cells were produced, and testing includes the following: reversible capacity, irreversible capacity, irreversible capacity loss and long-term cycling stability as a function of the elapsed number of charge/discharge cycles.

As shown in Figure 1, other notable positive properties of Santa Cruz anode material are that their reversible capacities are at approximately 342-345 mAh/g through 100 cycles, which is a degradation of 2.2 percent. Assuming the current degradation rate remains constant, Santa Cruz graphite could potentially exceed 900 cycles prior to performance cut-off and provide a viable alternative for the EV sector to synthetic graphite, which has significantly higher costs, higher environmental footprint and is a product derived from petroleum.

Figure 2 presents the results for Cell 3 through cycles 25, 50, 75, 100 and 115 and confirm that the cells maintain excellent electrochemical performance throughout the current testing confirming the robust nature of the Santa Cruz natural crystalline flake characteristics as anode material for lithium-ion batteries.

Figure 2: Cell 3 Cycles 25, 50, 75, 100 & 115 Testing Results

Premium Purity Conductive Coatings

The objective of this phase of testing was to formulate a high-performance, premium-purity graphite-based conductive coating product for the alkaline energy storage market using purified Santa Cruz flake graphite. The electrically conductive coatings require high conductivity, thermal and chemical stability in the presence of corrosive electrolyte (37 wt% KOH), ultra-high purity (99.9+ wt% C) and high crystalline flake structure.

During previous test work, South Star successfully produced purified spherical graphite with a yield of approximately 74% (Refer to news release dated June 29, 2021 ). The remaining 26% of the SPG process byproducts retained their ultra-high purity level (99.9993%) and were homogenized into a composite powder blend with a laser diffraction measured mean particle size of 13.81 um with a broad size range of 0.972 to 104.6 um. This material was then added to a mixing tank equipped with a dispersion blade. Water and surfactants were added to breakdown agglomerates to further reduce the mean particle size to 9.36 um.

US Lab's proprietary wet mill was utilized to achieve further particle size reduction and incorporated a specialized media that allows continued size reduction without cross contamination of the end product with components of the media. The final dispersion had a purity of 99.98+ wt.%C and a mean value of 4.0 um with a D10 = 1.018 um, D50 = 3.55 um and D90 = 8.01 um. The full particle size distribution measured by laser diffraction is shown in Figure 3.

The fine particle dispersion was mixed with a polyacrylate co-polymer resistant to alkaline battery chemistry to produce an alkaline battery can coating meeting current industry standards. Additional water and solvent based polymer binders can be used in future formulations to meet a variety of coating specifications used in lithium primary, lithium-ion batteries, fuel cells and supercapacitors. The final wet Quality Control specifications for the South Star Alkaline Can Coating had the following properties:

| Property | Value | Test Method |

| Viscosity | 425 cps | Brookfield #3 spindle, 20 rpm, 25 o C |

| WPG | 9.53 lb/gal | Weight per gallon |

| pH | 9.6 | |

| Wt.% solids | 8.60% | 30 minutes at 115 o C (vacuum oven) |

A thin coat of the final dispersion was applied to a glass substrate and allowed to dry. The key property of these dried coatings is electrical resistivity in ohm-inches measured by a 2T probe (using a Fluke ohm-meter) on the glass substrate with 1 inch between probes. The South Star graphite dispersion measured electrical resistivity of 20 ohm-inches which is significantly below current industry standards of

About South Star Battery Metals Corp.

South Star Battery Metals Corp. is a Canadian battery metals project developer focused on the selective acquisition and development of near-term production projects in the Americas. South Star's Santa Cruz Graphite Project, located in Southern Bahia, Brazil is the first of a series of industrial and battery metals projects that will be put into production. Brazil is the second-largest graphite-producing region in the world with more than 80 years of continuous mining. Santa Cruz has at-surface mineralization in friable materials, and successful large-scale pilot-plant testing (>30t) has been completed. The results of the testing show that approximately 65% of Cg concentrate is +80 mesh with good recoveries and 95-99% Cg. With excellent infrastructure and logistics, South Star is carrying its development plan towards Phase 1 production projected in Q4 2022, pending financing. South Star trades on the TSX Venture Exchange under the symbol STS, and on the OTCQB under the symbol STSBF.

South Star is committed to a corporate culture, project execution plan and safe operations that embrace the highest standards of ESG principles based on transparency, stakeholder engagement, ongoing education and stewardship. To learn more, please visit the Company website at https://www.southstarbatterymetals.com .

This news release has been reviewed and approved by Richard Pearce, P.E., a "Qualified Person" under National Instrument 43-101 and President and CEO of South Star Battery Metals.

On behalf of the Board,

Mr. Richard Pearce

Chief Executive Officer

Twitter: https://twitter.com/southstarbm

Facebook: https://www.facebook.com/southstarbatterymetals

LinkedIn: https://www.linkedin.com/company/southstarbatterymetals/

YouTube : South Star Battery Metals - YouTube

CAUTIONARY STATEMENT

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

This news release and the Updated Technical Report contain references to inferred resources. The Report is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves.

FORWARD-LOOKING INFORMATION

The information contained herein contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements".

Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: risks related to failure to obtain adequate financing on a timely basis and on acceptable terms; risks related to the outcome of legal proceedings; political and regulatory risks associated with mining and exploration; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company's expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Investors are cautioned against attributing undue certainty to forward-looking statements. These forward-looking statements are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances. Actual events or results could differ materially from the Company's expectations or projections.

SOURCE South Star Battery Metals Corp.

News Provided by Canada Newswire via QuoteMedia