In an exclusive interview with Lithium Investing News, Daniela Desormeaux, General Manager of SignumBOX, discussed some of the most important characteristics for a lithium mining company. A trained economist and expert in industrial chemicals and natural resources, she explained the premium associated with the quality of the deposit in terms of economic feasibility and profitability.

In an exclusive interview with Lithium Investing News, Daniela Desormeaux, General Manager of SignumBOX, a Chilean based market research firm focused on natural resources, chemicals and technology on a global scale, discussed some of the most important characteristics for a lithium mining company. A trained economist and expert in industrial chemicals and natural resources, she explained the premium associated with the quality of the deposit in terms of economic feasibility and ultimately the profitability.

Specific conditions must also be considered. “In the case of the projects that are based in lithium brines, it is also important to know the evaporation rate of the site because it will determine the evaporation pond area. In a lithium project, the evaporation ponds represent more or less 50 percent of the cost of the project.”

The ponds

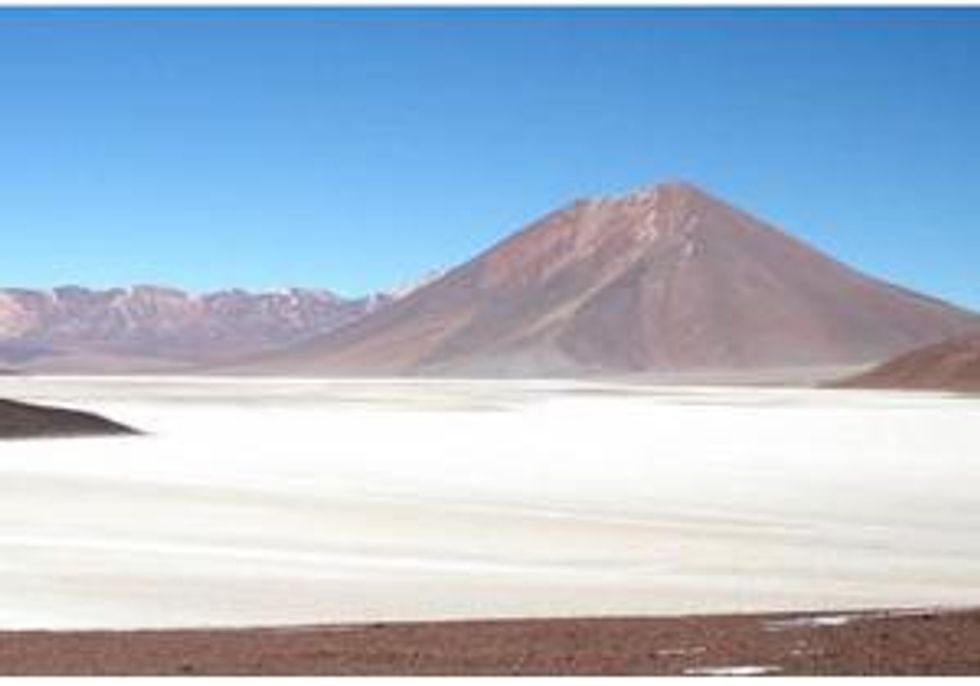

As a result of relatively dilute concentrations of lithium in even the most favorable brines, and the more cost prohibitive expense of directly recovering lithium in a processing plant, solar evaporation of the brine is necessary to further concentrate. Intrinsically, solar evaporation should be a relatively simple and inexpensive operation, but it does have a number of demanding requirements and many challenges can arise.

Since it relies upon solar radiation for the energy to evaporate water from the brine, the pond areas require large comparatively flat and inexpensive real estate. These conditions are relatively easy to meet; however, the pond design demands careful construction, operation and control. To be most cost-effective the ponds must be divided into many segments to maximize the overall evaporation rate—as the rate decreases with the concentration—so that each of the salts in the brine may crystallize in separate ponds. Ponds may be periodically taken out of service to harvest and remove these salts, without undue disruption to the entire system. There must be as much gravity flow between the ponds as possible and the banks must be protected from wave erosion.

Construction and design

Most importantly, ponds must be designed to be as leak-free as possible. If the ponds are constructed of soil, a careful soil survey must first be made of the entire pond area to be sure that there is a continuous layer of adequately impermeable clay under the pond, at least at a reasonable depth. If there are occasional zones of permeable soil it must be removed and back filled with clay. If the clay layer occurs at depth, then the outer pond walls must be cut with a trench and backfilled with clay to prevent the upper porous zones from leaking laterally. Meandering former sandy stream beds may also require sealing with clay cut off beds.

In cases where the soil permeability is of border-line value, canals may be built adjacent to the outer walls and filled with a more dilute brine at a higher level than in the ponds to form a hydraulic seal. In this case, the ponds are usually operated with the feed brine at the outer edges of the pond system and the product brine in the center. For most of the world’s large salars and playas, satisfactory areas of impermeable soil can be found to form a solar pond system with a reasonably low amount of leakage.

An alternative to clay sealed ponds are operations that are lined with an impermeable plastic membrane. The most demanding pond areas may use a reinforced chlorosulfonated polyethylene synthetic rubber noted for its resistance to chemicals, temperature extremes and ultraviolet light. It is highly puncture resistant and has a very long service life of over 25 years, assuming low to moderate concentrations of magnesium chloride in the brine. For the bulk of the ponds a much less expensive but less rugged membrane might be used such as 20 – 40 mil polyvinyl chloride (PVC) or polypropylene. In theory, the membranes can create a leak-free pond, but practically it is often not realistic. The primary issue is that these sheets can only be factory-produced with a limited width and they may have some small holes in them as they are formed. The membranes are relatively heavy, which provides challenges and limits the size of each piece. This requires that strips of membrane must be joined together and sealed to form the pond size requirement.

The more durable sheets are joined with an adhesive, while PVC and most other polypropylene membranes can be heat sealed. Both jobs are difficult and the risk of imperfect seals is always a consideration, as well as the potential of punctures from underlying rocks or tears as the membrane is stressed.

Leakage prevention

Careful visual inspection as well as some electric testing can find some leaks, and once the ponds become filled with water, moisture or conductivity sensors in the soil can locate other leaks which can be repaired before ponds are operational.

Ultimately, leakage prevention is critical particularly because of the relatively dilute concentration of lithium in the original brine. There are a number of methods that are employed including various electrical measurements in order to detect moisture in the soil. Piezometers, which are small open ended tubes that can measure hydrostatic pressure, are also sometimes utilized.

The most effective method seems to employ small porous tubes placed under the surface of the ponds, where samples of the leak can be withdrawn by a vacuum process. In any of these cases, it is very challenging to find the exact location of the hole and then repair the membrane.

Despite the issues and additional expense, membrane linings can provide superior brine retention and often yield superior performance to clay lined solar ponds.