FPX Nickel Corp. (TSXV: FPX), (OTCQB: FPOCF) (" FPX " or the " Company ") is pleased to announce that it has successfully completed another large-scale mineral processing pilot testing campaign for the Baptiste Nickel Project (" Baptiste " or the " Project "). Building on the success of three previous pilot testing campaigns, a production run was completed to produce bulk samples of awaruite concentrate which will be used to verify the suitability of using this concentrate as a feedstock in third-party nickel refineries. Samples will be provided to selected prospective downstream partners — most notably pCAM producers, battery companies, and automakers — who typically secure nickel units directly and contract refiners to process feedstocks on their behalf. This reflects an established industry model, supporting end users' pursuit of supply security, traceable sourcing, and low-carbon production.

"The ability to process awaruite concentrate through existing nickel refineries provides us with greater strategic flexibility, in addition to its potential use directly in stainless steel or as feedstock for the development of a new integrated refinery to produce battery-grade nickel sulphate," commented Martin Turenne , FPX Nickel's President and Director. "This flexibility strengthens our position in strategic discussions with automakers, battery companies, and other downstream partners, and places awaruite alongside established high-grade nickel intermediates such as MHP and matte as a disruptive new source of nickel for the EV supply chain."

Figure 1 – Samples of Awaruite Concentrate Produced from Baptiste's Production Run Pilot Plant

Background

The Baptiste processing strategy leverages awaruite's distinct properties in a simple, yet robust flowsheet. The front-end of the flowsheet utilizes magnetic separation to create a "magnetics-rich" concentrate of awaruite and magnetite – a process made effective due to awaruite's intense ferromagnetism and high density. The back-end of the flowsheet then utilizes conventional froth flotation to separate awaruite from magnetite – a process made effective due to awaruite's active surface properties and magnetite's general lack of floatability. Finally, based on awaruite's very high nickel content, a very high-grade nickel concentrate (60% nickel) can be produced.

Downstream of the mineral processing plant, awaruite's properties continue to provide distinct advantages, including unparalleled downstream market flexibility. Unlike conventional nickel concentrates, which typically have high sulphur content, Baptiste's awaruite concentrate is nearly sulphur-free and low in deleterious elements, allowing it to bypass smelting and be used directly in stainless steel fabrication. Alternatively, the Baptiste awaruite concentrate is also an ideal feedstock for the production of high-purity, battery-grade nickel sulphate for the electric vehicle (" EV ") supply chain.

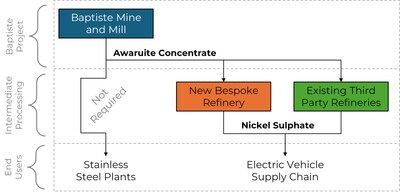

Figure 2 – Potential Product Integration Routes for the Baptiste Awaruite Concentrate

Integration of the Baptiste awaruite concentrate into the EV supply chain can be achieved through two routes as shown in Figure 2. The first integration route is through the construction of a bespoke integrated hydrometallurgical refinery to produce battery-grade nickel sulphate from Baptiste concentrate. The Company has recently demonstrated the technical and economic viability of this (as described in the FPX's March 31st, 2025 news release) and has recently completed a production run of nickel sulphate (as described in the FPX's June 17th, 2025 news release) to provide samples to selected prospective downstream partners.

A second integration route is for the Baptiste awaruite concentrate to be refined in an existing third-party nickel refinery. Although nickel refineries are generally sensitive to variations in feedstocks, awaruite concentrate can be used to supplement a portion of the feedstock, particularly for nickel refineries designed to treat both mixed hydroxide precipitate (" MHP ") and nickel matte — the two most commonly interchangeable nickel intermediates. Awaruite concentrate has properties that position it between MHP and matte — with fewer impurities than MHP but more than matte, and requiring less aggressive leaching than matte but more than MHP — making it broadly comparable to both and a credible feedstock for nickel refineries. The production of bulk quantities of awaruite concentrate will enable this strategy to be validated by prospective downstream partners through direct testing of awaruite concentrate.

In addition to supplying refiners directly, awaruite concentrate can also be marketed to end users such as pCAM producers, battery companies, and automakers. Under this established industry model, end users purchase and hold the nickel units while established third-party refiners perform the conversion to nickel sulphate under tolling arrangements. This dual-path approach provides flexibility in commercialization while reinforcing awaruite's compatibility with existing refining infrastructure.

Pilot Plant

The Company re-engaged Corem ( Quebec, Canada ) to operate the pilot plant, building on their experience conducting two previous successful piloting programs for FPX. A total of 23 tonnes of material were processed, resulting in approximately 2.2 days of continuous run-time at an average rate of 430 kg/h in the primary grinding and magnetic separation circuits. Using the optimized flowsheet developed in the prior campaign (as described in FPX's April 30, 2024 news release), this more recent campaign achieved the targeted recoveries, concentrate nickel grade and impurity levels, consistent with expectations and further demonstrates the reliability of the Baptiste process. Figure 1 shows the first batch of concentrate produced from this campaign while Table 1 shows the concentrate composition.

Table 1 – Awaruite Concentrate Composition

| Element | Nickel | Cobalt | Iron | Sulphur | Magnesium | Copper |

| Grade (%) | 64 | 1.1 | 26 | 0.3 | 1.6 | 0.4 |

Qualified Person

The metallurgical information in this news release has been prepared in accordance with Canadian regulatory requirements set out in National Instrument 43-101: Standards of Disclosures for Minerals Projects of the Canadian Securities Administrators (" NI 43-101 "). Testwork was supervised, reviewed, and verified by Kyle D. Marte , P.Eng., FPX Nickel's Director of Metallurgy and a "Qualified Person" as defined by NI 43-101.

About the Baptiste Nickel Project

The Company's Baptiste Nickel Project represents a large-scale greenfield discovery of nickel mineralization in the form of a sulphur-free, nickel-iron mineral called awaruite (Ni 3 Fe) hosted in an ultramafic/ophiolite complex. The absence of sulphur and our ability to connect to the BC Hydro grid means that Baptiste has the potential to be one of the lowest carbon-intensive nickel producers in the world and will produce a very high-grade product that does not require any intermediate smelting or complex refining. The Baptiste mineral claims cover an area of 453 km 2 west of Middle River and north of Trembleur Lake, in central British Columbia. In addition to the Baptiste Deposit itself, awaruite mineralization has been confirmed through drilling at several target areas within the same claims package, most notably at the Van Target which is located 6 km to the north of the Baptiste Deposit. Since 2010, approximately US$55 million has been spent on the exploration and development of Baptiste.

FPX has conducted mineral exploration activities to date subject to the conditions of agreements with First Nations and keyoh holders. In 2024, the Province of British Columbia identified the Baptiste Nickel Project as the first project to be included in the Province's new Critical Minerals Office ( "CMO" ) concierge service initiative, a provincial strategy action to enable the prioritization of critical minerals projects in B.C. The CMO initiative is providing an excellent structure to proactively identify and address issues and opportunities ahead of the Project's entry into the environmental assessment process.

About FPX Nickel Corp.

FPX Nickel Corp. is focused on the exploration and development of the Decar Nickel District, located in central British Columbia , and other occurrences of the same unique style of naturally occurring nickel-iron alloy mineralization known as awaruite. For more information, please view the Company's website at https://fpxnickel.com/ .

On behalf of FPX Nickel Corp.

"Martin Turenne"

Martin Turenne , President, CEO and Director

Forward-Looking Statements

Certain of the statements made and information contained herein is considered "forward-looking information" within the meaning of applicable Canadian securities laws. These statements address future events and conditions and so involve inherent risks and uncertainties, as disclosed in the Company's periodic filings with Canadian securities regulators. Actual results could differ from those currently projected. The Company does not assume the obligation to update any forward-looking statement.

Neither the TSX Venture Exchange nor its Regulation Services Provider accepts responsibility for the adequacy or accuracy of this release.

SOURCE FPX Nickel Corp.

![]() View original content to download multimedia: http://www.newswire.ca/en/releases/archive/September2025/04/c5612.html

View original content to download multimedia: http://www.newswire.ca/en/releases/archive/September2025/04/c5612.html