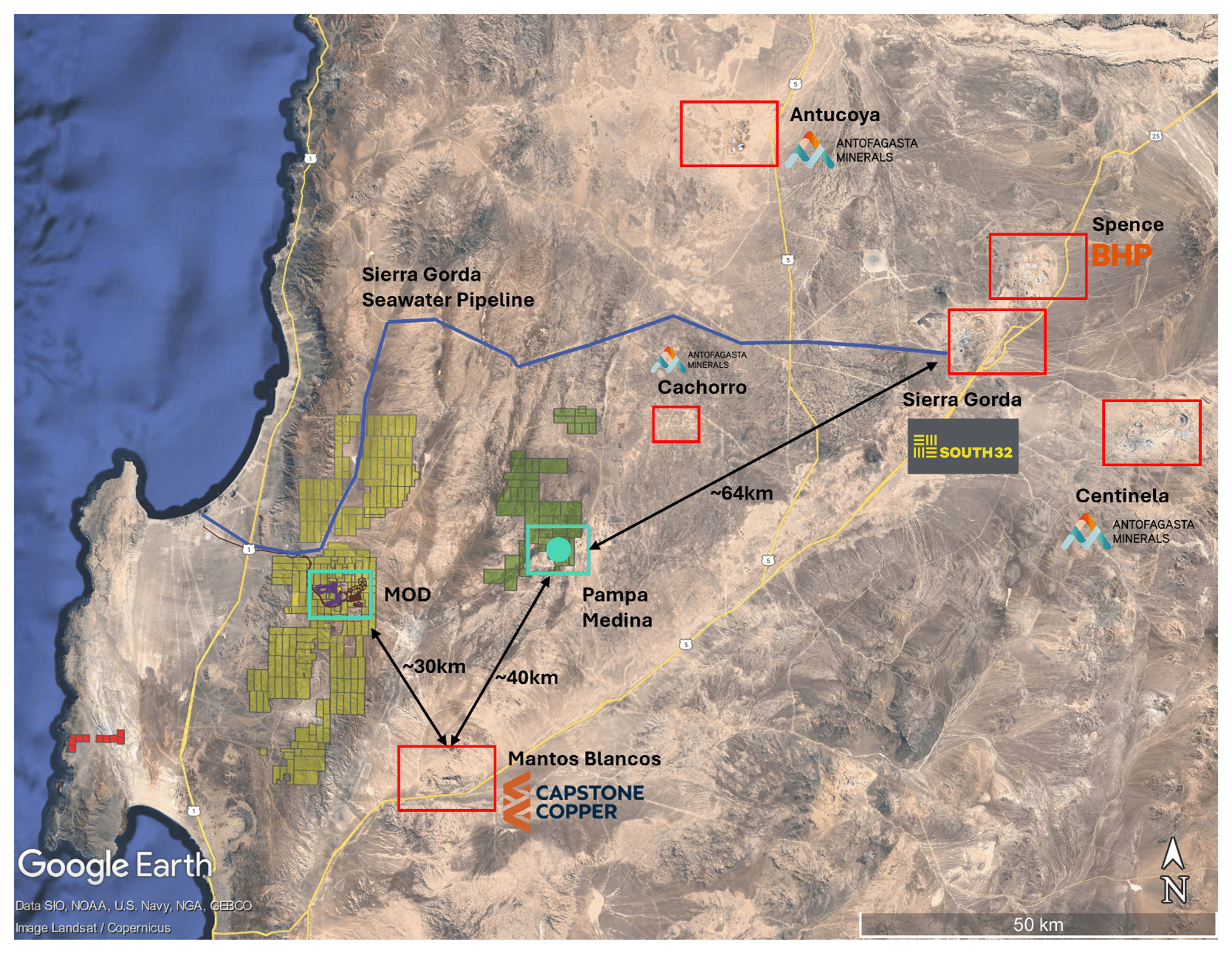

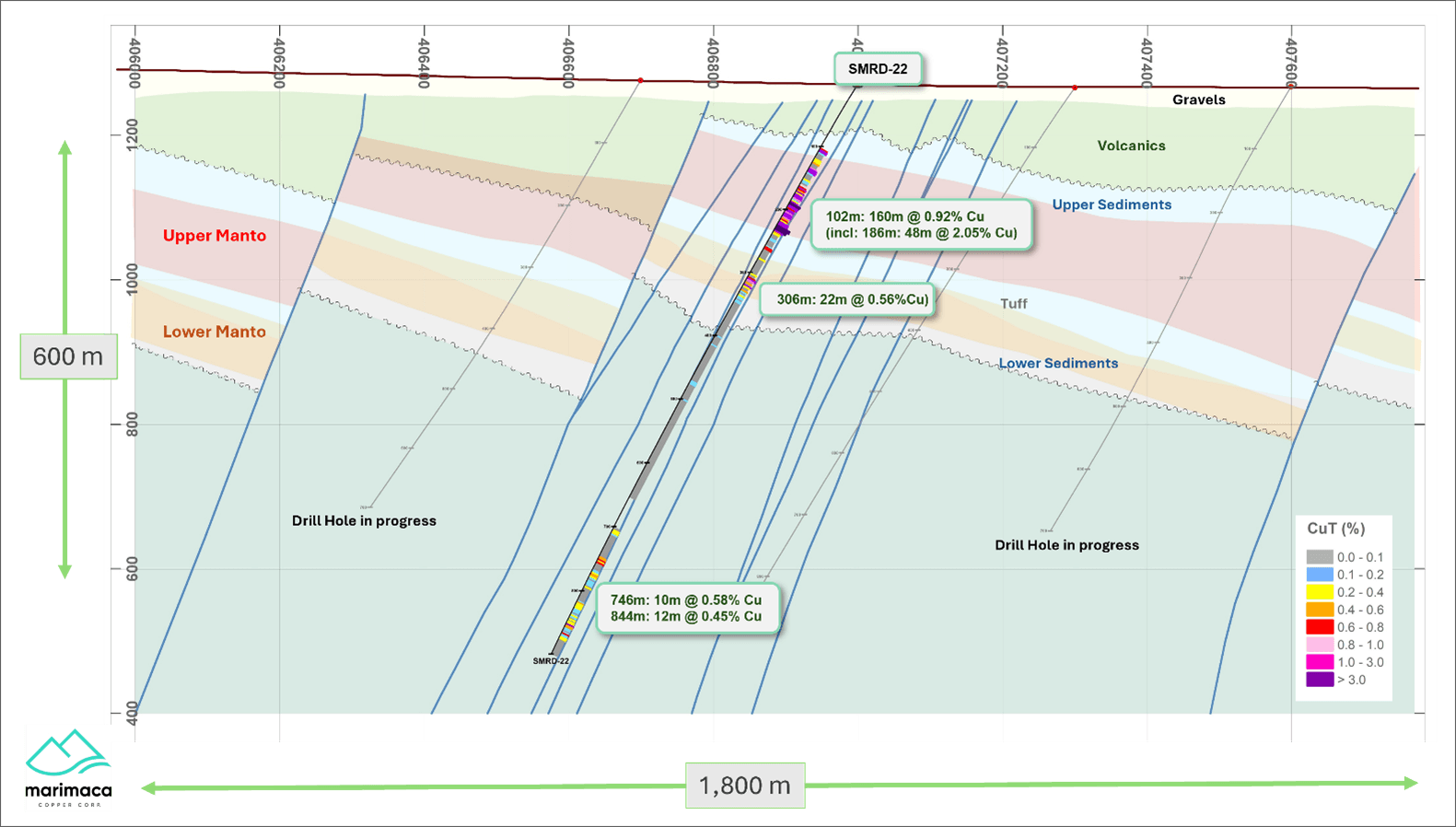

Marimaca Copper Corp. ("Marimaca Copper" or the "Company") (TSX:MARI,OTC:MARIF, ASX:MC2) is pleased to announce the final results from it's 10,000m discovery drilling campaign at the Pampa Medina deposit, located at low altitude approximately 28km east of the Company's Marimaca Oxide Deposit (" MOD ") in a flat "pampa" valley within the Atacama Desert (Figure 1). The drilling results continue to demonstrate material extensions to the high-grade sedimentary-hosted sulphide copper horizon, as well as upside to the known extent of the near-surface oxide mineralization. The Company has subsequently commenced a 30,000m follow-up Phase II drilling program with five drilling rigs currently on site.

Highlights

- Central Pampa Medina drilling continues to improve confidence in high grade oxides and sulphides

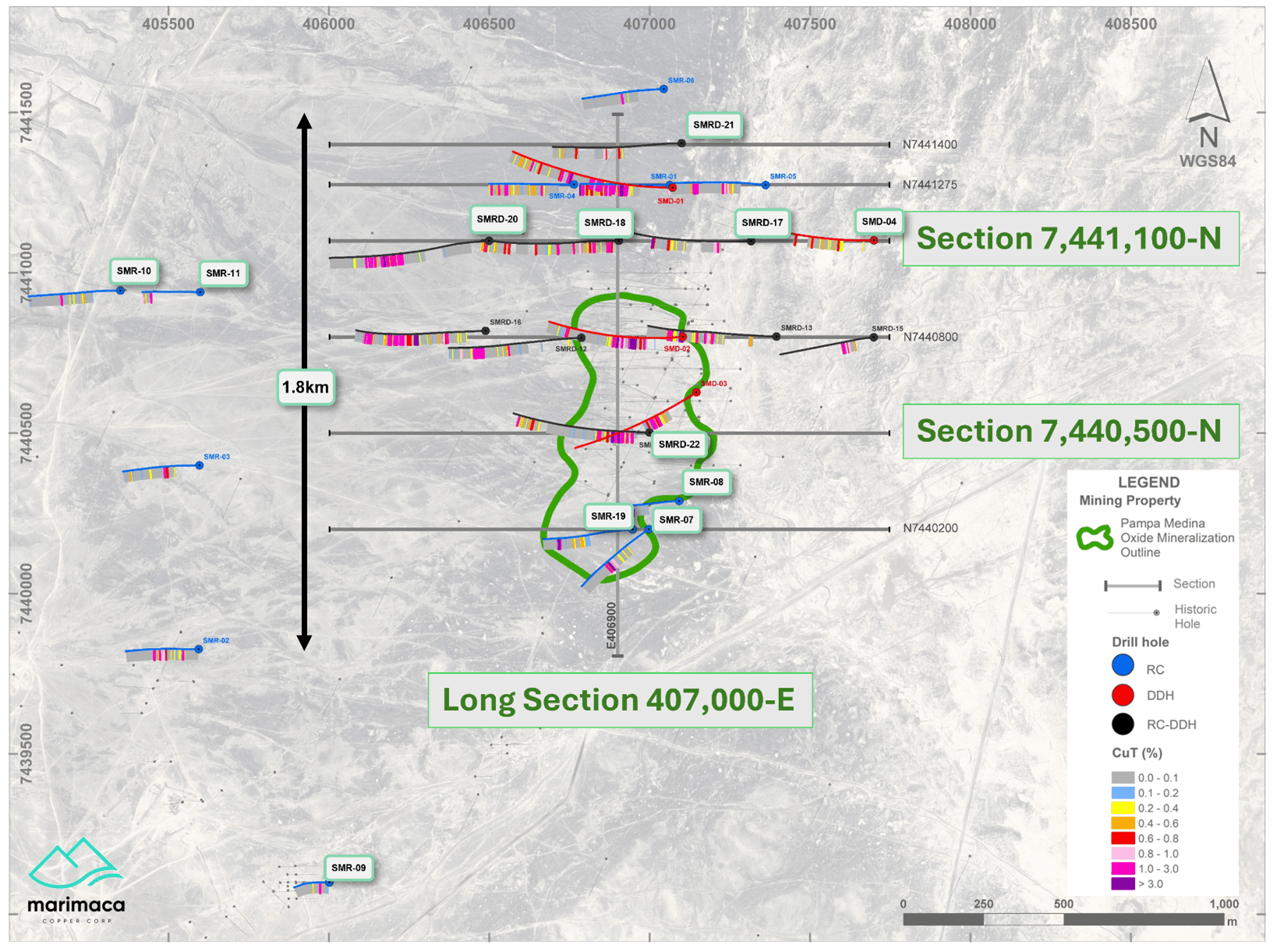

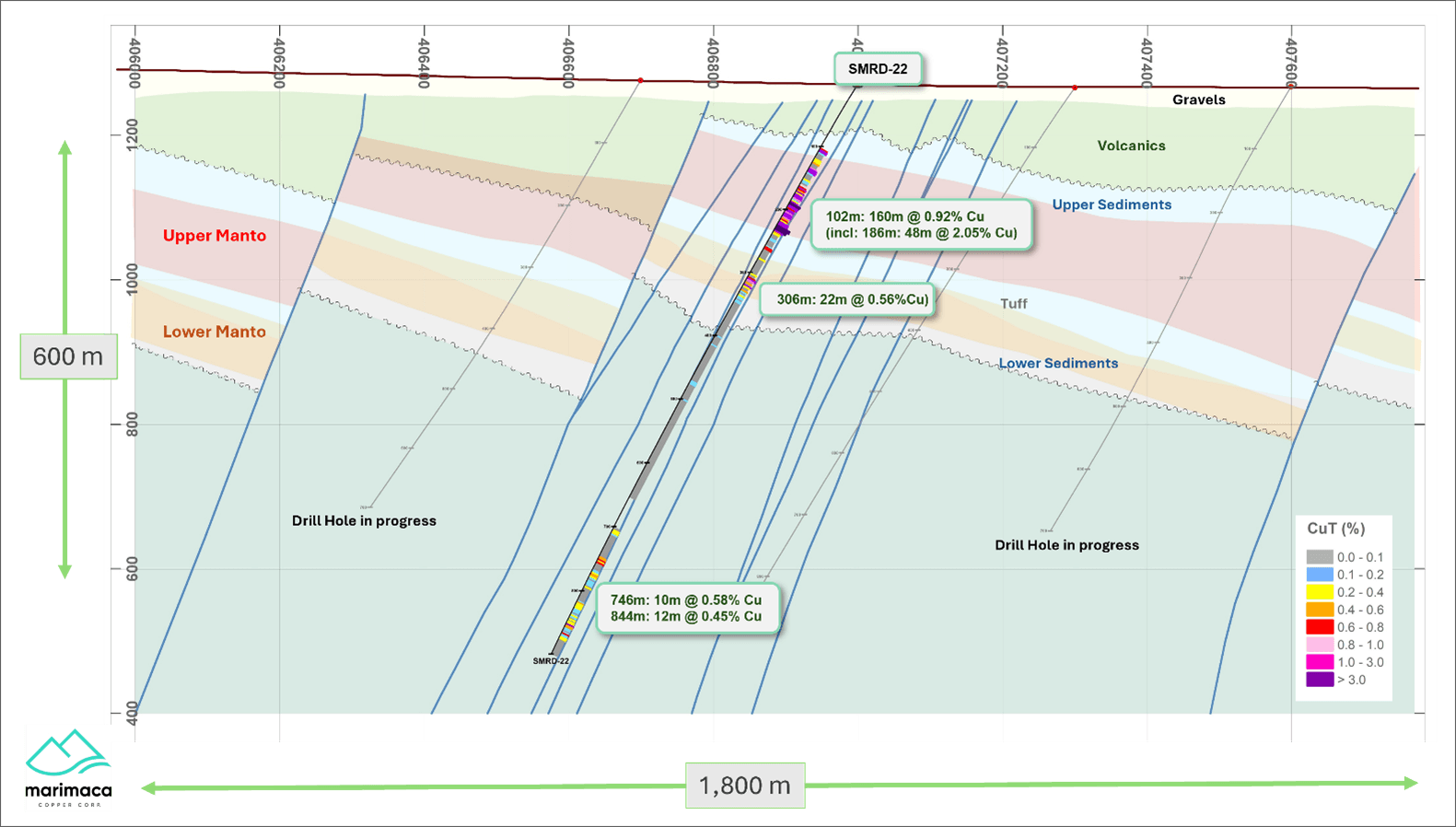

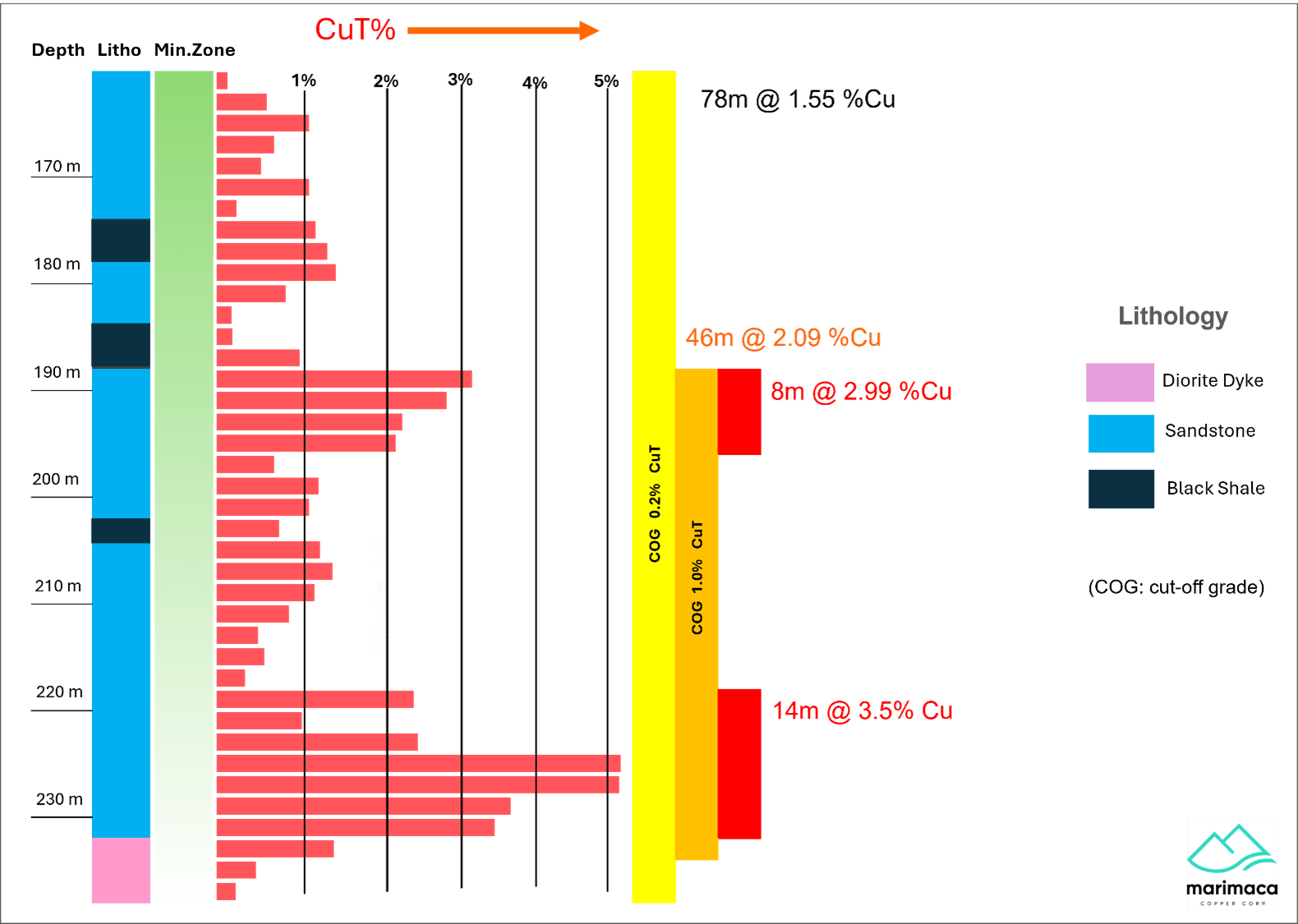

- SMRD-22 intersected 48m of 2.05% Cu from 186m, within 160m of 0.92% Cu from 102m (oxides)

- Southern Pampa Medina drilling confirms primary mineralized sedimentary horizon extends 900m south of previous drilling

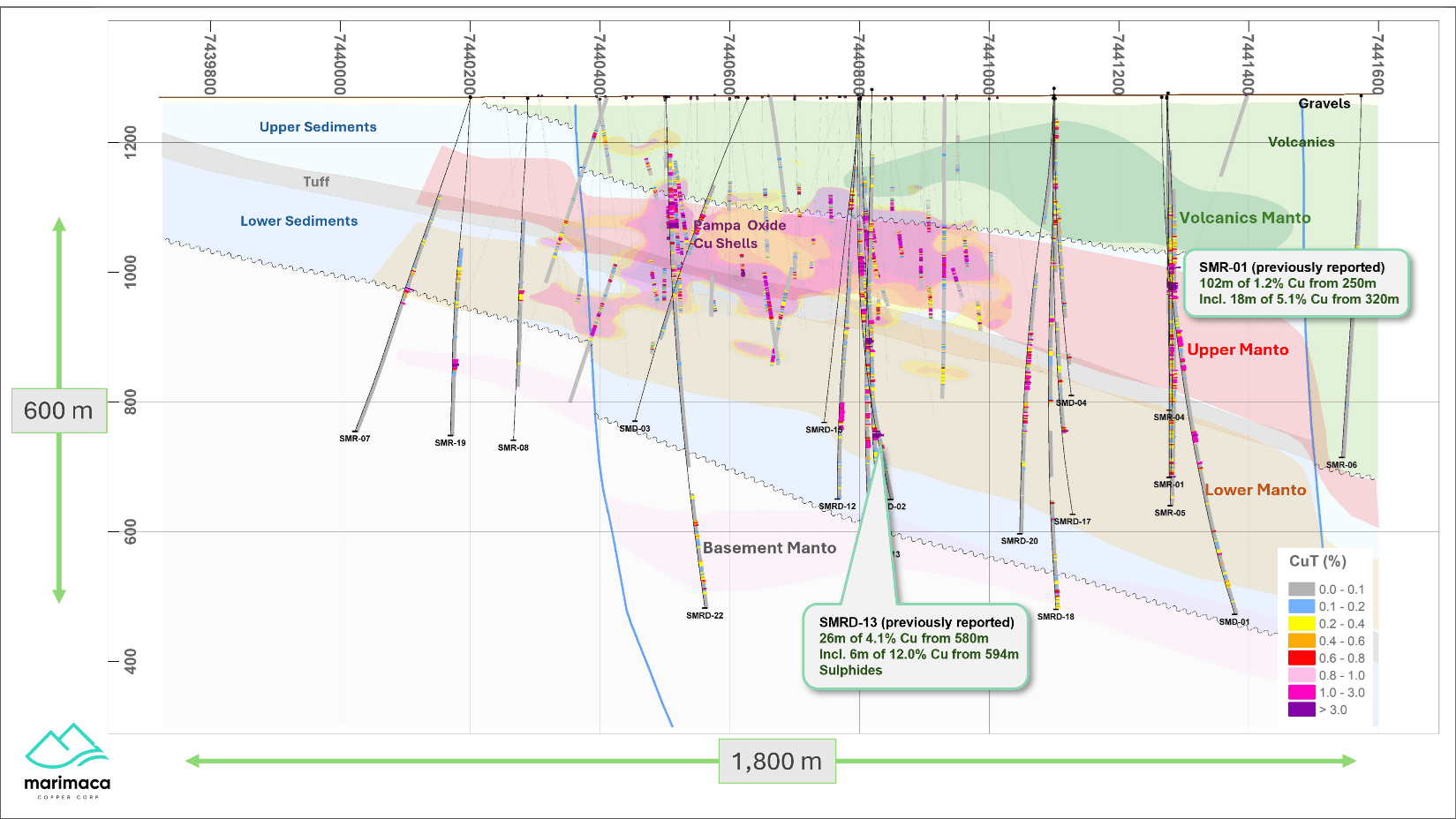

- SMR-19 intersected 16m of 2.29% Cu from 464m within 28m of 1.44% Cu from 464m (sulphides)

- SMR-07 intersected 6m of 3.17% Cu from 334m within 14m of 1.69% Cu from 330m (sulphides)

- North and north-west step-outs continue to demonstrate continuity of mineralization in the favourable sedimentary horizon

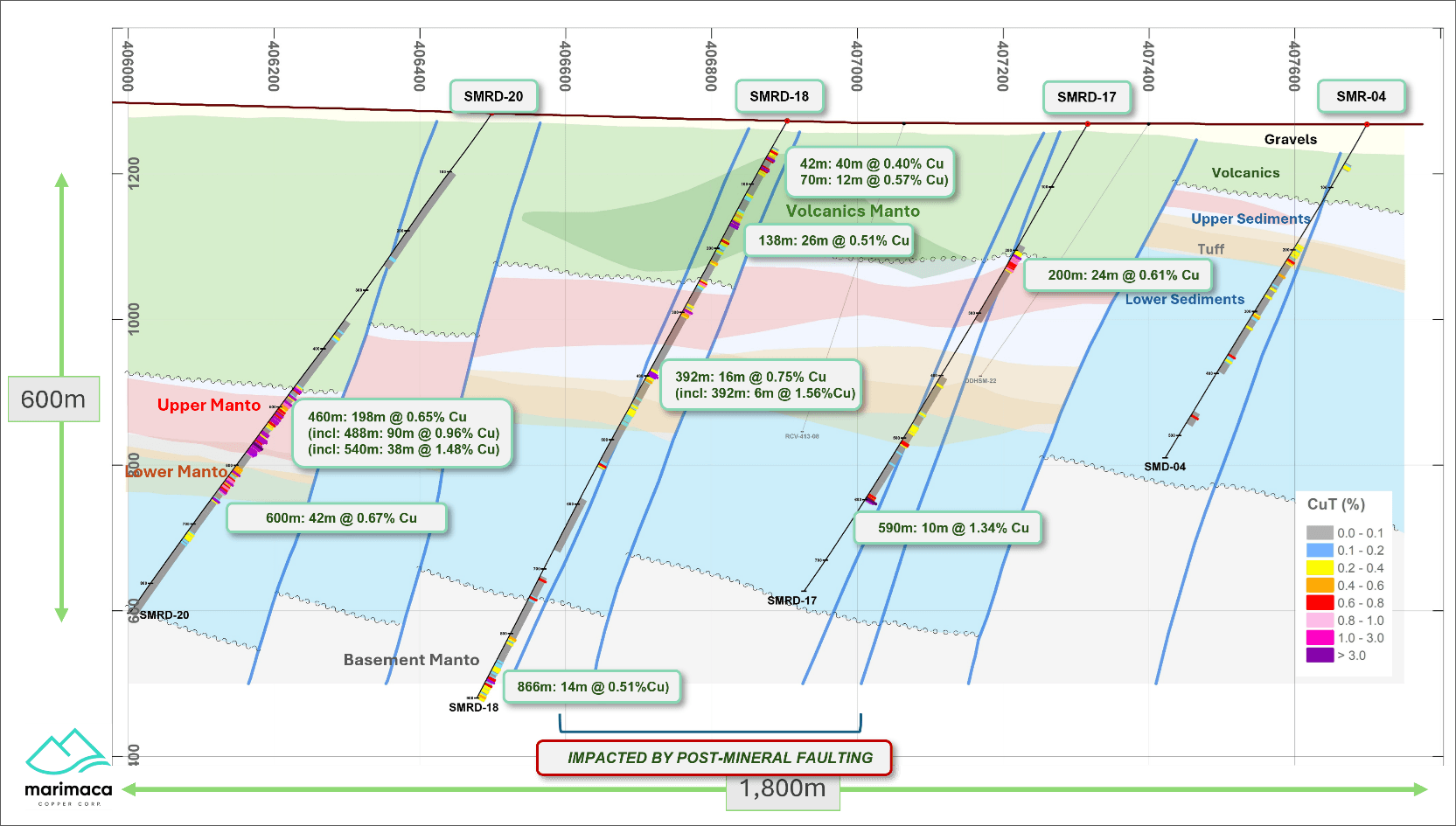

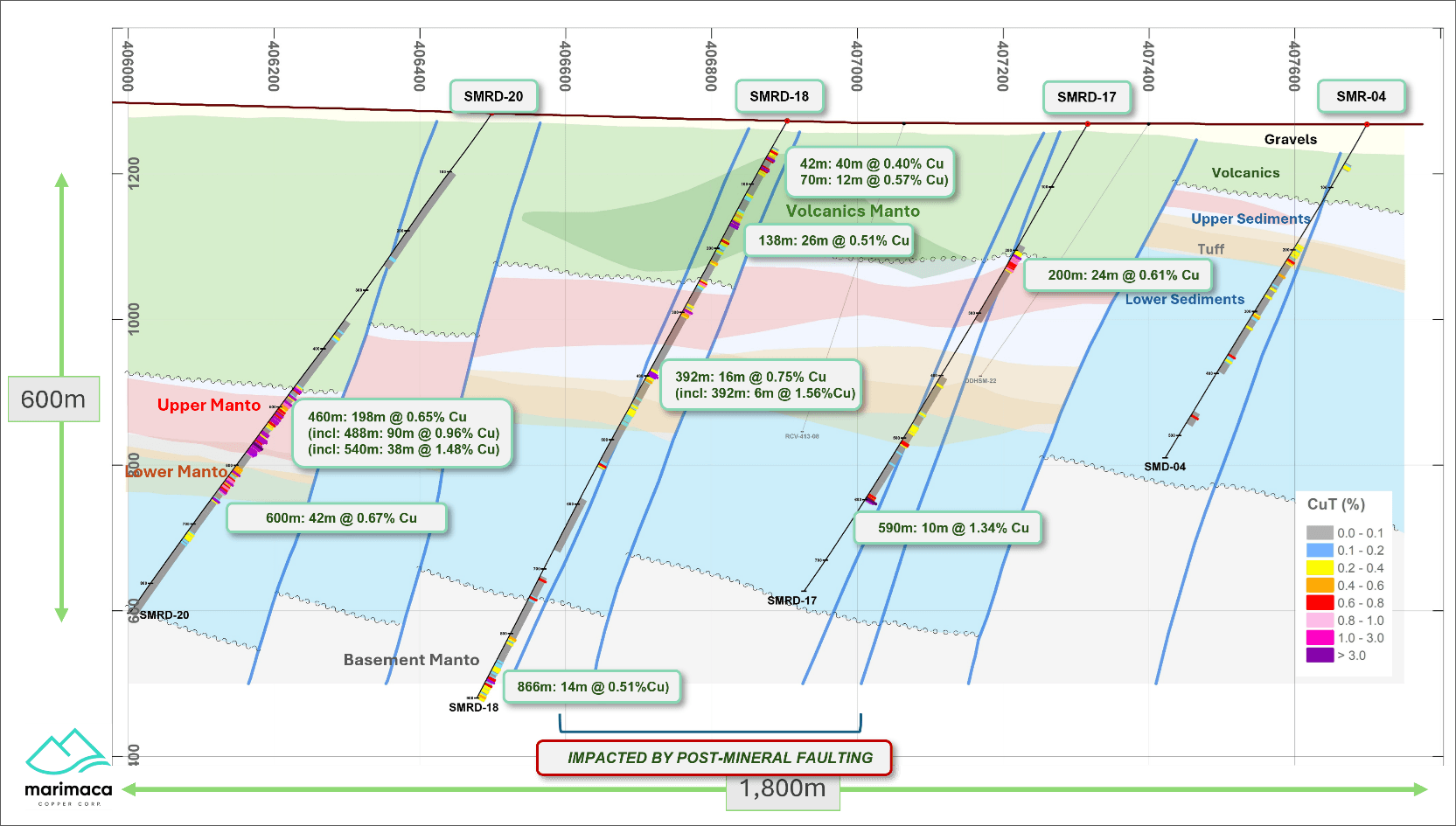

- SMRD-20 intersected 38m of 1.48% Cu from 540m (sulphides) within 90m of 0.96% Cu from 488m, both within a broader intersection of 198m of 0.65% Cu (mixed oxides/sulphides)

- SMRD-17 and SMRD-18 intersected subparallel post-mineral WNW-trending faulting and dykes across favourable horizons

- SMRD-17 intersections, impacted by late faulting, include 10m at 1.34% Cu from 590m (sulphides) and 18m at 0.73% Cu from 206m (oxides)

- SMRD-18 intersections, impacted by late faulting, include 6m at 1.56% Cu from 392m (mixed ) and 40m at 0.40% Cu from 40m (oxides)

- Reverse-circulation scout drilling ("RC drilling"), testing for shallow oxides to the south and west, intersected discreet mineralized volcanics

- SMR-09 intersected 8m of 1.11% Cu from 54m (oxides)

- SMR-10 intersected 4m at 1.68% Cu from 424m (mixed)

- SMR-11 intersected 10m at 0.53% Cu from 444m (oxides)

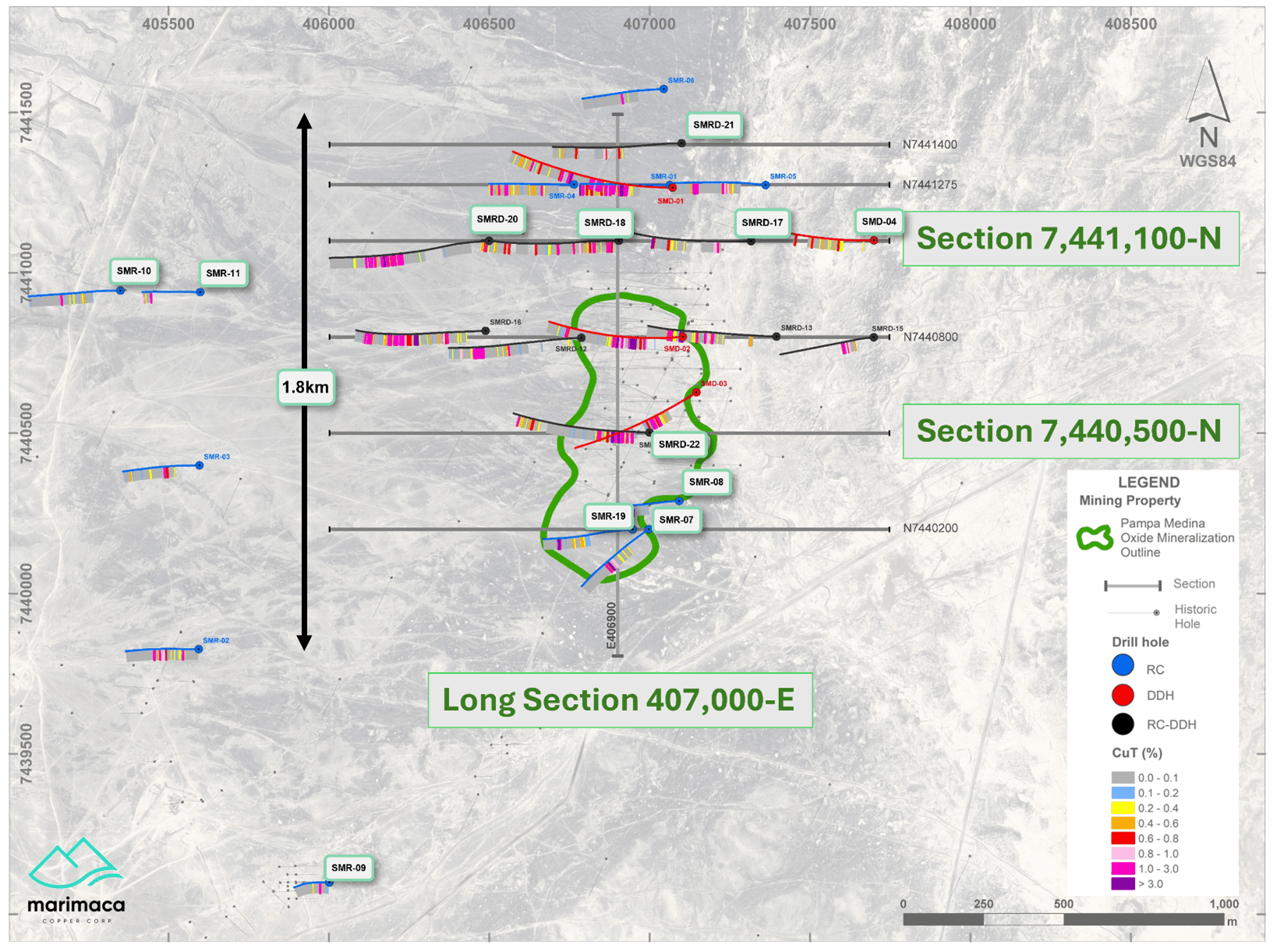

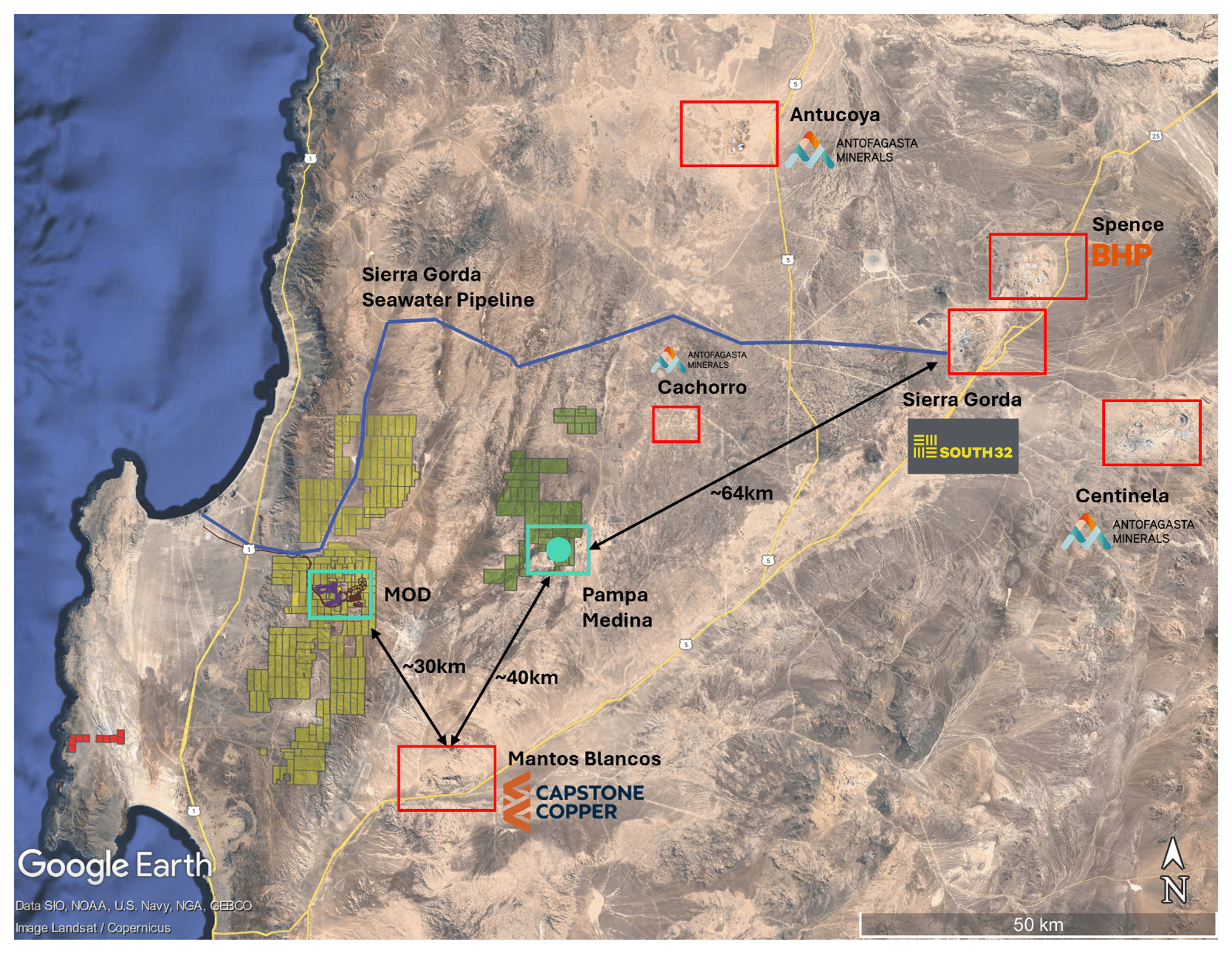

- The favourable mineralized stratigraphic sequence is now defined by drilling across a 1.6km x 1.4km area at the Pampa Medina deposit and remains open – extensional drilling will focus on step outs toward the north and west

- Results conclude the Company's successful Phase I discovery drilling program at Pampa Medina

- The Company has commenced it's 30,000m Phase II program with five rigs currently on site

Sergio Rivera, VP Exploration of Marimaca Copper, commented:

"The discovery drilling program at Pampa Medina was remarkably successful, with the definition of a potentially significant new deposit in Chile. We are encouraged by this new set of intersections demonstrating continuity of the high-grade sedimentary horizon in the south – 900m from the previously announced drilling.

"The 30,000m follow-up campaign, now underway, will provide us with vital geological information to further our understanding of the controls, and extent, of this deposit. Pampa Medina is shaping up to be a tier one opportunity and anchors our vision for growth in the district beyond the rapidly-advancing Marimaca Oxide Deposit."

Hayden Locke, President & CEO, commented:

"The work that Sergio Rivera and the rest of Marimaca's exploration team have delivered at Pampa Medina continues to reinforce our objective at Marimaca: to define credible district growth potential beyond the 50ktpa capacity outlined in the MOD DFS. These results, coupled with our recent RCA for the MOD, is certainly putting us on the path to achieve this objective. We look forward to continuing to define the district scale potential in our Phase II drilling program and updating our stakeholders accordingly."

Overview of Pampa Medina

Pampa Medina is a stratiform manto-style copper deposit dominantly hosted in Jurassic-Triassic sedimentary units (sandstones, conglomerates, tuffs and black shales) overlain by andesitic volcanics and underlain by an Upper Paleozoic complex of metamorphosed sediments, volcanics and intrusions. Key lithological units are intruded by a dyke swarm and affected by post mineral normal faulting. Copper was originally identified in near-surface oxide mineralization dominated by atacamite, chrysocolla and both secondary and primary chalcocite, and has now been identified in high-grade zones of bornite and chalcopyrite which extend at depth beyond the oxide-primary transition.

Following Marimaca's consolidation of the project area and surrounding land packages in 2024, the Company reinterpreted all available geological information and developed an updated geological model for Pampa Medina, which identified the lower sedimentary units of interbedded sandstones, shales and conglomerates as the productive horizons for future drill targeting. Oxide copper mineralization was logged in historical drilling in near-surface, uplifted blocks, with the model of continuity in the intact lithological sequence in deeper blocks for primary mineralization to be tested by Marimaca's 2025 and 2026 drilling campaigns. In addition to the sulphide extensions, the Marimaca discovery drilling has identified opportunities for significant extensions to the oxide footprint of the deposit, most notably to the north and west, which will be followed up on during the Phase II program (30,000m).

Figure 1: Regional Map – Marimaca, Pampa Medina and Regional Infrastructure

Figure 2 – Pampa Medina Deposit and Step-out Drilling Locations

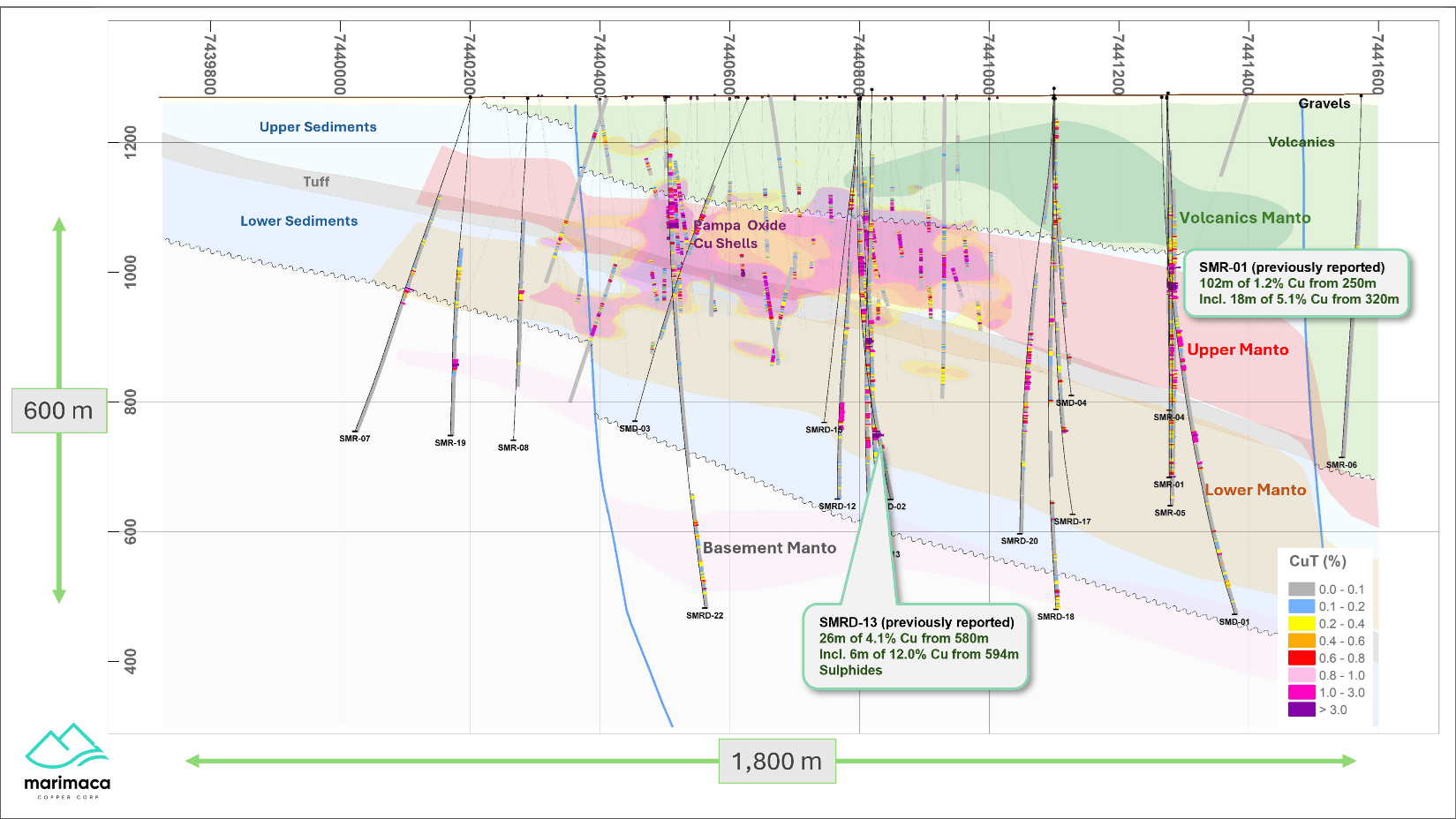

Figure 3 – Pampa Medina Long Section 407,000 E

Figure 4 – Cross Section Looking North – Pampa Medina 7,441,100 N

Figure 5 – Cross Section Looking North – Pampa Medina 7,440,500 N

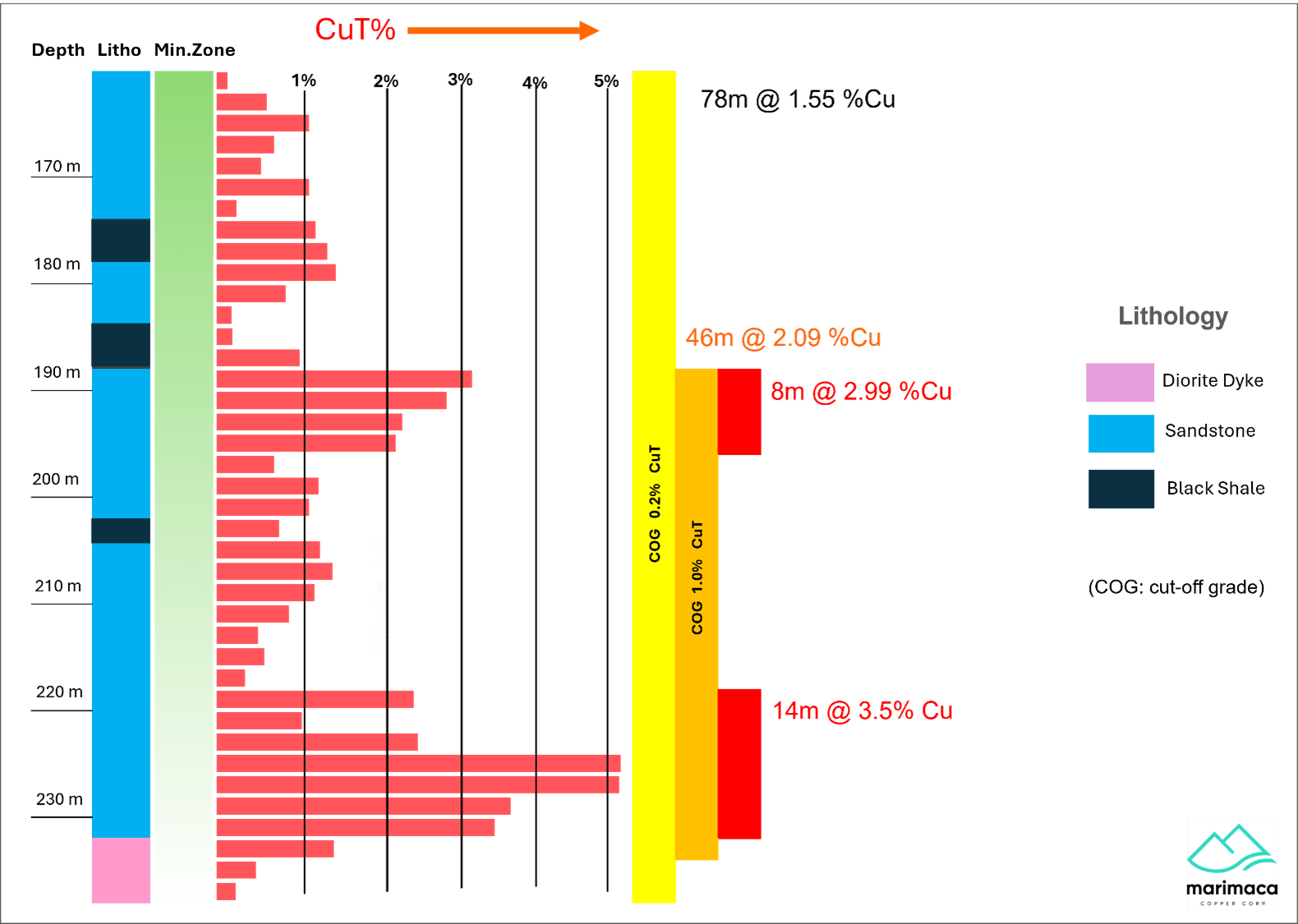

Figure 6 – SMRD-22 Downhole Sequence

| Hole | Total

Depth (m) | | From (m) | To (m) | Intersection

(m) | % CuT |

| SMR-07 | 584 | | 296 | 312 | 16 | 0.52 |

| | 330 | 344 | 14 | 1.66 |

| Including | 334 | 340 | 6 | 3.17 |

| SMR-08 | 578 | | 328 | 350 | 22 | 0.69 |

| SMR-09 | 256 | | 54 | 62 | 8 | 1.11 |

| SMR-10 | 678 | | 424 | 428 | 4 | 1.68 |

| SMR-11 | 548 | | 444 | 454 | 10 | 0.53 |

| | 536 | 548 | 12 | 0.43 |

| SMD-04 | 536 | | 214 | 216 | 4 | 0.59 |

| SMRD-17 | 752 | | 200 | 224 | 24 | 0.61 |

| Including | 206 | 224 | 18 | 0.73 |

| | 590 | 600 | 10 | 1.34 |

| SMRD-18 | 900 | | 42 | 82 | 40 | 0.40 |

| Including | 70 | 82 | 12 | 0.57 |

| | 138 | 164 | 26 | 0.51 |

| Including | 152 | 164 | 12 | 0.86 |

| | 392 | 408 | 16 | 0.75 |

| Including | 392 | 398 | 6 | 1.56 |

| | 866 | 880 | 14 | 0.51 |

| SMR-19 | 594 | | 464 | 492 | 28 | 1.44 |

| Including | 464 | 480 | 16 | 2.29 |

| SMRD-20 | 850 | | 460 | 658 | 198 | 0.65 |

| Including | 488 | 578 | 90 | 0.96 |

| Including | 540 | 578 | 38 | 1.48 |

| | 600 | 642 | 42 | 0.67 |

| SMRD-21 | 697.1 | | 342 | 350 | 8 | 0.46 |

| | 414 | 428 | 14 | 0.53 |

| SMRD-22 | 898 | | 102 | 262 | 160 | 0.92 |

| Including | 162 | 236 | 74 | 1.62 |

| Including | 186 | 234 | 48 | 2.05 |

| | 306 | 328 | 22 | 0.56 |

| | 746 | 756 | 10 | 0.58 |

| | 844 | 856 | 12 | 0.45 |

| | | | | | | |

Table 1: Table of Intersections

| Hole ID | TYPE | Easting | Northing | Elevation | Azimuth | Dip | Depth |

| SMR-07 | RC | 406,996.96 | 7,440,200.50 | 1,269.54 | 240 | -60 | 584 |

| SMR-08 | RC | 407,092.11 | 7,440,288.59 | 1,268.44 | 240 | -60 | 578 |

| SMR-09 | RC | 406,001.19 | 7,439,099.11 | 1,285.64 | 270 | -60 | 256 |

| SMR-10 | RC | 405,350.06 | 7,440,944.92 | 1,310.86 | 270 | -60 | 678 |

| SMR-11 | RC | 405,598.78 | 7,440,939.93 | 1,303.65 | 270 | -60 | 548 |

| SMD-04 | DDH | 407,699.04 | 7,441,101.50 | 1,267.95 | 270 | -60 | 536 |

| SMRD-17 | RCD | 407,316.02 | 7,441,099.03 | 1,268.61 | 270 | -60 | 752 |

| SMRD-18 | RCD | 406,903.96 | 7,441,100.03 | 1,272.63 | 270 | -60 | 900 |

| SMR-19 | RC | 406,946.78 | 7,440,199.94 | 1,270.58 | 270 | -60 | 594 |

| SMRD-20 | RCD | 406,499.15 | 7,441,099.87 | 1,283.59 | 270 | -60 | 850 |

| SMRD-21 | RCD | 407,099.56 | 7,441,404.17 | 1,269.90 | 270 | -60 | 697.1 |

| SMRD-22 | RCD | 406,999.44 | 7,440,502.13 | 1,270.51 | 270 | -60 | 898 |

| | | | | | | | |

Table 2: Drill Collars

Sampling and Assay Protocols

True widths are estimated as 95% of reported intervals, based on down-hole bedding and structural measurements. DDH holes were sampled on a 2m continuous basis, halved by a conventional core splitter on site with one half sent to the Andes Analytical Assay preparation laboratory in Copiapó and the pulps then sent to the same company laboratory in Santiago for assaying. Samples were prepared using the following standard protocol: drying; crushing all sample to -1/4" and passing through a secondary crusher to better than 80% passing -10#; homogenizing; splitting; pulverizing a 400-600g subsample to 95% passing -150#; and a 125g split of this sent for assaying. All samples were assayed for %CuT (total copper); %CuS (acid soluble copper). A full QA/QC program, involving insertion of appropriate blanks, standards and duplicates was employed with acceptable results. Pulps and sample rejects are stored by Marimaca Copper for future reference.

Qualified Person / Competent Person

The technical information in this news release, including the information that relates to geology, drilling and mineralization was prepared under the supervision of, or has been reviewed by Sergio Rivera, Vice President of Exploration, Marimaca Copper Corp, a geologist with more than 40 years of experience and a member of the Colegio de Geólogos de Chile and of the Institute of Mining Engineers of Chile, and who is the Qualified Person for the purposes of NI 43-101 responsible for the design and execution of the drilling program.

The information in this announcement which relates to exploration results for the Pampa Medina Project is based on, and fairly reflects, information and supporting documentation prepared by Sergio Rivera, VP Exploration of Marimaca, a Competent Person who is a member of the Comision Minera (Chilean Mining Commission), Colegio de Geólogos de Chile and of the Institute of Mining Engineers of Chile. Mr. Rivera has sufficient experience that is relevant to the style of mineralisation and types of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Joint Ore Reserves Committee Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. Mr. Rivera consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears.

Contact Information

For further information please visit www.marimaca.com or contact:

Tavistock

+44 (0) 207 920 3150

Emily Moss / Ruairi Millar

marimaca@tavistock.co.uk

Forward Looking Statements

This news release includes certain "forward-looking statements" under (without limitation) applicable Canadian securities legislation, including, without limitation, statements regarding the development of activities at Pampa Medina, the potential growth of Pampa Medina, and the discovery's potential to complement the MOD. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Forward-looking statements reflect the beliefs, opinions and projections on the date the statements are made and are based upon a number of assumptions and estimates that, while considered reasonable by Marimaca Copper, are inherently subject to significant business, economic, competitive, political and social uncertainties and contingencies. Many factors, both known and unknown, could cause actual results, performance or achievements to be materially different from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements and the parties have made assumptions and estimates based on or related to many of these factors. Such factors include, without limitation: risks that the development activities at Pampa Medina will not progress as anticipated, or at all, risks related to share price and market conditions, the inherent risks involved in the mining, exploration and development of mineral properties, the uncertainties involved in interpreting drilling results and other geological data, fluctuating metal prices, the possibility of project delays or cost overruns or unanticipated excessive operating costs and expenses, uncertainties related to the necessity of financing, uncertainties relating to regulatory procedure and timing for permitting submissions and reviews, the availability of and costs of financing needed in the future as well as those factors disclosed in the annual information form of the Company dated March 27, 2025 and other filings made by the Company with the Canadian securities regulatory authorities (which may be viewed at www.sedar.com). Readers should not place undue reliance on forward-looking statements. Marimaca Copper undertakes no obligation to update publicly or otherwise revise any forward-looking statements contained herein whether as a result of new information or future events or otherwise, except as may be required by law.

None of the TSX, ASX or the Canadian Investment Regulatory Organization accepts responsibility for the adequacy or accuracy of this release.

This announcement was authorised for release to the ASX by the Board of Directors of the Company.

Appendix 1 – JORC Code 2012 Table 1 (ASX Listing Rule 5.7.1)

Section 1 Sampling Techniques and Data

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | - Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling.

- Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

- Aspects of the determination of mineralisation that are Material to the Public Report.

- In cases where ‘industry standard' work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information.

|

All current drilling conducted at Sierra Medina (including Pampa Medina, Pampa Norte Extension and Pampa West) was completed under the supervision of a registered professional geologist as a Competent Person/Qualified Person (QP) who is responsible and accountable for the planning, execution, and supervision of all exploration activity as well as the implementation of quality assurance programs and reporting.

- Drilling reported is Reverse Circulation "RC" and Diamond ("DDH") drilling

- Assay samples were prepared at a laboratory site in Copiapó and assayed by Andes Analytical Assay Ltd. (AAA) in Santiago.

- Sierra Medina´s DDH holes are drilled and sampled on a continuous 2-meter basis, halved by a conventional core splitter on site, with one half sent to the Andes Analytical Assay preparation laboratory in Copiapó and the pulps then sent to the same company laboratory in Santiago for assaying.

- Marimaca RC holes are drilled and sampled on a continuous 2-meter basis and riffle split on site up to one-eighth (12.5%) of its volume, after which samples are sent for preparation and assaying.

- Marimaca staff supervised all the drilling and sampling.

- DD recoveries were controlled by accurate core recovery measurement control was extended toward the division process realized in the drill location.

- DD recoveries were measured by core length measurement and compared with the effective core run. Marimaca technical staff checked all data.

- Measured recoveries are over 95% for DDH drilling, without significant variations and unrelated to copper grades.

- RC recoveries were controlled by weighing samples and accurate control was extended toward the division process realized in the drill location.

- RC recoveries were measured in weight percent as compared with a theoretical sample weight. Marimaca technical staff checked all data.

- Measured recoveries are over 95% for RC drilling, without significant variations and unrelated to copper grades.

|

| Drilling techniques | - Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc).

| - Drilling reported is both DDH and RC drilling

- DDH drilling is drilled in HQ and NQ standard core diameters

|

| Drill sample recovery | - Method of recording and assessing core and chip sample recoveries and results assessed.

- Measures taken to maximise sample recovery and ensure representative nature of the samples.

- Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

| - Sierra Medina´s DDH holes are drilled and sampled on a continuous 2-meter basis, halved by a conventional core splitter on site, with one half sent to the Andes Analytical Assay preparation laboratory in Copiapó and the pulps then sent to the same company laboratory in Santiago for assaying.

- Marimaca RC holes are drilled and sampled on a continuous 2-meter basis and riffle split on site up to one-eighth (12.5%) of its volume, after which samples are sent for preparation and assaying.

- Marimaca staff supervised all the drilling and sampling.

- DD recoveries were controlled by accurate core recovery measurement control was extended toward the division process realized in the drill location.

- DD recoveries were measured by core length measurement and compared with the effective core run. Marimaca technical staff checked all data.

- RC recoveries were controlled by weighing samples and accurate control was extended toward the division process realized in the drill location.

- RC recoveries were measured in weight percent as compared with a theoretical sample weight. Marimaca technical staff checked all data.

- Measured recoveries are over 95% for RC drilling, without significant variations and unrelated to copper grades.

|

| Logging | - Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

- Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography.

- The total length and percentage of the relevant intersections logged.

| - All holes were geologically logged on digital data capture.

- The data collected are rock, structure, alteration and mineralization based on drilling intervals, recoveries and analytical results.

- After validation, the mineral and alteration zones were defined.

- The results were entered in the database as a table with all mapped data and a consolidated log of the drill was prepared.

- Most of this work was done by experienced senior consultant geologist supported by consultant junior geologist.

- In addition to measuring deviations, most of the holes were surveyed using an optical tele viewer (OPTV or BHTV), with structures and orientation measurements, which continuously and thoroughly recorded the holes' walls and measured structures.

- The structures were measured in ranks according to their width and the results were reported and plotted on stereographic networks and rosette diagrams.

|

| Sub-sampling techniques and sample preparation | - If core, whether cut or sawn and whether quarter, half or all core taken.

- If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry.

- For all sample types, the nature, quality and appropriateness of the sample preparation technique.

- Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

- Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling.

- Whether sample sizes are appropriate to the grain size of the material being sampled.

| - Sierra Medina´s DDH holes are drilled and sampled on a continuous 2-meter basis, halved by a conventional core splitter on site, with one half sent to the Andes Analytical Assay preparation laboratory in Copiapó and the pulps then sent to the same company laboratory in Santiago for assaying

- The last split yields "sample A", which is sent for preparation and assaying, and "sample B", which is used to obtain drill cuttings (1 kg) and coarse/preparation duplicates and then stored in special facilities on site.

- DDH samples are obtained every 2 meters from a half-core, with the other half stored on site.

- RC holes are drilled and sampled on a continuous 2-meter basis and its samples riffle split on site three times, up to one eighth (12.5%) of its volume.

- The last split yields "sample A", which is sent for preparation and assaying, and "sample B", which is used to obtain drill cuttings (1 kg) and coarse/preparation duplicates, and then stored in special facilities on site.

- Samples are transferred by laboratory personnel from the project to Copiapó, and then the preparation pulps are returned to generate the analysis batches. Upon receipt, sample details are logged and insertion points for quality control samples in the sample flow are determined.

- Samples were prepared using the following standard protocol: drying; crushing all sample to -1/4" and passing through a secondary crusher to better than 80% passing -10#; homogenizing; splitting; pulverizing a 400-600g subsample to 95% passing -150#; and a 125g split of this sent for assaying. All samples were assayed for %CuT (total copper); %CuS (acid soluble copper). A full QA/QC program, involving insertion of appropriate blanks, standards and duplicates was employed with acceptable results. Pulps and sample rejects are stored by Marimaca Copper for future

- Laboratory results are loaded directly from digital assay certificates into the database, in order to minimize error sources.

|

| Quality of assay data and laboratory tests | - The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

- For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

- Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established.

| - Samples are prepared at a laboratory site in Copiapó and assayed by Andes Analytical Assay Ltd. (AAA) in Santiago.

- Samples were prepared using the following standard protocol: drying; crushing all sample to -1/4" and passing through a secondary crusher to better than 80% passing -10#; homogenizing; splitting; pulverizing a 400-600g subsample to 95% passing -150#; and a 125g split of this sent for assaying. All samples were assayed for %CuT (total copper); %CuS (acid soluble copper). A full QA/QC program, involving insertion of appropriate blanks, standards and duplicates was employed with acceptable results. Pulps and sample rejects are stored by Marimaca Copper for future

- All samples are assayed by AAA for total copper (CuT) and soluble copper (CuS). The latter was initially obtained from a specific CuS test.

- Laboratory results are loaded directly from digital assay certificates into the database, in order to minimize error sources.

- The analytical quality control programs implemented at Marimaca involve the use of coarse/preparation and pulp duplicates for precision analyses and standard reference materials (SRM).

- Marimaca has protocols in place for handling analytical results that exceed acceptable limits, which can ultimately trigger re-assays of entire or portions of sample batches.

|

| Verification of sampling and assaying | - The verification of significant intersections by either independent or alternative company personnel.

- The use of twinned holes.

- Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

- Discuss any adjustment to assay data.

| - There are no twinned holes in the dataset

- All logging data was completed, and logging data was entered directly into the deposit database.

- Laboratory results are loaded directly from digital assay certificates into the database to minimize error sources.

|

| Location of data points | - Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

- Specification of the grid system used.

- Quality and adequacy of topographic control.

| - Local contractors carried out the supervision of the drilling operation.

- An experienced topographer surveyed the collars.

- WGS84 UTM coordinates are used.

- Data Well Services carried out the downhole surveys for drill holes.

- Data collected is considered adequate for eventual use in mineral resource estimation.

|

| Data spacing and distribution | - Data spacing for reporting of Exploration Results.

- Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

- Whether sample compositing has been applied.

| - Due to the nature of mineralisation and the type of exploration discovery drilling program the hole spacing is highly variable.

- Data spacing is not considered sufficient to establish geological and grade continuities for Mineral Resource Estimation at the Inferred and Indicated category.

- No sample compositing was applied.

|

| Orientation of data in relation to geological structure | - Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

- If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

| - Drill hole orientation was generally oriented to be sub perpendicular to the mineralisation but variable in places given the nature of the exploration program being conducted

- Assays are reported on a downhole basis

- True widths are estimated as 95% of reported downhole intersection widths

|

| Sample security | - The measures taken to ensure sample security.

| - All drilling assay samples are collected by company personnel or under the direct supervision of company personnel.

- Samples from Marimaca were initially processed at the project site and shipped directly from the property to a laboratory facility for final preparation, and later, upon their return, to the laboratory for analysis.

- Appropriately qualified staff at the laboratories collect assay samples.

- Security protocols implemented maintain the chain of custody of samples to prevent unnoticed contamination or mixing of samples and to make active tampering as difficult as possible.

|

| Audits or reviews | - The results of any audits or reviews of sampling techniques and data.

| - It is the Competent Persons opinion that these processes met acceptable industry standards, and that the information can be reported under both JORC and NI43-101 standards and, in the future, be used for geological and resource modelling.

|

Section 2: Reporting of Exploration Results

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status | - Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

- The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

| - Marimaca Copper Corp. owns a tenement package consisting of approximately 14,500 hectares at the broader Sierra de Medina project area and are a mix of mining concessions and exploration concessions.

- The Sierra de Medina Project are comprising 55 concessions owned by ICAL, a subsidiary of Marimaca Copper Corp.

- The Pampa Medina Project comprises 12 concessions owned by SCM Elenita over which the Company entered into an option agreement to acquire.

- The Madrugador Project comprises 10 concessions owned by SLM Juanita and SLM Madrugador over which the Company entered into an option agreement to acquire.

- There are no known impediments to operating exploration drilling campaigns on the project areas.

|

| Exploration done by other parties | - Acknowledgment and appraisal of exploration by other parties.

| 1. Pampa Medina Concessions - Between 1993 and 1996, Compañía Minera Doña Isabel and Rayrock Ltda carried out an extensive exploration program. The program included a geochemistry program with short Track Drill wells spaced every 50 m along several E–W lines between 2 km and 5 km in length, which extend throughout the district, covering the southeastern part of the Pampa concessions in an area of approximately 460 ha. The aim was to evaluate the rock below the caliche layer. In this area, approximately 600 samples were obtained, representing 40% of the total samples extracted throughout the district, of which 2% of the total have copper anomalies.

- For 2003 and 2004, the right to exploit the Pampa 81 (1/20 and 21/40) and Pampa 47 (1/20 and 21/40) concessions by Minera Rayrock Ltda was established.

- In 2008, Rayrock Ltda carried out two RC drilling campaigns. The first involved 15,729 m distributed in 38 holes with an approximate mesh of 500 m × 500 m and the second campaign involved 14,913 m in 35 holes with a mesh of 125 m ×125 m in an area of 1,000 × 350 m, recognising mainly copper oxides, with some mixed intervals and small amounts of primary mineralisation.

- An exploration campaign was subsequently carried out in 2013, consisting of 45 diamond holes for a total of 18,707 m drilled.

- During 2014, Rayrock Ltda continued with the latest exploration campaign, with the completion of 17 diamond drill holes for a total of 5,264 m drilled.

2. Madrugador Concessions - The Madrugador concessions were previously the subject of limited exploration efforts since the 1980s. Most of the exploration on the Madrugador concessions was conducted by Rayrock from 1993 to 1996 and consisted of diamond and reverse circulation drilling. A total of 23,502 m of diamond and RC drilling in 223 holes had been completed on the property prior to 2005. Proyecta, a Chilean engineering company, conducted a short track RC drilling program on the Madrugador claim in 2005.

- During the period 1994 to 1999, Rayrock conducted geological mapping of the property, a stream sediment and soil/road‐cut sampling survey, as well as limited diamond drilling.

- In 2007 and 2008, Apoquindo Minerals Inc. (Apoquindo) completed 21,177 m of RC drilling in 132 holes and 1,206 m of diamond drilling in eight holes.

- In April 2009, Apoquindo entered into a JV agreement with Minera S.A.

|

| Geology | - Deposit type, geological setting and style of mineralisation.

| - The Pampa Medina mining district is characterised by Jurassic-Triassic volcanic and sediment hosted manto type copper mineralization. Characteristics volcanic hosted, such as shallow Madrugador mineralization, resembles the typical Coastal Belt copper style mineralization and the sediment hosted style is exposed at old mine workings along the Sierra de Valenzuela District and at deep drilling below covered areas extending around where the host sediments are covered by volcanics.

- Main structural system are a block faulting and a complex of dyke swarm.

- The copper mineralisation observed in the drill holes comprises both oxides and sulphides. The predominant oxides correspond to atacamite, azurite and chrysocolla. The oxide zone thickness varies between few metres up to more than 200 m, and irregular mixed zone characterised by a mixture of green copper oxides (mainly atacamite) and copper sulphides (mostly chalcocite, and less chalcopyrite and pyrite). At depths of more than 300 m primary mineralization was observed and consist of chalcopyrite, bornite and variable covellite and pyrite.

- Rock alteration is mostly albitization of sediments and little clay is observed in the upper oxidized zones.

|

| Drill hole Information | - A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

- easting and northing of the drill hole collar

- elevation or RL (Reduced Level – elevation above sea level in metres) of the drill hole collar

- dip and azimuth of the hole

- down hole length and interception depth

- hole length.

- If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

| - Drill hole attribute information is included in a table herein.

|

| Data aggregation methods | - In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated.

- Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

- The assumptions used for any reporting of metal equivalent values should be clearly stated.

| - Length weighted averages were used to calculate grade over width.

- No specific grade cap or cut-off was used during grade width calculations. The total copper (CuT) weighted average grade of the entire interval is calculated for all intervals over 2m samples lengths. Manto-type deposits can be variable in nature resulting in some intervals having a small number of poorly mineralized samples (<0.1% CuT) included in the calculation.

- No metal equivalents have been reported.

|

| Relationship between mineralisation widths and intercept lengths | - These relationships are particularly important in the reporting of Exploration Results.

- If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported.

- If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg ‘down hole length, true width not known').

| - True widths are not known at this time, however drilling generally targets subparallel intersections of the mineralized manto units as understood/interpreted at the time of drilling

- All intersections are reported on a downhole basis.

|

| Diagrams | - Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include but not be limited to a plan view of drill hole collar locations and appropriate sectional views.

| - Please refer to the figures contained herein

|

| Balanced reporting | - Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

| - All significant results have been reported

- Please refer to the tables herein

|

| Other substantive exploration data | - Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

| |

| Further work | - The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling).

- Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

| - Over the course of 2025, the Company intends to complete further exploration work at the project area including:

- Geophysical surveys

- Reverse circulation and diamond core drilling

- Of particular focus will be the potential for extensions from the Pampa Medina Deposit north and west.

|