January 23, 2024

Surefire Resources NL (“Surefire” or “the Company”) is pleased to announce it has achieved a breakthrough process of extracting Vanadium directly from magnetite concentrate out of its 100% owned flagship Victory Bore Vanadium project in Western Australia.

Key Points:

- Laboratory test work has developed a breakthrough pre-treatment and leach process achieving a remarkable extraction of 91% of vanadium and 88% of titanium directly from Victory Bore magnetite concentrate.

- This new metallurgical application alleviates the requirement for standard pre- treatment processes currently used in the vanadium extraction industry.

- The process is expected to be more environmentally acceptable with low emissions and reduced carbon footprint.

- This process will be applied to Surefire’s planned development of its Victory Bore Project and the impact on capital cost and operating cost benefits will be assessed.

- The process will be protected by a provisional patent application, wholly owned by Surefire.

The test work process achieved a remarkable extraction for Vanadium of 91% after a 96-hour leach directly from magnetite concentrate. Additionally, an unexpected extraction of 88% Titanium was also recovered. The leach process was applied to pre-treated concentrate allowing the leach process to effectively scavenge vanadium. This pre-leach treatment is Surefire’s Intellectual Property.

In May 2023 the Company appointed METS Engineering (“METS”) to undertake an assessment of potential for recovery of a high purity vanadium oxide in liquid form, from which a clean high purity vanadium electrolyte could be produced for use in the emerging vanadium battery sector in Australasia, (see ASX announcement 1 May 2023).

Following a detailed literature search and a review of all existing extraction processes, a direct leaching test work programme was designed and established by the METS team. Supervision and reporting was carried out under the direction of METS and all test work undertaken at Western Australian laboratories.

A total of 4 separate hydro-chemical tests were carried out on pre-treated magnetite concentrate (“PTMC”). The successful process is an adaptation of several commercially scalable processes used within the mineral resource industry and involves leaching under certain conditions of the PTMC.

Laboratory testwork involved batches of PTMC from the Victory Bore deposit subjected to 4 separate leachants with catalysts, under various novel conditions.

The total process is a combination of the proprietary PTMC, leachant and novel conditions. The process details are commercial in confidence and remain the IP of Surefire Resources and subject to a Provisional Patent protection.

Sample

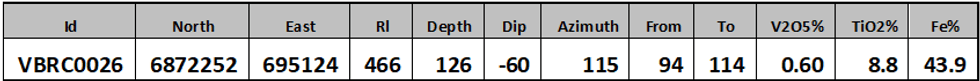

A 500 Kilogram (Kg) composite sample was made up from 20 x 1m Reverse Circulation samples selected from drill hole VBRC026.

Drill hole VBRC026 was selected as it is located in the centre of the Victory Bore deposit, see Figure 4.

Sample Preparation

The samples were prepared using standard beneficiation processes to produce a clean magnetic concentrate for characterisation and laboratory testwork. In February 2023 the company carried out a petrographic study which showed that the Victory Bore magnetite contains most of the vanadium and hosts relatively clean intrinsic vanadium which should enable a simpler and cleaner separation in processing (see ASX announcement 13 February 2023).

Approximately 500 kg of a composite feed sample was stage crushed and rotary split for the characterisation, pre-treatment and testwork. 250kg was used for the testwork with the remaining composite material (of approximately 250 kg) stored as reserve for further work.

Head Assay

A full assay suite was requested for the head assay on the composite feed sample: SiO2, Al2O3, V2O5, TiO2, CaO, MgO, MnO, K2O, Na2O, Cr2O3, Fe, P, S, Ag, Al, B, Ba, Be, Ca, Ce, Cd, Co, Cr, Cu, Ga, Ge, Hf, ln, K, Li, La, Mg, Mn, Mo, Na, Nb, Ni, Pb, Pd, Pt, Rb, Sb, Sc, Si, Sr, Ti, Th, Tl, V, W, Zn, Zr and LOI.

Particle Size Distribution and Size by Assay

The particle size distribution of the composite feed material was analysed for different particle size fractions: +3.35 mm, 2.36 mm, +1 mm, +0.5 mm, +0.15 mm, and +0.075 mm. A size by assay was conducted for each particle size fraction to determine the distribution of key minerals and elements found in each particle size fraction.

Bulk Medium Intensity Magnetic Separation (MIMS)

Wet MIMS was carried out on 250 kg of the composite sample. The recovered mags from the MIMS were ground and then passed through Sighter and Bulk LIMS.

Low Intensity Magnetic Separation (LIMS)

Sighter LIMS was conducted at three different gauss intensities 2000, 1200 and 900 to determine the optimum gauss to run the Bulk LIMS.

Click here for the full ASX Release

This article includes content from Surefire Resources NL, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

The Conversation (0)

21 January

Vanadium Market Forecast: Top Trends for Vanadium in 2026

The vanadium market remained subdued in H1 2025, weighed down by persistent oversupply and weak usage from the steelmaking sector, even as new demand avenues like energy storage gained attention.Price data shows that vanadium pentoxide in major regions such as the US, China and Europe traded in... Keep Reading...

20 January

Carbon Black Substitute Memorandum of Understanding

Ferro-Alloy Resources Limited (LSE:FAR), the vanadium producer and developer of the large Balasausqandiq vanadium deposit in Southern Kazakhstan, is pleased to announce that it has entered into a non-binding, non-exclusive, memorandum of understanding ("MOU") for the supply of up to 360,000... Keep Reading...

25 July 2025

Top 5 Australian Mining Stocks This Week: Vanadium Resources Soars on DSO Offtake Deal

Welcome to the Investing News Network's weekly round-up of Australia’s top-performing mining stocks on the ASX, starting with news in Australia's resource sector.This week, gold companies continued to shine in Australia, joined by battery and base metals explorers and developers. In corporate... Keep Reading...

02 July 2025

QEM Appoints Robert Cooper as Director, following Leadership Transition

Critical minerals and energy company QEM Limited (ASX: QEM) is pleased to announce completion of the previously announced Leadership Transition (refer ASX Announcement 29 May 2025). Highlights: Seasoned global mining executive Robert Cooper has completed a comprehensive handover and is appointed... Keep Reading...

Latest News

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00