Leading Edge Materials Produces Expandable Graphite In Line With Current Market Products from Woxna, Sweden

Leading Edge Materials Corp. (“Leading Edge Materials” or the “Company”) (TSXV:LEM, OTCQB:LEMIF, Nasdaq First North:LEMSE) is pleased to announce the successful completion of the first phase of test work to manufacture expandable graphite using material from the Woxna graphite mine in Sweden.

Leading Edge Materials Corp. (“Leading Edge Materials” or the “Company”) (TSXV:LEM, OTCQB:LEMIF, Nasdaq First North:LEMSE) is pleased to announce the successful completion of the first phase of test work to manufacture expandable graphite using material from the Woxna graphite mine in Sweden. Expandable graphite provides potential for creation of additional value-added products from Woxna.

Key Points:

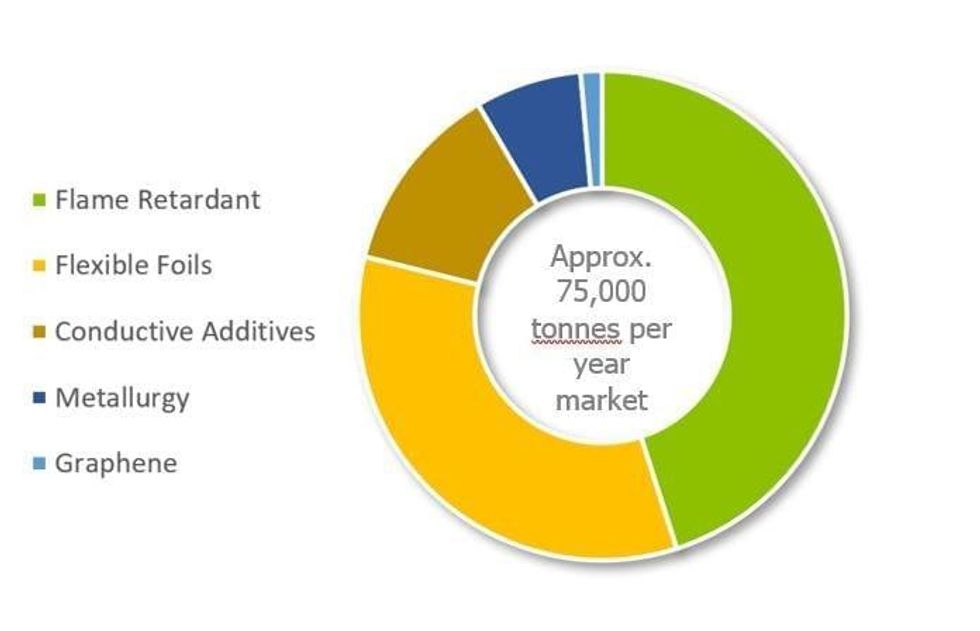

Expandable Graphite Applications (CNW Group/Leading Edge Materials)

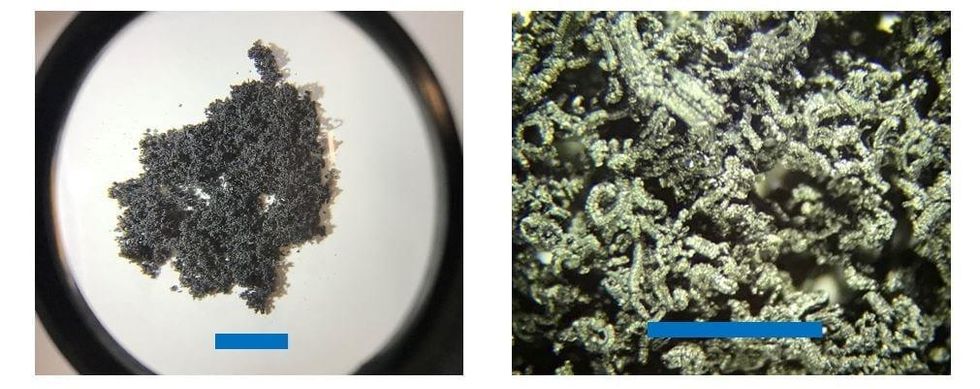

Expandable Graphite Manufactured in Europe Using Woxna Graphite – Approximate Scale Bar shown: left = 10mm, right = 3mm (CNW Group/Leading Edge Materials)

- Expandable graphite has been produced and tested, with its performance in-line with commercially available materials currently in the market;

- Expandable natural graphite is a critical industrial material, with a significant and growing market for fire resistant building products, textiles and graphite foils;

- The manufacturing methods tested did not require the use of toxic chemicals;

- Pricing of expandable graphite is based on flake size, expansion ratio and purity, and lies in the range of US$2000 – US$4000 per tonne;

- Provides the potential for creation of additional value-added products from the Woxna graphite mine in Sweden;

Research was completed in Germany with leading consultancy ProGraphite GmbH (“ProGraphite”). ProGraphite used run-of-mine +80 mesh (>180 micron) material from the Woxna mine to test a range of standard process variables. Testing demonstrated that a combination of sulphuric acid and potassium permanganate delivered optimal results, expanding up to 215 ml/g (480 times) when heated to 1000°C.

This degree of expansion is in line with expandable graphite products available in the market today. Additional process optimization and product improvement is anticipated through further research. The methods tested did not require the use of toxic chromium, lead, or bromine-bearing chemicals that are used in the manufacture of some Chinese expandable graphites.

Mr. Mark Saxon, Interim CEO stated, “Expandable graphite is a high value application for graphite flakes that are larger in size and of a lower purity than that required for battery anode materials. The work completed by ProGraphite using stockpiled material from the Woxna mine has demonstrated that our material expands in line with current commercial products, using a process that does not require any toxic chemicals.

We will continue to pursue this research in parallel with our battery anode materials, which provides potential for additional value-added products. Please contact the Company to receive expandable graphite samples from the Woxna mine.”

Expandable graphite exploits the remarkable anisotropic property of natural flake graphite. Mild non-toxic chemicals (in this case sulfuric acid) are positioned between individual graphite flakes, which when exposed to heat converts from a solid or liquid to a gas phase causing a dramatic accordion-like expansion.

Expandable Graphite Applications

Expandable natural graphite is a critical industrial material, with a significant and growing market. Current market size is estimated to be 70,000 to 80,000 tonnes per year, with approximately 45% of demand coming from manufacture of fire-resistant materials. Other market segments include flexible foils, conductivity additives, and a small volume as a graphene manufacturing pre-cursor.

Demand for expandable graphite for fire resistant building products and textiles are both substantial and fast growing. When incorporated in building materials and plastics, the dramatic expansion on heating greatly reduces product flammability, as the expanded graphite forms a protective barrier in the event of fire. Globally, governments are moving to restrict use of flammable building materials, with the China Building Materials Application Technology Research Institute stating in 2018 “China needs 4 0 million tonnes of fire-retardant building materials per annum, which will contain 5% expandable graphite.”

In addition to fire resistant building materials, expanded graphite is an important pre-cursor for the manufacture of flexible graphite foils and papers which provide very light weight heat dispersion and shielding properties. The low density expanded graphite is rolled and compressed into thin flexible sheets which provide high heat, corrosion and compression resistance. Graphite foils are incorporated in many mobile electrical devices to safely disperse heat away from the battery source. Rapid demand growth is forecast due to the increasing use of high energy density batteries in mobile devices. Emerging markets also exist for expandable graphite as a precursor for graphene manufacturing.

Pricing of expandable graphite is based on flake size, expansion ratio and purity, and lies in the range of US$2000 – US$4000 per tonne. Of note, the purity requirements for expandable graphite is substantially lower than battery materials. Leading Edge Materials is now preparing for follow up test work with increased sample size to optimize process conditions and material economics.

On behalf of the Board of Directors, Leading Edge Materials Corp.

Mr. Mark Saxon, Interim CEO

About Leading Edge Materials

Leading Edge Materials is a Canadian public company focused on production of high value critical raw materials for the European market, with an operating base in the Nordic region, a region well recognized for its promotion and investment in innovation. LEM’s flagship asset is the Woxna Graphite production facility located in central Swedentargeting the supply of specialty materials for lithium ion battery production. LEM’s assets and research focus are towards the raw materials for Li-ion batteries (graphite, lithium, cobalt); materials for high thermal efficiency building products (graphite, silica, nepheline); and materials that improve the efficiency of energy generation (dysprosium, neodymium, hafnium). Investments are linked to the global shift to low-carbon energy generation and energy storage.

Additional Information

The information was submitted for publication through the agency of the contact person set out above, at 30th of July, 2019, at 4:30 am Vancouver time.

Leading Edge Materials is listed on the TSXV under the symbol “LEM” and Nasdaq First North Stockholm under the symbol “LEMSE”. Mangold Fondkommission AB is the Company’s CA on Nasdaq First North and may be contacted at +46 (0) 8 5030 1550.

Reader Advisory

This news release may contain statements which constitute “forward-looking information”, including statements regarding the plans, intentions, beliefs and current expectations of the Company, its directors, or its officers with respect to the future business activities of the Company. The words “may”, “would”, “could”, “will”, “intend”, “plan”, “anticipate”, “believe”, “estimate”, “expect” and similar expressions, as they relate to the Company, or its management, are intended to identify such forward-looking statements. Investors are cautioned that any such forward-looking statements are not guarantees of future business activities and involve risks and uncertainties, and that the Company’s future business activities may differ materially from those in the forward-looking statements as a result of various factors, including, but not limited to, fluctuations in market prices, successes of the operations of the Company, continued availability of capital and financing and general economic, market or business conditions. There can be no assurances that such information will prove accurate and, therefore, readers are advised to rely on their own evaluation of such uncertainties. The Company does not assume any obligation to update any forward-looking information except as required under the applicable securities laws.

Woxna has never defined a mineral reserve and the previous preliminary economic assessment on Woxna dated October 29, 2013, has been superseded by the Company’s current technical report dated May 11, 2015. As the Woxna facility is not in production but remains on a production ready status, any future decision to recommence mining at Woxna will not be based on a preliminary economic assessment demonstrating the potential viability of mineral resources or feasibility study of mineral reserves demonstrating economic and technical viability. Under these circumstances, there is increased risk of technical and economic failure for the Woxna project, and the Company discloses additional risk factors relating thereto. The Company advises that it has not based its production decision on a feasibility study of mineral reserves, demonstrating economic and technical viability, and, as a result, there may be an increased uncertainty of achieving any particular level of recovery of minerals or the cost of such recovery, including increased risks associated with developing a commercially mineable deposit. Historically, such projects have a much higher risk of economic and technical failure. There is no guarantee that production will begin as anticipated or at all or that anticipated production costs will be achieved. Failure to commence production would have a material adverse impact on the Company’s ability to generate revenue and cash flow to fund operations. Failure to achieve any anticipated production costs would have a material adverse impact on the Company’s cash flow and future profitability. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Source: www.newswire.ca