Tempus Resources Ltd is pleased to announce the results of a consolidated metallurgical review completed by JDS Energy & Mining Inc. . The review focussed on the options for processing Elizabeth ore based on the results of a metallurgical test work program completed by G&T Metallurgical Services Ltd. in 2009-2010 at their laboratories in Kamloops, British Columbia HIGHLIGHTS Independent review testing confirms …

Tempus Resources Ltd (“Tempus” or “the Company” ) (ASX:TMR)(TSX.V:TMRR)(OTCQB:TMRFF) is pleased to announce the results of a consolidated metallurgical review completed by JDS Energy & Mining Inc. (“JDS Mining”). The review focussed on the options for processing Elizabeth ore based on the results of a metallurgical test work program completed by G&T Metallurgical Services Ltd. (“G&T Met”) in 2009-2010 at their laboratories in Kamloops, British Columbia

HIGHLIGHTS

- Independent review / testing confirms Elizabeth’s high-grade gold mineralisation is not refractory and high recoveries can be expected from various processing routes

- Two processing routes tested, confirming recoveries of up to ~95%:

- 94.7% recovery into gold doré bars via crushing, grinding, gravity separation and leaching; or

- 92.5-95.1% recovery into high-grade gold concentrate utilising the same processing route employed by the Blackdome Gold Mine plant (ie, crushing, grinding, gravity separation and flotation)

- Future Elizabeth processing options open between use of existing, permitted 300 tonne per day Blackdome Gold Mine process plant or standalone plant options

Tempus President and CEO, Jason Bahnsen, commented “The review work completed by JDS Mining provides further confidence regarding the free milling characteristics of the Elizabeth ore and the value of our existing process plant at Blackdome. As we continue to drill Elizabeth, we will concurrently be progressing the planning and engineering work that will lead to the completion of a Scoping Study / Preliminary Economic Assessment on the project following the release of a maiden Mineral Resource estimate under Tempus’ ownership.”

JDS Mining review of Elizabeth metallurgical results

JDS Mining was appointed to consolidate and complete a review of the historical metallurgical work that has been completed on Elizabeth mineralised material and outline the potential options for future processing of ore from the project. The JDS Mining review was primarily based on test work performed by G&T Met in for J-Pacific gold Inc., a previous owner of the Elizabeth Project.

The objective of the G&T Met testwork was to conduct a preliminary metallurgical assessment of a sample from the Elizabeth Gold Project and determine the suitability of two main processing options, which were:

- utilisation of testing process flow sheet with the same process steps as the existing Blackdome Gold Mine plant (ie, a simulation of utilisation of the Blackdome plant to produce high-grade gold concentrate); and

- looking at the results of standalone processing steps and carrying those through crushing, grinding, gravity separation and then into cyanide leaching to produce gold doré bars (ie, a simulation of a typical carbon-in-leach / carbon-in-pulp circuit).

Composite samples received by G&T Met for their test work program were approximately 21 kilograms from drill core from the South Vein (assaying at 3.95g/t gold and 2.1g/t silver) and approximately 37 kilograms from chip samples from the West Vein (assaying at 0.49g/t gold and 1.0g/t silver). However, it was determined that the assays received from the West Vein were too low grade (not typical of Elizabeth material) and that was excluded from the test program and only used for calibrations when preparing tests for the South Vein composite.

Results from following Blackdome process

Five gravity and flotation tests were conducted to mimic the conditions that would be found in the

Blackdome mill (Tests 1-4 and Test 6). The flotation residence time used was 8 minutes for all of the flotation tests and the reagent scheme employed was methyl isobutyl carbinol (MIBC) as frother and potassium amyl xanthate (PAX) as collector, ie a common flotation reagent scheme and the same as used historically in the Blackdome mill. The tests were conducted following crushing and grinding to a grind size of 120 µm. All 3 tests that included both gravity and flotation after basic crushing and grinding in the flowsheet achieved total gold recoveries of 92.5 to 95.1% (see Tests 3, 4 and 6 in Table 1 below).

Table 1 – G&T Met Flotation and Gravity Results Summary

Test # | Test Description | Gravity | Flotation Concentrate Grade | Total Recovery | |||

Au (g/t) | Ag (g/t) | Au (g/t) | Ag (g/t) | Au (%) | Ag (%) | ||

1 | Flotation Only | 191 | 121 | 89.7 | 77.7 | ||

2 | Gravity Only | 1,692 | 192 | 58.1 | 14.5 | ||

3 | Gravity & Flotation | 2,063 | 368 | 107 | 84 | 93.1 | 76.7 |

4 | Gravity & Flotation | 3,190 | 552 | 83.5 | 76 | 92.5 | 76.5 |

6 | Gravity & Flotation | 6,378 | 50.9 | 95.1 | |||

| Source: G&T Met, February 2010 | |||||||

Mass recovery into gravity concentrates was 0.13-0.20% and mass recovery into flotation concentrates was 1.91-3.10%.

Results from simulated carbon-in-leach / carbon-in-pulp process

Leaching tests were also carried out on the Elizabeth samples to determine the leaching characteristics of the Elizabeth ore through a typical cyanide leach process to simulate the carbon-in-leach / carbon-in-pulp process. This test, Test 5 took the ‘whole rock’ output material following the gravity only test (Test 2) and leached it with sodium cyanide at a concentration of 1,000 ppm over a retention time of up to 48-hours. The results from this test indicate that 87.5% of the remaining gold in the sample was able to be dissolved in cyanide, suggesting a total gold recovery of 94.7% (the silver recovery was not measured in this test). The cyanide consumption was quite low at 0.44kg/tonne .

JDS Mining summary and commentary

In their report, Review of Metallurgical Testwork on the Elizabeth Deposit, dated July 9. 2021, JDS Mining concluded:

“The excellent results for both flotation and leaching demonstrate that the Elizabeth ore is not refractory.”

“The Elizabeth ore and Blackdome ore appear to both contain most of the gold as free particles that are easily liberated and recovered by both flotation or cyanidation. It is JDS’ opinion that processing of these two ores together will not cause a reduction in recovery.”

“It is JDS’ opinion that the Blackdome Mill will be suitable for processing the ore from the Elizabeth deposit, with a few modifications (replace current jigs with centrifugal concentrators, add additional rougher flotation cells to the circuit).”

“The flotation concentrate produced from the Elizabeth ore will be a desirable concentrate

for smelters to purchase.”

“The testwork that has been conducted in 2010 could be considered adequate for a revised PEA unless recent drilling results indicate that the mineralogy, primarily the gold deportment, is significantly different from the samples tested in 2010.”

JDS Mining has recommended some further metallurgical and engineering study work to be completed as part of a forthcoming Preliminary Economic Assessment (“PEA”) on the project. The recommended study work includes:

- A cost review of restarting the Blackdome mill.

- A trade-off study between producing a flotation concentrate versus leaching and producing a dore at with the Blackdome mill or at the Elizabeth site.

- Completion of optical ore sorting testwork of Elizabeth

- A tradeoff study between refurbishing the Blackdome Mill vs building a new facility at Elizabeth.

- Follow up metallurgical testwork to refine the optimal process flowsheet for Elizabeth.

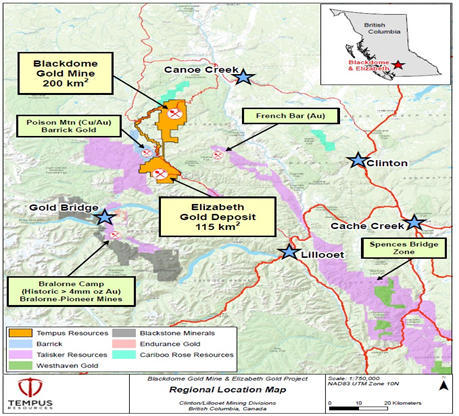

The Elizabeth Gold Project

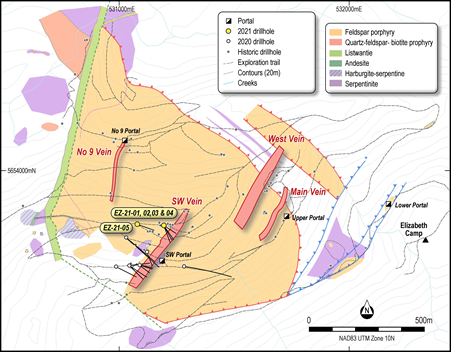

The Elizabeth Gold Project is the Flagship Project for Tempus Resources and is located in the Bralorne – Pioneer Gold District of southern British Columbia (see Figure 1). The 115km 2 project is a relatively underexplored high-grade mesothermal gold mineralisation presenting itself in relatively wide (typically ~1-5m wide) vein sets (see Figure 2). The high-grade quartz veins encountered in the 2020 drilling at Elizabeth show close geological similarities to the Bralorne mesothermal vein system which has been mined to a depth of approximately 2,000 metres from surface and suggests there is strong potential to extend the mineralisation down plunge from the current deepest intersections that are approximately 200 metres below surface.

Tempus began drilling the Elizabeth Project in 2020, releasing initial results on 8 February 2021 that included hole EZ-20-06 which intersected 5.0m at 61.3g/t gold from 116.5m, including 1.5m at 186.0g/t gold from 118.0m. Drilling is ongoing with 8 holes (for approximately 1,800 metres) completed so far since drilling recommenced on 5 June this year. The core samples for the first 4 holes were dispatched to SGS Laboratories in Vancouver for assay on 24 June. Assay results have taken longer than previously guided by the lab. However, latest guidance indicates that they are expected to be received by the end of July.

In the meantime, raw data has also now been received from the airborne magnetic survey covering the whole 115km 2 Elizabeth Project licence area ( see Tempus ASX announcement of 3 June 2021 ). That data is now being processed and reviewed by the Company’s third-party geophysics service provider and the results of their work is expected to be announced in coming weeks.

The airborne magnetic survey will assist in identifying the full extent of Blue Creek Porphyry (host to the high-grade quartz gold mesothermal veins at Elizabeth) beyond its current known extent and surface expression where it is cover by overburden. The magnetic and radiometric expression of the Blue Creek porphyry/Elizabeth Deposit will also be useful in identifying additional exploration targets, potentially similar to Elizabeth, in the license area.

The Blackdome Gold Mine

The Elizabeth Project is joined by a contiguous group of mineral claims to the Blackdome Gold Mine approximately 30 km to the north, including claims covering a potential haul road route between the projects.

The Blackdome process plant was constructed in 1985 with an estimated throughput capacity of approximately 300 tonnes per day. The plant operated at a throughput rate of approximately 200 tonnes per day over a period from 1985 to 1991 producing approximately 230,000 ounces of gold at an average head grade of 22 grams per tonne and a total metallurgical gold recovery averaging over 90%.

The existing process plant at Blackdome consists of a crushing and grinding circuit followed by gravity gold recovery using shaker tables and flotation. The Blackdome process plant has been on care and maintenance since 1991. (see Figure 3)

The Blackdome mill and associated tailings impoundment facility are fully permitted. Tempus owns 100% of both the Elizabeth Gold Project and the Blackdome Gold Mine.

Figure 1 – The Elizabeth / Blackdome Project

Figure 2 – Elizabeth Project Veins

Figure 3 – The Blackdome Process Plant

This announcement has been authorised by the Board of Directors of Tempus Resources Limited.

Competent Persons Statement

Information in this report relating to Exploration Results is based on information reviewed by Mr. Kevin Piepgrass, who is a Member of the Association of Professional Engineers and Geoscientists of the province of BC (APEGBC), which is a recognised Professional Organisation (RPO), and an employee of Tempus Resources. Mr. Piepgrass has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined by the 2012 Edition of the Australasian Code for reporting of Exploration Results, Mineral Resources and Ore Reserves, and as a Qualified Person for the purposes of NI43-101. Mr. Piepgrass consents to the inclusion of the data in the form and context in which it appears.

For further information:

Tempus Resources LTD

Melanie Ross – Director/Company Secretary Phone: +61 8 6188 8181

About Tempus Resources Ltd

Tempus Resources Ltd (“Tempus”) is a growth orientated gold exploration company listed on ASX (“TMR”) and TSX.V (“TMRR”) and OTCQB (“TMRFF”) stock exchanges. Tempus is actively exploring projects located in Canada and Ecuador. The flagship project for Tempus is the Blackdome-Elizabeth Project, a high grade gold past producing project located in Southern British Columbia. Tempus is currently midway through a drill program at Blackdome-Elizabeth that will form the basis of an updated NI43-101/JORC resource estimate. The second key group of projects for Tempus are the Rio Zarza and Valle del Tigre projects located in south east Ecuador. The Rio Zarza project is located adjacent to Lundin Gold’s Fruta del Norte project. The Valle del Tigre project is currently subject to a sampling program to develop anomalies identified through geophysical work.

Forward-Looking Information and Statements

This press release contains certain “forward-looking information” within the meaning of applicable Canadian securities legislation. Such forward-looking information and forward-looking statements are not representative of historical facts or information or current condition, but instead represent only the Company’s beliefs regarding future events, plans or objectives, many of which, by their nature, are inherently uncertain and outside of Tempus’s control. Generally, such forward-looking information or forward-looking statements can be identified by the use of forward-looking terminology such as “plans”, “expects” or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, or “believes”, or variations of such words and phrases or may contain statements that certain actions, events or results “may”, “could”, “would”, “might” or “will be taken”, “will continue”, “will occur” or “will be achieved”. The forward-looking information and forward-looking statements contained herein may include, but are not limited to, the ability of Tempus to successfully achieve business objectives, and expectations for other economic, business, and/or competitive factors. Forward-looking statements and information are subject to various known and unknown risks and uncertainties, many of which are beyond the ability of Tempus to control or predict, that may cause Tempus’ actual results, performance or achievements to be materially different from those expressed or implied thereby, and are developed based on assumptions about such risks, uncertainties and other factors set out herein and the other risks and uncertainties disclosed under the heading “Risk and Uncertainties” in the Company’s Management’s Discussion & Analysis for the quarter and nine months ended March 31, 2021 dated May 14, 2021 filed on SEDAR. Should one or more of these risks, uncertainties or other factors materialize, or should assumptions underlying the forward-looking information or statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected. Although Tempus believes that the assumptions and factors used in preparing, and the expectations contained in, the forward-looking information and statements are reasonable, undue reliance should not be placed on such information and statements, and no assurance or guarantee can be given that such forward-looking information and statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such information and statements. The forward-looking information and forward-looking statements contained in this press release are made as of the date of this press release, and Tempus does not undertake to update any forward-looking information and/or forward-looking statements that are contained or referenced herein, except in accordance with applicable securities laws. All subsequent written and oral forward-looking information and statements attributable to Tempus or persons acting on its behalf are expressly qualified in its entirety by this notice. Neither the TSX Venture Exchange nor its Regulation Service Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

SOURCE: Tempus Resources Ltd

View source version on accesswire.com:

https://www.accesswire.com/655987/Elizabeth-Gold-Project–Metallurgical-Result

News Provided by ACCESSWIRE via QuoteMedia