Alabama Graphite Obtains 99.99% Cg Purity from Coosa Project

Alabama Graphite Corp.’s (AGC) announced purities of 99.99 per cent graphitic carbon have been obtained from preliminary studies testing the purification of the graphite concentrates from the 100-per-cent-owned Coosa graphite project, located in Coosa county, east-central Alabama, United States.

Alabama Graphite Corp.’s (TSXV:ALP) announced purities of 99.99 per cent graphitic carbon have been obtained from preliminary studies testing the purification of the graphite concentrates from the 100-per-cent-owned Coosa graphite project, located in Coosa county, east-central Alabama, United States.

As quoted in the press release:

Graphite concentrates of 99.99% Cg purity were achieved using a conventional low-temperature thermal purification process at one of North America’s premier metallurgical laboratories (For reasons of commercial confidentiality, Alabama Graphite Corp. is not disclosing the identity of the metallurgical laboratory contracted for the Company’s ongoing graphite purification work). The purification trials were conducted on graphite concentrates produced by SGS Mineral Services (“SGS”) of Lakefield, Ontario. The trials were based on a total product mix and were carried out across the total flake-size distribution (including, large-, medium- and fine-flake size fractions), in order to achieve a full-spectrum sampling of the Coosa Graphite Project’s graphitic material and its demonstrated purity.

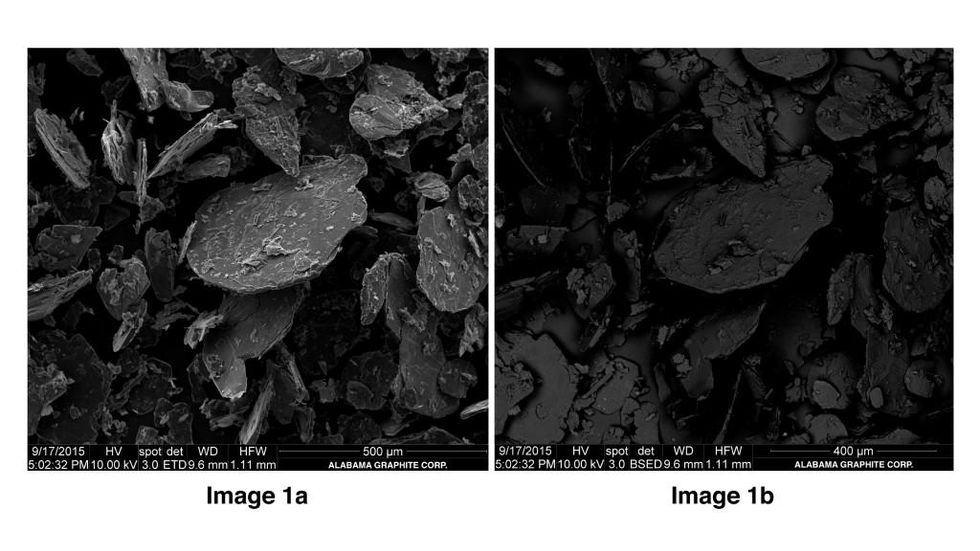

Figure 1: Image 1a: A secondary electron SEM micrograph of Alabama Graphite Corp.’s 99.99% Cg purified graphite flake concentrate. Image 1b: Image 1b was taken at the exact same time as Image 1a, but using the backscattered electron detector. Backscattered electron imaging is used to differentiate between materials of different compositions – phases heavier than carbon will look bright, and pure carbon will look grey, as seen here. The even coloration demonstrates the capabilities of the Alabama Graphite Corp. purification process in producing 99.99% Cg purified graphite flake concentrate.

Alabama Graphite Co-Chief Executive Officer, Donald Baxter, P.Eng., stated:

Today marks another major milestone for AGC. The achievement of 99.99% Cg from the initial run of purification testing – without any optimization – only reaffirms our belief in the exceptional quality of the graphite material hosted on our Coosa property. These high-purity levels are required for graphite used in many high-value applications, namely Lithium-ion batteries for use in electric vehicles and grid storage/stationary batteries, but also in portable electronic applications, which represent a significant and growing market with enduring future demand.

AGC will now move forward with larger scale testing designed to optimize the purification process and further improve these excellent results. We have now begun sizing (micronization), shaping (spheronization) and carbon coating of our Coosa graphite material – known as coated spherical natural graphite or CSPG (see the Company’s June 25, 2015 announcement) – to meet the requirements for use in Li-ion batteries, specifically for electric vehicles.