Altiplano Metals Inc. (TSXV: APN) (WKN: A2JNFG) ("Altiplano" or the "Company") is pleased to provide an update on the construction phase at the El Peñón processing facility to support the Farellon Iron-Oxide-Copper-Gold (Cu-Au) mine located near La Serena, Chile.

The Company is pleased to report the application to incorporate an iron separator (designed to recover high value iron oxide) and a high efficiency water recovery circuit (designed to produce dry tailings), has been approved by the Chilean mining authority. Addition of this equipment into the processing circuit provides the opportunity to capture high value iron which can be sold to generate a secondary income and, with the removal of the iron, reduce the overall tailings output by 50%. The dewatering stack will generate a dry tailings product that can be moved and stored in an environmentally efficient manner which replaces the need for a conventional tailings dam system. In addition, the de-watering stack circuit will reduce the overall freshwater consumption needed at the plant by approximately 75%. The equipment has been newly manufactured and will be delivered from storage in Chile to the site next week. Civil work such as pad levelling, electrical, and plumbing is underway in preparation to install the equipment.

CEO Alastair McIntyre comments "We are pleased to receive this important approval as the next step in completing our processing facility. With our processing design, APN will be one of the first companies in the Chilean small mining sector to implement an industry-leading environmental process focussed on water conservation and waste reduction. Water is an important resource in Chile and our process is designed to preserve this precious resource. I believe our best practice approach to sustainable mining and environmentally friendly processing will minimize our footprint and establish APN as a leader in the Chilean small mining sector."

Plant Description

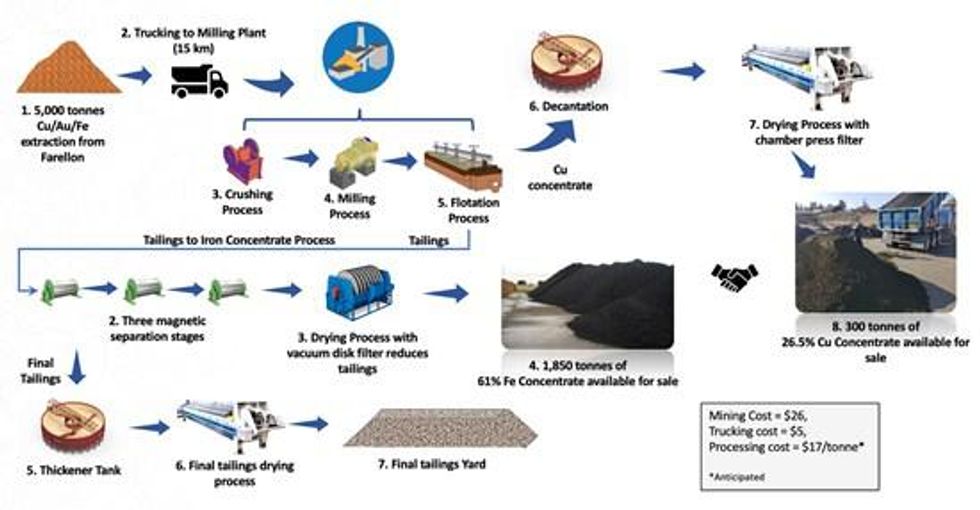

The APN processing facility will employ modern high efficiency flotation circuits that focus on the recovery of copper and gold while also utilizing a magnetic separation system for the recovery of magnetite and other iron minerals (Figure 1). The circuit will use a filter press system for copper concentrate and tails and a disc filter for the iron concentrate. All systems are designed to focus on water conservation and reducing total tails output. The combined process is designed to reduce the total material reporting to tailings by up to 50%, compared to the standard practice of copper processing plants treating iron oxide copper gold (IOCG) deposits. Water will be recovered and recycled thus ensuring water is reused efficiently, with an expected reduction in freshwater consumption by approximately 75% over conventional systems. Typically, standard plant configurations for small mining are limited to recovery by flotation without efficient water recovery systems. In addition, moisture content in the tailings will be reduced to approximately 10% to 15% through the filter press system and placed in a dry stack tailings facility. This additional process will significantly reduce water loss to evaporation compared to conventional tailings dam. The processing facilty completion date is scheduled for Q1 2022.

Figure 1. Processing Plant Flow Sheet.

To view an enhanced version of Figure 1, please visit:

https://orders.newsfilecorp.com/files/4303/107781_a836b1cff4e9c8c9_001full.jpg

In addition to the conservation of water, magnetic separation can recover up to half of the plant feed as a saleable iron concentrate. A total of 1,850 tonnes of iron oxide is expected to be recovered per month and can represent a significant portion of revenue combined with the sale of the copper-gold concentrate.

The circuit takes advantage of magnetic properties of the iron mineralization in the mill feed and does not require additional grinding or dewatering as the feed to magnetic separators is tailings or rejects of the flotation circuit. This process greatly reduces the quantity of tailings that needs disposal in a tailings storage facility while maximizing the recovery of all minerals in mill feed, thus reducing the overall environmental footprint of the mining process.

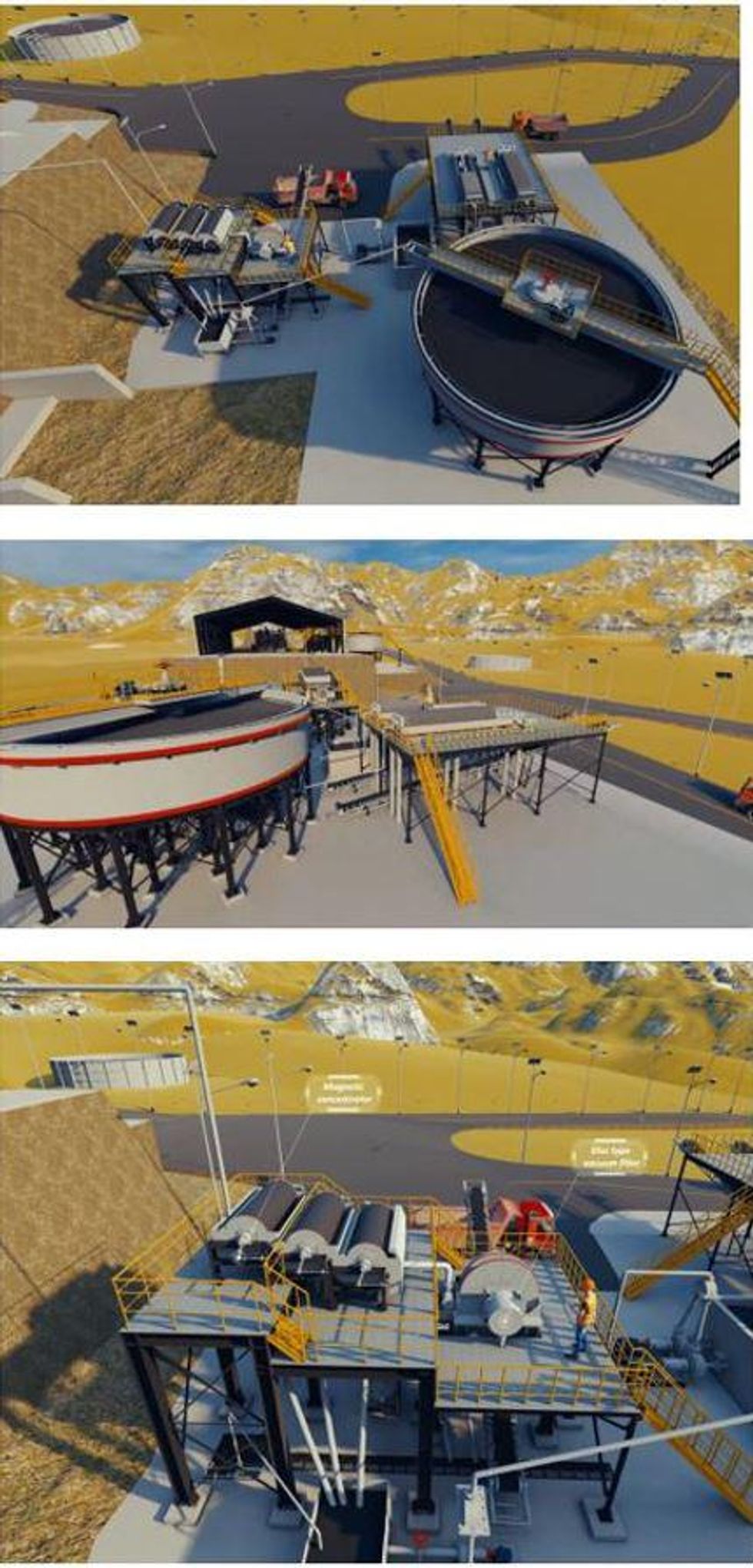

Figure 2. Schematic Illustration of the Magnetic and Drying Facilities.

If you cannot view Figure 2 above, please visit:

https://orders.newsfilecorp.com/files/4303/107781_rfigure2.jpg

A schematic video illustration of the mill operation can be viewed through the following link:

https://www.youtube.com/watch?v=CtbQcP0zqUs

Altiplano has generated greater than US$7.2 million from the recovery and sale of approximately 3.6 million pounds of copper with an average grade of 1.74% Cu (2018 Q1-2021 Q3). Cash flow has been re-invested into equipment, underground drilling, expanding underground development, enhancing ventilation to increase productivity and capacity, and the commencement of the permitted El Peñón fit-for-purpose mill and flotation plant located 15 km from the Farellon site.

About Altiplano

Altiplano Metals is a growing gold, silver, and copper company focused on the Americas. The Company has a diversified portfolio of assets that include an operating copper-gold-iron mine, development near term producing gold-copper projects, and exploration land packages with district-scale potential. Altiplano is focused on creating long-term stakeholder value through developing safe and sustainable production, reinvesting into exploration, and pursuing acquisition opportunities to complement its existing portfolio. Management has a substantial record of success in capitalizing on opportunity, overcoming challenges and building shareholder value. Altiplano trades on the Toronto Venture Exchange trading under the symbol APN and the Frankfurt Exchange under the symbol A2JNFG.

John Williamson, B.Sc., P.Geol., a Qualified Person as defined by NI 43-101, has reviewed, and approved the technical contents of this document.

Altiplano is part of the Metals Group of companies, managed by an award-winning team of professionals who stand for technical excellence, painstaking project selection and uncompromising corporate governance, with a proven ability to capitalize on investment opportunities and deliver shareholder returns.

ON BEHALF OF THE BOARD

/s/ "John Williamson"

Chairman

For further information, please contact:

Alastair McIntyre, President and CEO.

alastairm@apnmetals.com

Tel: (416) 434-3799

Jeremy Yaseniuk, Director

jeremyy@apnmetals.com

Tel: (604) 773-1467

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the (TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This release includes certain statements that may be deemed "forward-looking statements". All statements in this release, other than statements of historical facts, that address exploration drilling, exploitation activities and events or developments that the Company expects are forward-looking statements. A qualified person has not done sufficient work to classify any historical estimates as current mineral resources or mineral reserves and the issuer is not treating the historical estimates as current mineral resources or mineral reserves. The Farellon mine was previously in production dating back to the 1970's with a reported historical production (to a depth of 70 m) yielding approximately 300,000 tonnes at an average grade of 2.5% copper and 0.5g/t gold. This material was processed locally and sold to ENAMI. Altiplano is relying upon past production records, underground sampling and related activities and current diamond drilling to estimate grade and widths of the mineralization to reactivate production. The decision to commence production on the Farellon deposit is not based on a feasibility study of mineral reserves demonstrating economic and technical viability and there is increased uncertainty and economic and technical risks of failure associated with any production decision. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the forward-looking statements. Factors that could cause actual results to differ materially from those in forward-looking statements include market prices, exploitation and exploration successes, continuity of mineralization, uncertainties related to the ability to obtain necessary permits, licenses and title and delays due to third party opposition, changes in government policies regarding mining and natural resource exploration and exploitation, and continued availability of capital and financing, and general economic, market or business conditions. Investors are cautioned that any such statements are not guarantees of future performance and actual results or developments may differ materially from those projected in the forward-looking statements. For more information on the Company, investors should review the Company's continuous disclosure filings that are available at www.sedar.com.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/107781