New York Lithium-Ion Gigafactory To Be In Huron Campus

Magnis Resources Limited (“Magnis” or the “Company”) (ASX:MNS) is pleased to announce that Huron Campus will be the primary manufacturing location for the New York State Lithium-ion Battery Gigafactory Consortium as per the Company’s announcement on 22 May 2017. An agreement has been signed by consortium partners with officials from the Huron Campus. ABOUT THE HURON …

Magnis Resources Limited (“Magnis” or the “Company”) (ASX:MNS) is pleased to announce that Huron Campus will be the primary manufacturing location for the New York State Lithium-ion Battery Gigafactory Consortium as per the Company’s announcement on 22 May 2017. An agreement has been signed by consortium partners with officials from the Huron Campus.

ABOUT THE HURON CAMPUS

Located at Endicott near Binghamton, New York, the Huron Campus is the Birthplace of IBM, and it is a world class high tech facility which was previously used by IBM (NYSE: IBM) for the manufacture of equipment, including, high end circuit boards, semiconductor packaging, and advanced electronics. The facility is ideal for the manufacture of both battery materials and batteries/cells alike, as it has temperature and humidity controlled buildings and warehouse facilities ready to integrate new technologies. The site has a transmission level substation with 50MW of capacity, and the Campus supplies low-cost power.

The Huron Campus contains technology, specialised equipment, an experienced team, and nearly 100 years in logistics business expertise – all key contributors in shortlisting and choosing this site.

The Campus covers 150 acres, and the building earmarked for the manufacture of the consortia’s batteries totals 60 acres.

State-of-the-art facilities include site feed from two independent substations. A large central powerhouse delivers steam, compressed air and chilled water to the site. Compressed air is dried to -27 Celsius.

In recent months, members of the consortium visited the Huron Campus and were impressed with its facilities. Other current tenants include IBM, BAE Systems, Geodis, and Cadence Design Systems in combination with existing roll-to-roll manufacturing system among others.

Figure 1: Aerial photo of a section of Huron Campus

Huron Campus President Christopher J. Pelto commented: “Huron Campus is an ideal place to start and grow advanced technology manufacturing initiatives. We have our own central utility plant, high purity water systems, 2MM/gal per day waste water treatment facility for treatment or recycling, inter-building material transfer/handling system, loading/unloading docks to handle hundreds of thousands of tonnes of material annually and a commercial rail line going in between the campus in combination with the automated material handling which could accelerate the battery manufacturing plant. We are very excited and happy to offer our support to the consortium for this initiative.”

Chairman of Magnis Resources Frank Poullas commented: “Today’s announcement shows the commitment of the consortium towards fast tracking the production of Lithium-ion batteries. There’s no doubt that there are many Lithium-ion battery plants being currently built and speed to market is important to capture the advantages of the consortium’s materials and technologies. The recent announcements are the result of significant investment in time and effort over recent years by consortium members. The selection of the Huron site provides a springboard to further accelerate these efforts towards future battery production.”

Figure 2: Huron private water treatment plant (bottom Left) and central utility plant (bottom right)

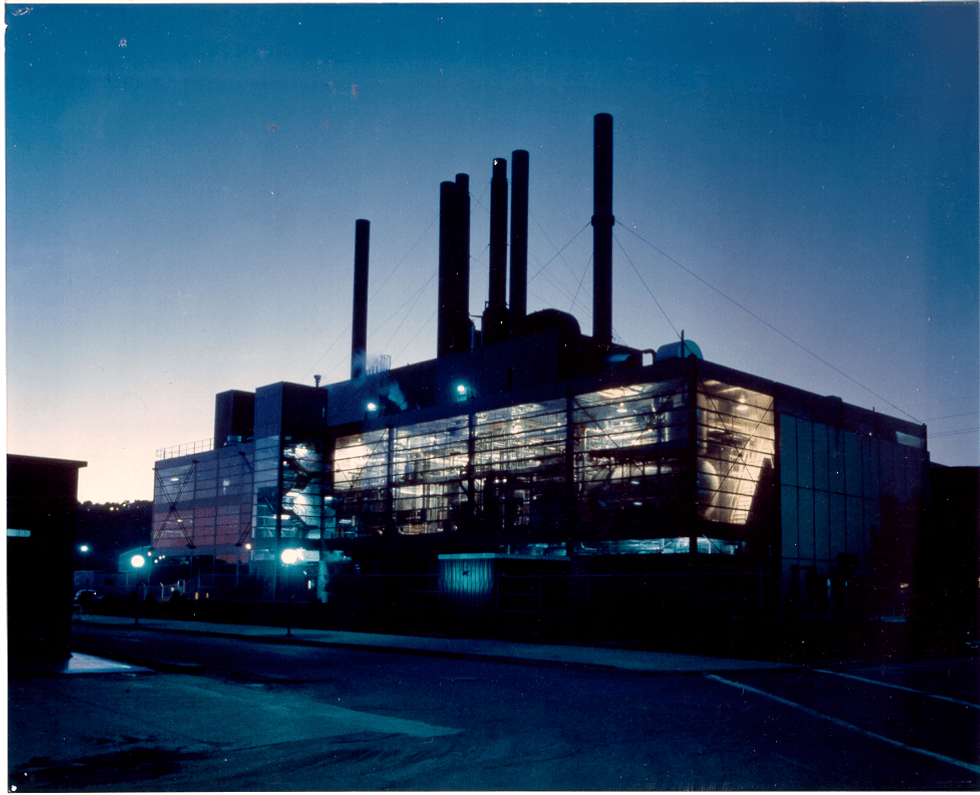

Figure 3: Huron Powerhouse

Figures 4 and 5: Modern Facilities of Huron Campus

Global Consortium

The consortium includes New York based Charge CCCV (C4V), Primet Precision Materials, C&D Assembly and Australian based Boston Energy and Innovation along with Magnis Resources.

The consortium includes members involved in producing batteries and has the all the expertise and capabilities needed for Lithium-ion Battery (LIB) manufacture from raw materials, to particle engineering, to manufacturing expertise to financing.

Scoping Study and Offtake

An internal scoping study on LIB manufacture in New York and other jurisdictions has been undertaken and completed to assess the key project aspects, which included battery market forecasting, raw materials supply, material technologies, manufacturing processes, key stakeholders and financial viability. The scoping study was initiated by Magnis and C4V who have been collaborating for over 18 months and harnessed input from all consortium members in the operational supply chain and project funding. The outcomes of the scoping study were instrumental in bringing all consortium members together to fast track the 15GWh LIB plant in New York towards future production.

In recent months, sample batteries have been produced by the consortium members for potential customers. Discussions with these customers are progressing well and include advanced discussions on future offtake agreements.

For further information:

Frank Poullas

Chairman

Magnis Resources Limited

+61 2 8397 9888

www.magnis.com.au

Source: www.magnis.com.au