November 29, 2024

Provaris (ASX:PV1), a leading innovator in the green hydrogen sector is well-positioned to be an important part of the European green hydrogen supply chain through its groundbreaking compressed hydrogen solutions. The company's proprietary tank IP and innovative ship design support its vision to develop a portfolio of integrated green hydrogen projects.

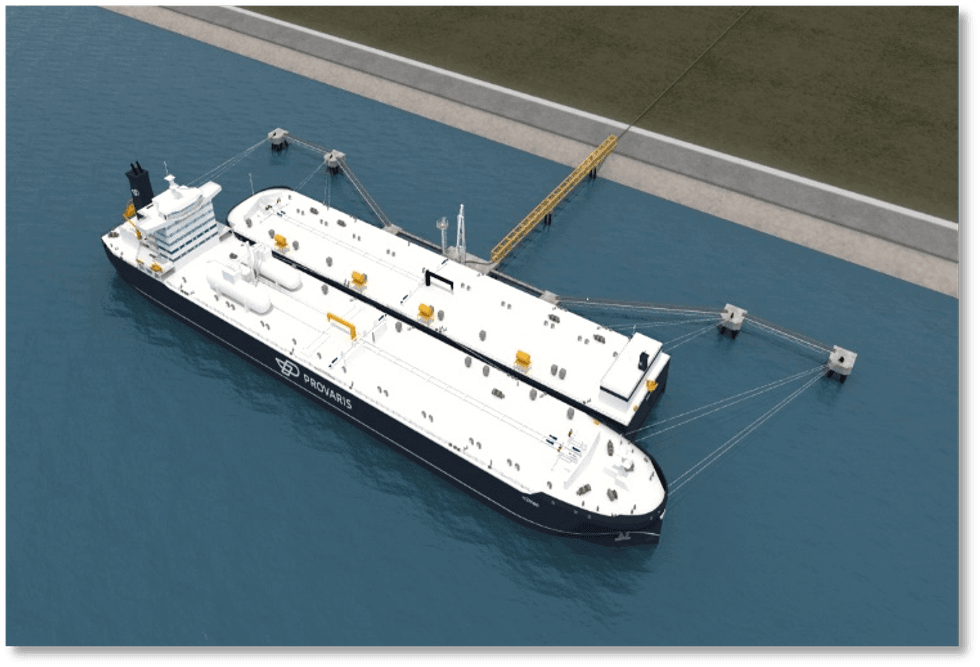

Provaris’ innovative H2Neo carrier solution offers a more efficient and cost-effective alternative to traditional methods of hydrogen storage and transport. These carriers are designed to address the growing global demand for clean energy while overcoming the logistical challenges associated with green hydrogen distribution.

Provaris is expanding its portfolio to include CO2 storage technologies, a move that aligns with the company's core competencies in gas handling and storage, while addressing the growing demand for large scale CO2 storage and transport solutions in the European market, and beyond.

Company Highlights

- Provaris is a leading innovator in the green hydrogen sector, leveraging its proprietary compressed hydrogen technology to develop sustainable, clean energy supply chains across Europe.

- The company combines proven technology and unique IP for cost-effective hydrogen storage and transport solutions, with a first-mover advantage through its proprietary ship design and low-cost delivery.

- Provaris has established strong strategic partners across Europe, enhancing its credibility in delivering hydrogen to market

- In addition to green hydrogen, the company is leveraging its tank IP for application into the established CO2 storage and shipping market.

This Provaris Energy profile is part of a paid investor education campaign.*

Click here to connect with Provaris Energy (ASX:PV1) to receive an Investor Presentation

PV1:AU

Sign up to get your FREE

Provaris Energy Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

The Conversation (0)

25 May 2025

Provaris Energy

Enabling the scale-up of clean energy supply chains through innovative hydrogen and CO2 storage and transport solutions.

Enabling the scale-up of clean energy supply chains through innovative hydrogen and CO2 storage and transport solutions. Keep Reading...

05 February

LCO2 Tank FEED Achieves Key Milestones

Provaris Energy (PV1:AU) has announced LCO2 Tank FEED Achieves Key MilestonesDownload the PDF here. Keep Reading...

01 February

MOU with Yinson and Himile to Advance LCO2 Tank Production

Provaris Energy (PV1:AU) has announced MOU with Yinson and Himile to Advance LCO2 Tank ProductionDownload the PDF here. Keep Reading...

30 January

Quarterly Activities/Appendix 4C Cash Flow Report

Provaris Energy (PV1:AU) has announced Quarterly Activities/Appendix 4C Cash Flow ReportDownload the PDF here. Keep Reading...

17 December 2025

Placement Advances H2 and CO2 Tank Development

Provaris Energy (PV1:AU) has announced Placement Advances H2 and CO2 Tank DevelopmentDownload the PDF here. Keep Reading...

15 December 2025

Trading Halt

Provaris Energy (PV1:AU) has announced Trading HaltDownload the PDF here. Keep Reading...

17 February

RZOLV Technologies Announces OTCQB Listing, DTC Eligibility and Leadership Transition

Rzolv Technologies Inc. (TSXV: RZL,OTC:RZOLF) (FSE: S711) (OTCQB: RZOLF) ("RZOLV" or the "Company") is pleased to announce that its common shares have been approved for trading on the OTCQB Venture Market ("OTCQB"), operated by OTC Markets Group Inc., under the trading symbol "RZOLF." The... Keep Reading...

17 February

RZOLV Technologies Announces OTCQB Listing, DTC Eligibility and Leadership Transition

Rzolv Technologies Inc. (TSXV: RZL,OTC:RZOLF) (FSE: S711) (OTCQB: RZOLF) ("RZOLV" or the "Company") is pleased to announce that its common shares have been approved for trading on the OTCQB Venture Market ("OTCQB"), operated by OTC Markets Group Inc., under the trading symbol "RZOLF." The... Keep Reading...

17 February

RZOLV Technologies Announces OTCQB Listing, DTC Eligibility and Leadership Transition

Rzolv Technologies Inc. (TSXV: RZL,OTC:RZOLF) (FSE: S711) (OTCQB: RZOLF) ("RZOLV" or the "Company") is pleased to announce that its common shares have been approved for trading on the OTCQB Venture Market ("OTCQB"), operated by OTC Markets Group Inc., under the trading symbol "RZOLF." The... Keep Reading...

04 February

Charbone Announces its First Hydrogen Supply Hub in the Ontario Market

(TheNewswire) Brossard, Quebec, February 4, 2026 TheNewswire Charbone CORPORATION (TSXV: CH,OTC:CHHYF; OTCQB: CHHYF; FSE: K47) ("Charbone" or the "Company"), a North American producer and distributor specializing in clean Ultra High Purity ("UHP") hydrogen and strategic industrial gases, is... Keep Reading...

04 February

Charbone annonce l'etablissement de son premier pole d'approvisionnement en hydrogene sur le marche Ontarien

(TheNewswire) Brossard, Quebec, le 4 février 2026 TheNewswire - CORPORATION Charbone (TSXV: CH,OTC:CHHYF; OTCQB: CHHYF; FSE: K47) (« Charbone » ou la « Société »), un producteur et distributeur nord-américain spécialisé dans l'hydrogène propre Ultra Haute Pureté (« UHP ») et les gaz industriels... Keep Reading...

02 February

10 Biggest EV Stocks to Watch in 2026

The energy revolution is here to stay, and electric vehicles (EVs) have become part of the mainstream narrative. The shift toward green energy is gathering momentum, with governments adding more incentives to accelerate this transition. Increasing EV sales are good news for battery metals... Keep Reading...

Latest News

Sign up to get your FREE

Provaris Energy Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00