February 05, 2024

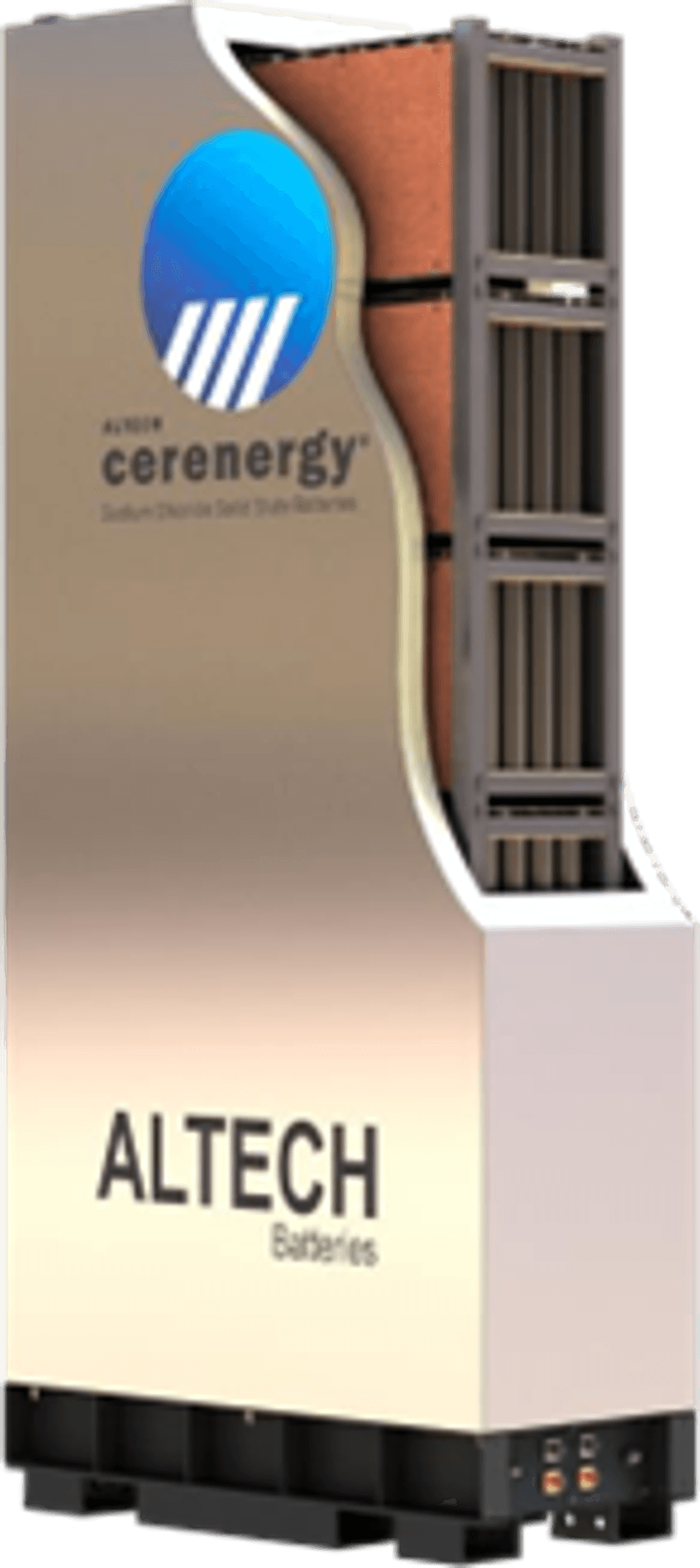

Altech Batteries Limited (Altech/the Company) (ASX: ATC and FRA: A3Y) is providing an update on the advancement of its ABS60 60 kWh CERENERGY® battery prototypes.

Highlights

- Excellent progress with two 60 kWh battery pack prototypes

- Pilot plant re-design at Fraunhofer IKTS Hermsdorf for prototype manufacture

- All prototype materials have been procured from suppliers

- Ceramic tube manufacture is 50% complete

- Cell assembly progressing well with more than half completed

- Low reject and defect rates experienced

- Two battery vacuum casings delivered and undergoing heat loss testing

- Finalisation of prototypes will be mid 2024

The manufacturing of two such batteries dedicated to customer performance testing commenced last year. Altech’s joint venture partner, German government owned Fraunhofer IKTS, had initially developed battery packs with capacities of 5 kWh and 10 kWh units. However, with the establishment of the joint venture with Altech, a significant upgrade was undertaken, resulting in the transformation of the battery pack into a substantial 60 kWh unit specifically designed for the grid storage market. Production of two of these substantial 60 kWh battery packs was initiated for the purpose of conducting performance tests and qualifying them for customer use.

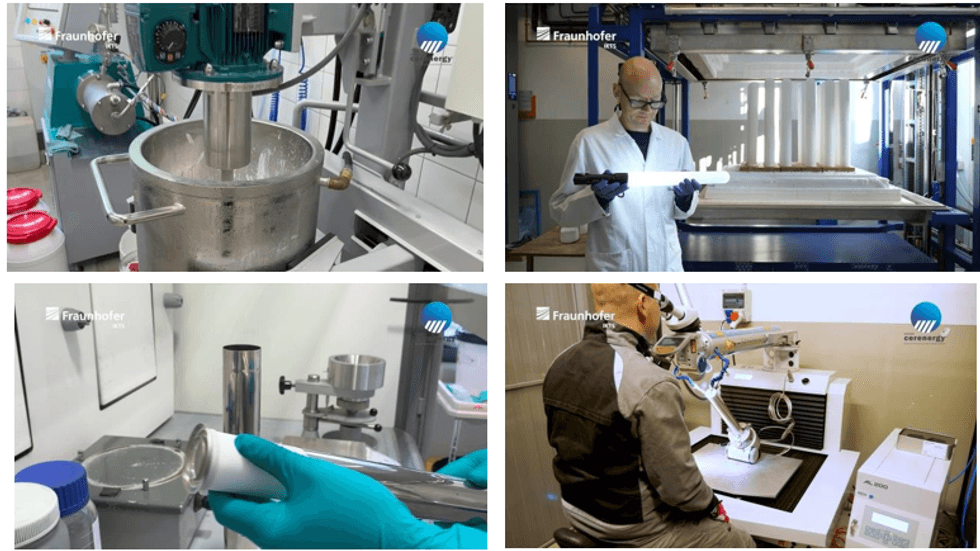

The pilot line at Fraunhofer IKTS, situated in Hermsdorf, Germany, has undergone a comprehensive redesign to facilitate the manufacturing of 60 kWh battery prototypes. Innovative tools and machinery have been developed and implemented specifically for producing the battery cells required for the 60 kWh prototypes. The battery pack is composed of 240 CERENERGY® cells, each rated at 2.5 V. These cells are organised in 4 rows, each comprising 12 cells, and stacked 5 modules high. The dimensional specifications of the battery packs are 2.6 meters in height, 0.4 meters in length, and 1.0 meter in width. Ensuring adherence to the Ingress Protection (IP) 65 standard, the packs are designed to be dust and weatherproof, reflecting high levels of sealing effectiveness for electrical enclosures.

All prototype materials have now been procured from specific suppliers. The crucial stages in cell production involve blending ceramic components, high-pressure pressing, tube formation, and ultimately sintering at 1,600 degrees celsius over a span of several days. Fraunhofer IKTS’ Hermsdorf pilot plant facility successfully navigated the entire ceramic tube production, with half of the required tubes now manufactured. The battery cathode electrolyte, comprising sodium chloride and nickel powder granules, was produced using the mixing and pelletising equipment at the Hermsdorf pilot plant. The process of cell assembly, encompassing vacuum filling, heating, and welding, is ongoing, resulting in the completion of approximately half of the cells. To facilitate the infiltration of cathode material into multiple battery cells simultaneously, a vacuum chamber was developed. Promising pass results were obtained from laser welding tests on the battery cells conducted at Precitec GmbH & Co. KG

In order to confirm the precise alignment of all components following the welding closure of each prototype cell, a thorough examination is conducted using an industrial micro computed tomography (µCT) scanning system. This ensures the verification of filling height, composition, alignment, and the behavior of cathode material post cell initialisation. Upon successful completion of the µCT quality assurance, individual cells undergo charge and discharge performance tests, all of which have demonstrated satisfactory and as expected results thus far. As of now, fifty percent of the necessary cells have been successfully produced, showcasing excellent progress. Reject or defect rates have been low and with expected limits.

Click here for the full ASX Release

This article includes content from Altech Batteries, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

ATC:AU

Sign up to get your FREE

Altech Batteries Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

The Conversation (0)

11 May 2025

Altech Batteries

Revolutionary sodium-chloride solid state batteries for renewable energy storage and silicon in graphite anodes for higher energy density batteries.

Revolutionary sodium-chloride solid state batteries for renewable energy storage and silicon in graphite anodes for higher energy density batteries. Keep Reading...

27 January

Quarterly Activities/Appendix 5B Cash Flow Report

Altech Batteries (ATC:AU) has announced Quarterly Activities/Appendix 5B Cash Flow ReportDownload the PDF here. Keep Reading...

06 January

Altech - CERENERGY Project Secures German Grant Approval

Altech Batteries (ATC:AU) has announced Altech - CERENERGY Project Secures German Grant ApprovalDownload the PDF here. Keep Reading...

30 November 2025

Altech - Board Renewal and Strategic Focus

Altech Batteries (ATC:AU) has announced Altech - Board Renewal and Strategic FocusDownload the PDF here. Keep Reading...

27 November 2025

Altech - Board and Management Changes

Altech Batteries (ATC:AU) has announced Altech - Board and Management ChangesDownload the PDF here. Keep Reading...

26 November 2025

Altech - Design Completed for UPS Battery System

Altech Batteries (ATC:AU) has announced Altech - Design Completed for UPS Battery SystemDownload the PDF here. Keep Reading...

18 February

US Slaps Higher Tariffs on Chinese Graphite Imports After Final Commerce Determination

The US Department of Commerce has sharply increased trade penalties on Chinese graphite anode materials, concluding that producers in China engaged in unfair pricing and subsidy practices that harmed the US market.In a final determination issued February 11, 2026, Commerce raised countervailing... Keep Reading...

27 January

Top 5 Canadian Graphite Stocks (Updated January 2026)

Graphite stocks and prices have experienced volatility in recent years recently due to bottlenecks in demand for electric vehicles, as graphite is used to create lithium-ion battery anode materials. One major factor experts are watching is the trade war between China and the US.China introduced... Keep Reading...

09 December 2025

Greenland Government Grants Exploitation Licence for Amitsoq

GreenRoc Strategic Materials Plc (AIM: GROC), a company focused on the development of critical mineral projects in Greenland, is delighted to announce that the Government of Greenland has granted an Exploitation Licence for the Amitsoq Graphite Project to Greenland Graphite a/s ("Greenland... Keep Reading...

27 November 2025

Major JORC Resource & Reserve Upgrade at Orom-Cross

Blencowe Resources Plc (LSE: BRES) is pleased to announce the completion of the updated JORC 2012 Mineral Resource and Ore Reserve Statement ("JORC") for its 100%-owned Orom-Cross Graphite Project in Uganda. This upgrade incorporates all the infill drilling undertaken in 2025 across the Camp... Keep Reading...

06 November 2025

Amitsoq Update - Graphite pilot processing plant

GreenRoc Strategic Materials Plc (AIM: GROC), a company focused on the development of critical mineral projects in Greenland, is pleased to announce that it has signed a purchase agreement with a leading manufacturing company in China for a line of graphite processing mills and has also signed a... Keep Reading...

Latest News

Sign up to get your FREE

Altech Batteries Investor Kit

and hear about exciting investment opportunities.

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00