Zinc One CEO: We Have a Clear Path to Development at the Bongará Zinc Project

Zinc One CEO Bill Williams provides insight on zinc and delineates the work being done to advance the Bongará zinc project.

Zinc One (TSXV:Z,FWB:RH33,OTCMKTS:ZZZOF) CEO Bill Williams believes that the company has a clear path to development at the Bongará zinc project in Peru.

In the interview below, Williams discussed the work he and his team have been conducting at the project, including the highlights of the extensive drilling program that took place this year. He also spoke to the uses of zinc in the global economy and what lies in the future for the base metal.

Below is a transcript of our interview with Zinc One CEO Bill Williams. It has been edited for clarity and brevity.

Investing News Network: Please give our investor audience an overview of Zinc One and its flagship projects in Peru.

Zinc One CEO Bill Williams: Zinc One has a 100 percent interest in the Bongará zinc project, which also includes an area named Charlotte-Bongará. This project offers a quick path to development with significant upside. We have near-surface mineralization, which has yet to be fully delineated. This was a mine 10 years ago that produced for a couple of years, and there is still a lot to be delineated and potentially mined in the future.

INN: Are there any exploration highlights from your 2018 exploration program that investors should take note of?

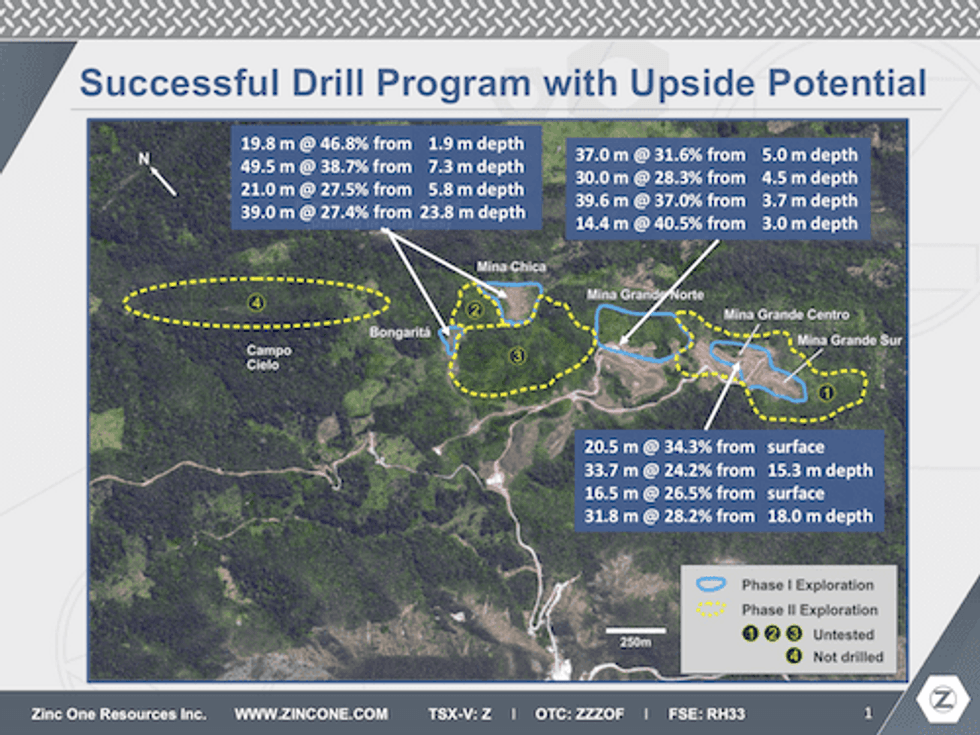

BW: We have drilled 264 holes, covering 7,831 meters in an area of about 1.4 kilometers in length. One of our best intercepts was of 49.5 meters of 38.7 percent zinc, from five meters of depth. This shows incredible near-surface mineralization as well as outcropping mineralization. The highlight of our drill program was the discovery of the Mina Chica deposit, which hosts that exciting intercept.

We went into this project with a historic resource of about 1.1 million tonnes at a grade of 21 percent zinc. Mina Chia is a very small part of that, because they only looked at the surface mineralization when they did their estimation. That means this new deposit should make a significant addition to the overall resource estimate, which we plan to release in the beginning of January 2019.

INN: What attracted you to the project?

BW: I’ve known about this project for quite some time, as I have lived and worked in Peru for a few years and have been familiar with that has been taking place in the industry. I became involved with the project just over two years ago and found it fascinating. We have a clear path to development and have the permitting on track to be in production by no later than early 2021. There aren’t many other companies out there that can move that fast.

Another benefit of the project is that it is scalable. We anticipate that we will be extending that 1.1 million-tonne resource with the publication of our NI 43-101-compliant resource in January. We are also currently permitting 583 drill holes to delineate the areas we have just drilled and to do further exploration along the 1.4-kilometer ridge, which will allow us to potentially add more contained zinc to our current inventory.

Zinc One’s strategy has been to access the property right near the end of a mine closure operation. We suspended the mine closure, then took control of the mine and the concession. As such, we are trying to reactivate the mine under the old permit, which will be modified and improved to meet current standards.

INN: What are the typical uses of zinc?

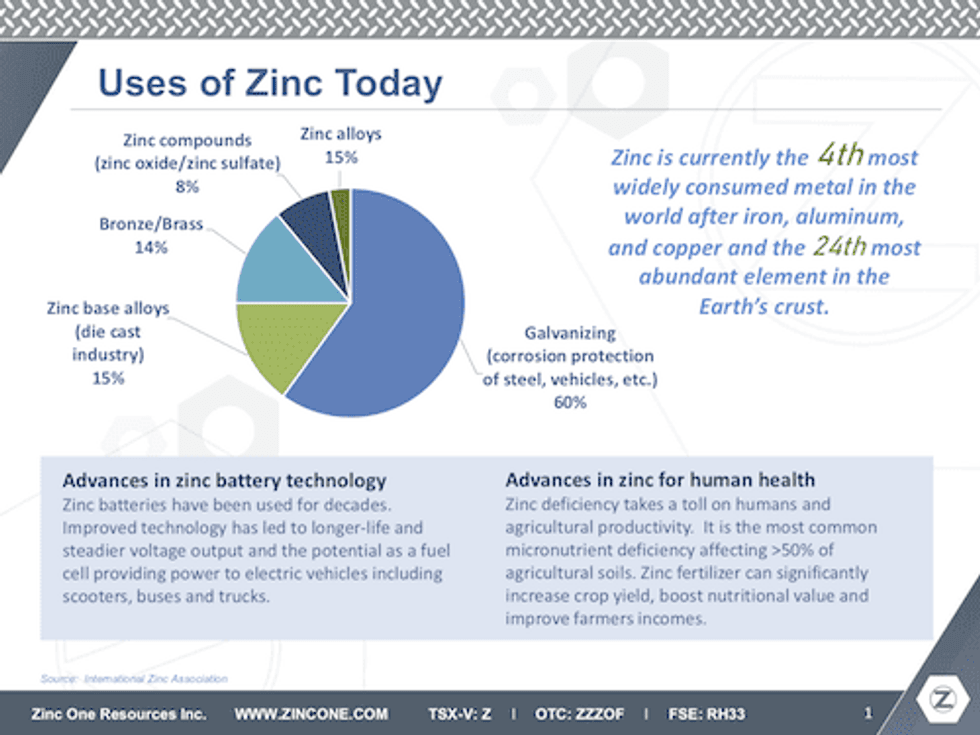

BW: The most common use of zinc is for the galvanization of steel as it prevents rusting. In the future, we will have to look to alternative uses, such as the increased use of zinc in batteries. Zinc batteries have been around for a while, but need to be improved and made more efficient in order to become mainstream.

Another use of zinc is also in crop fertilization, particularly to increase crop productivity. This is a really important application that showcases how human beings need zinc in their system to live, and live well. These are the things we are looking forward to for zinc use.

INN: What is the difference between zinc oxide and zinc sulfite and how does that affect the choice of processing methods?

BW: They use different processing methods. Zinc sulfite is commonly mined, and has been done for some time, with the use of a conventional flotation process. This process extracts the zinc using some basic chemicals that make the zinc sulfite minerals float and develop a concentrate.

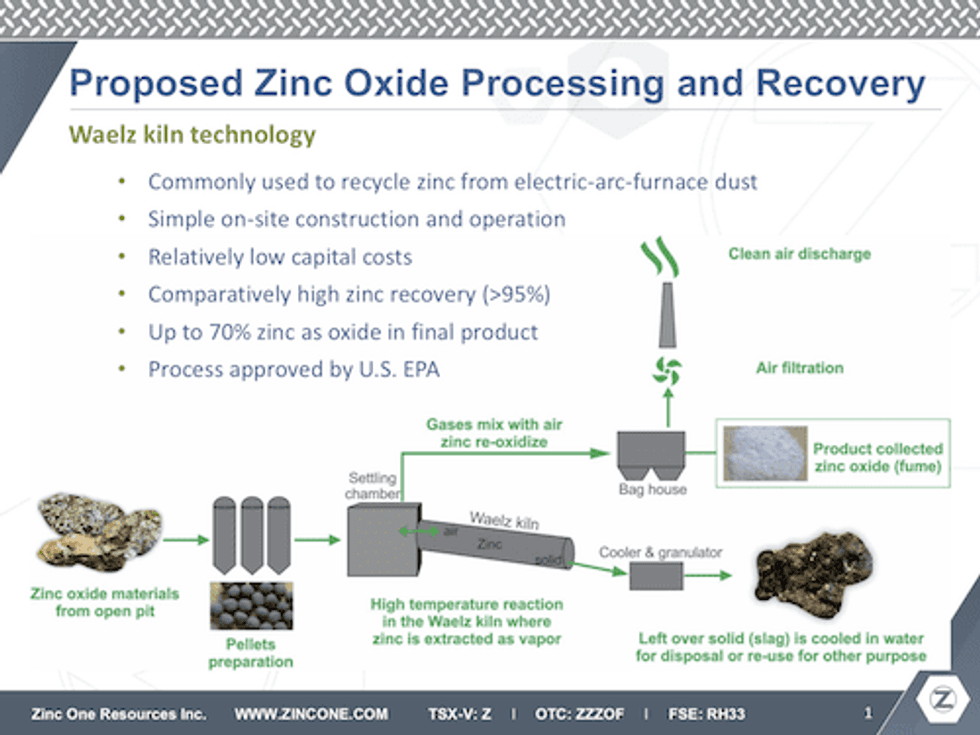

For zinc oxide, flotation is not a very efficient method. The best way to extract zinc from an oxide, carbonate or silicate is pyrometallurgy. This is a well-known process that is used throughout the world to recycle zinc from electric arc furnace dust from steel mills, in the form of a Waelz kiln. This kiln is a low-temperature cement plant from which you can get 70 percent zinc, which, as an oxide in a concentrate, is marketable.

CEO interviews are part of investor education campaigns for clients advertising on the Investing News Network. Important news is contextualized by CEOs, and the resulting interviews are disseminated to the Investing News Network audience because they have value to market watchers.

The Investing News Network interviews a CEO for an understanding of their perspective on the company, the investment potential of the company and market news related to the company. The information contained here is for information purposes only and is not to be construed as an offer or solicitation for the sale or purchase of securities.