July 10, 2023

Altech Batteries Limited (Altech/the Company) (ASX: ATC and FRA: A3Y) is pleased to announce that the Company has engaged the Centre of International Climate and Environmental Research (CICERO), associated with the University of Oslo, for a green accreditation of the CERENERGY® battery and project.

Highlights

- CICERO engaged to evaluate green credentials of CERENERGY® battery project

- Independent studies cited on Greenhouse Gas Emissions (GHG) for both lithium-ion and CERENERGY® batteries

- Comprehensive analysis performed of the life cycle of both battery types

- CERENERGY® batteries exhibit a minimum 50% lower GHG emissions compared to lithium- ion batteries

- Superior environmental performance and footprint

- CERENERGY® eliminates the need for critical metals such as lithium, cobalt, copper, graphite, and manganese

- ESG reporting program initiated - World Economic Forum ESG Framework

The Company has enlisted the services of CICERO to conduct an external assessment of its environmental credentials. CICERO is renowned for its expertise in providing independent evaluations for green credentials, particularly within the green bond market. Previously, the Company sought CICERO's accreditation for its Silumina AnodesTM project, which received a "Light Green" rating.

With the transition towards renewable energy sources in the global energy sector, the importance of efficient energy storage systems is growing rapidly. Grid storage batteries have emerged as a highly promising solution to address the intermittency and variability associated with renewable energy sources. Altech is well aware of this trend and has strategically focused its efforts on the grid storage battery market, exclusively targeting this sector with its revolutionary Sodium-Chloride Solid State CERENERGY® batteries. Whilst lithium-ion batteries currently dominate the emerging grid storage sector, the following analysis examines the carbon footprint of the CERENERGY® battery in comparison to its competitors.

Greenhouse Gas Emissions (GHG) Footprint

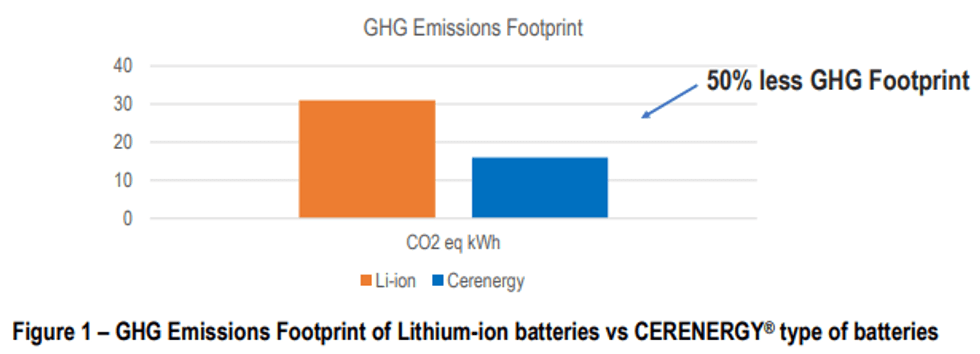

A study titled "Life Cycle Assessment of Sodium-Nickel-Chloride Batteries (CERENERGY® batteries)" conducted by the Sustainable Technologies Laboratory at Bochum University of Applied Sciences in Bochum examines the ecological implications of different battery types, specifically lead acid batteries, lithium-ion batteries, and sodium-chloride CERENERGY® batteries. The study focused on greenhouse gas emissions (GHG) as a key parameter and incorporates two scenarios related to end-of-life (EoL) considerations, including waste management and battery lifespan.

The results indicate that the GHG emissions of CERENERGY® batteries range from 9.1 to 22.7 g CO2eq per kWh (with an average of 16 g CO2eq per kWh) discharged and consumed, compared to 31.3 g CO2eq for lithium-ion batteries and 122.1 g CO2eq for lead-acid batteries. The life cycle assessment concludes that CERENERGY® batteries exhibit a GHG footprint of at least 50% lower than that of lithium-ion batteries. This outcome aligns with the fact that CERENERGY® batteries do not rely on critical metals such as lithium, cobalt, copper, graphite, and manganese, which are associated with high GHG emissions from mining and extraction processes. Instead, CERENERGY® batteries employ sodium-chloride (common table salt) and nickel, of which nickel is also used in lithium-ion batteries. The production of lithium-ion batteries has faced criticism due to its negative environmental impact.

Use of Renewable Power

The planned CERENERGY® battery plant in Saxony, with a capacity of 100 MWh, has been meticulously designed to minimise its greenhouse gas (GHG) footprint by leveraging renewable energy sources. To illustrate, the tunnel kiln utilised for sintering the ceramic tubes will be powered by electricity instead of natural gas, enabling the utilisation of renewable power. In fact, the entire factory will completely abstain from natural gas usage. All heating systems within the plant have been specifically designed for renewable electrical heating. The site's total power requirement is approximately 5 MWh, and negotiations are currently underway to secure a renewable power supply for the facility.

On Site Renewable Generation

The 100 MWh CERENERGY® battery plant has been designed with an expansive factory roof space dedicated to housing photovoltaic panels. These panels harness solar energy during daylight hours, generating renewable power. To optimise energy usage, the plant employs multiple banks of 1 MWh GridPacks to store excess energy during the day for use during nighttime hours. By combining photovoltaic panels with energy storage capabilities, the CERENERGY® battery plant demonstrates a commitment to sustainable practices.

Click here for the full ASX Release

This article includes content from Altech Batteries, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

ATC:AU

Sign up to get your FREE

Altech Batteries Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

The Conversation (0)

11 May 2025

Altech Batteries

Revolutionary sodium-chloride solid state batteries for renewable energy storage and silicon in graphite anodes for higher energy density batteries.

Revolutionary sodium-chloride solid state batteries for renewable energy storage and silicon in graphite anodes for higher energy density batteries. Keep Reading...

27 January

Quarterly Activities/Appendix 5B Cash Flow Report

Altech Batteries (ATC:AU) has announced Quarterly Activities/Appendix 5B Cash Flow ReportDownload the PDF here. Keep Reading...

06 January

Altech - CERENERGY Project Secures German Grant Approval

Altech Batteries (ATC:AU) has announced Altech - CERENERGY Project Secures German Grant ApprovalDownload the PDF here. Keep Reading...

30 November 2025

Altech - Board Renewal and Strategic Focus

Altech Batteries (ATC:AU) has announced Altech - Board Renewal and Strategic FocusDownload the PDF here. Keep Reading...

27 November 2025

Altech - Board and Management Changes

Altech Batteries (ATC:AU) has announced Altech - Board and Management ChangesDownload the PDF here. Keep Reading...

26 November 2025

Altech - Design Completed for UPS Battery System

Altech Batteries (ATC:AU) has announced Altech - Design Completed for UPS Battery SystemDownload the PDF here. Keep Reading...

27 January

Top 5 Canadian Graphite Stocks (Updated January 2026)

Graphite stocks and prices have experienced volatility in recent years recently due to bottlenecks in demand for electric vehicles, as graphite is used to create lithium-ion battery anode materials. One major factor experts are watching is the trade war between China and the US.China introduced... Keep Reading...

09 December 2025

Greenland Government Grants Exploitation Licence for Amitsoq

GreenRoc Strategic Materials Plc (AIM: GROC), a company focused on the development of critical mineral projects in Greenland, is delighted to announce that the Government of Greenland has granted an Exploitation Licence for the Amitsoq Graphite Project to Greenland Graphite a/s ("Greenland... Keep Reading...

27 November 2025

Major JORC Resource & Reserve Upgrade at Orom-Cross

Blencowe Resources Plc (LSE: BRES) is pleased to announce the completion of the updated JORC 2012 Mineral Resource and Ore Reserve Statement ("JORC") for its 100%-owned Orom-Cross Graphite Project in Uganda. This upgrade incorporates all the infill drilling undertaken in 2025 across the Camp... Keep Reading...

06 November 2025

Amitsoq Update - Graphite pilot processing plant

GreenRoc Strategic Materials Plc (AIM: GROC), a company focused on the development of critical mineral projects in Greenland, is pleased to announce that it has signed a purchase agreement with a leading manufacturing company in China for a line of graphite processing mills and has also signed a... Keep Reading...

21 October 2025

Camp Lode Deposit Delivers High-Grade, Near-Surface Graphite

Further results expected imminently from Northern Syncline infill programme

Blencowe Resources Plc (LSE: BRES), the natural resources company advancing the Orom-Cross graphite project in Uganda, is pleased to announce further assay results from its Stage 7 drilling programme at its flagship Orom-Cross graphite project in northern Uganda. The Stage-7 campaign, the... Keep Reading...

Latest News

Sign up to get your FREE

Altech Batteries Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00