Aclara Resources Inc. ("Aclara" or the "Company") (TSX:ARA) is pleased to announce the successful completion of a laboratory testing phase undertaken to optimize the metallurgical process and ensure that liquid residues not are generated. This test work forms part of the development program for the extraction of Rare Earth Elements ("REE") from Aclara's ionic clay resource in the Penco Module ("Project") located in the Bio Bio Region, in the south of Chile

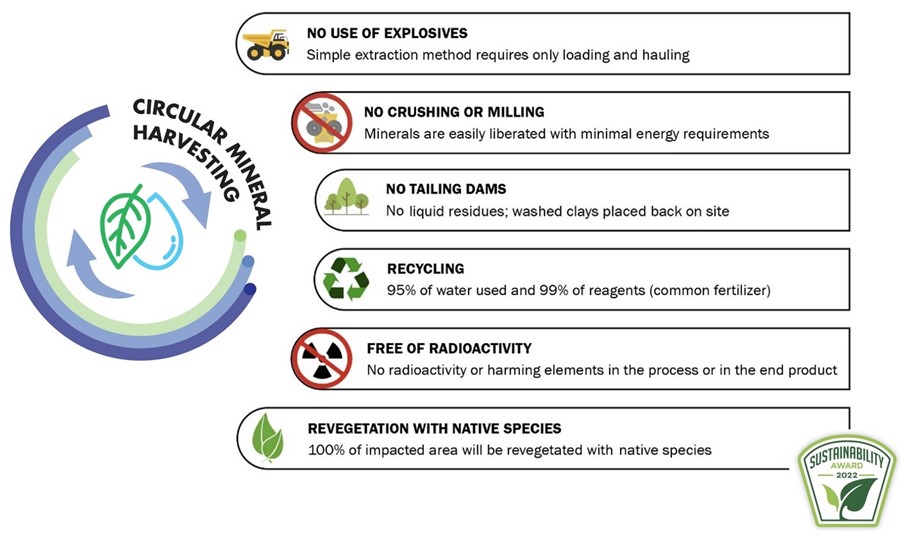

This represents an important milestone in the development of the proposed Aclara REE extraction process, now known as "Circular Mineral Harvesting", as it demonstrates a unique process that not only results in attractive recoveries of REE but also minimizes the associated environmental footprint. The results show that 95% of the fresh water utilized by the process plant is retained within the circuit, that 99% of the main reagent (ammonium sulphate) is recirculated, and that no liquid residues will be produced thus negating the need for a tailings facility. In addition, the mining activities do not require the use of explosives nor subsequent crushing and milling, resulting in a very low carbon footprint operation. The successful completion of this test work materially de-risks the metallurgical attributes of the Project.

Although further optimization opportunities continue to be evaluated by the Aclara team, this achievement allows us to:

- Ensure a stable, closed-circuit process

- Validates the results presented in the PEA with further representative samples

- Improve Dy and Tb recoveries

- Move towards a semi-industrial piloting stage

- Generate intellectual property protected by international patents

The goal of Aclara is to produce a High Purity Heavy Rare Earths ("HREE") concentrate while ensuring a minimal environmental footprint. The Penco Module will not use explosives, nor will there be crushing nor milling circuits in the process flowsheet, which will minimize the use of energy and Green House Gas emissions. In addition, the high percentage of water and reagent recirculation, and the avoidance of the need for a tailings facility, and the production of a final product which is free of deleterious radioactive elements are all key attributes of the novel Aclara process. Finally, Aclara aims to reclaim its production site by growing a native forest on the impacted areas.

Process Flowsheet Introduction

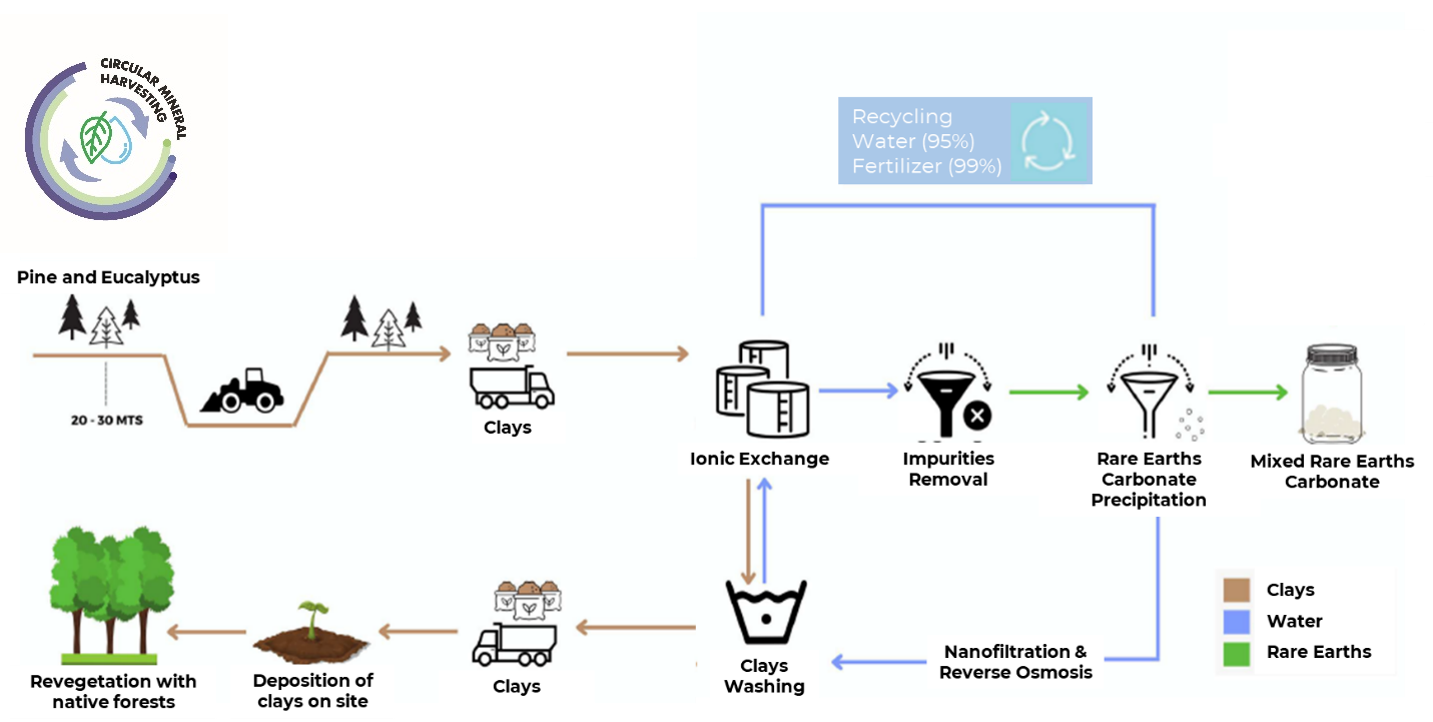

Before delving into the detail of the metallurgical testing program, a brief description of the process named Circular Mineral Harvesting is presented to provide context to the importance of the overall program. REE from the Penco mineral deposit are present in two different mineral forms: as REE elements adsorbed onto the surface of the clays and as REE contained within the mineralized ores, mainly in the form of Monazite. The extraction process is focused on recovering only the REE associated with the clays, as these are known to be soluble in certain acidic solutions with a pH of between 3.0 and 4.0. The process of extracting REE from clays is commonly called "Desorption" or "Leaching", and typically occurs in mildly acidic solutions specifically controlled to maximize the recovery of the REE elements yet minimize the complete dissolution of the host minerals and thereby avoid concentrating unwanted elements. Optimizing the process conditions is key to maximizing the project economics with regards to operational costs, capital costs, environmental footprint and the generation of a final clay material that is safe to return to the mining areas for future revegetation.

The following figure (Figure 1) summarizes the integrated process: mine extraction, desorption, impurities removal and REE carbonation precipitation as final product. It also includes the washing of the processed clays prior to being returned to the depleted mine areas for native reforestation.

Figure 1 - Circular Mineral Harvesting Process flowsheet schematic

Figure 2 highlights the positive attributes associated with the Aclara Circular Mineral Harvesting.

Figure 2 - Aclara Circular Mineral Harvesting Attributes

Background of the Process Flowsheet

The extraction process developed prior to 2021 by Aclara with the support of the University of Toronto consisted of a two-step counter-current desorption process using ammonium sulphate as the main lixiviant followed by a selective precipitation process using ammonium bicarbonate. The pH used in the desorption process was 4.0. The precipitated solid was subsequently washed to recover any remaining ammonium sulphate. The results of this program ("Condition A") were compiled and served as a base case against which to compare the performance of the future metallurgical programs.

Metallurgical Recovery Validation Programme

For the 2021/22 metallurgical program, the first step was to validate the initial results obtained at the University of Toronto using the Condition A process conditions, by testing new, representative samples from the entire Penco deposit and the introduction of a new variant of the lixiviant solution.

Selection of samples

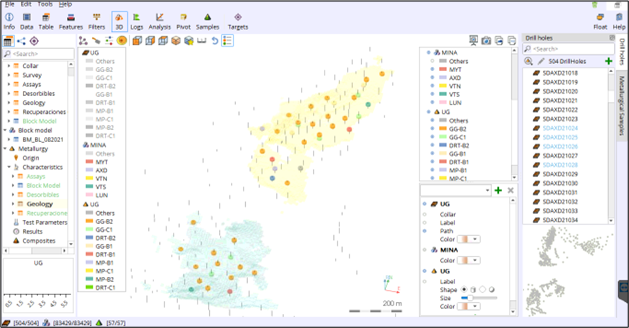

The selection of representative samples for the metallurgical test program was key to ensuring the test results accurately represent the minable mineral resources. It is also important for subsequent testing and process improvements. The metallurgical performance of samples from each mine zone and within each zone may be variable, and such variability plays a part in the selection of samples. To achieve representativeness, the sample selection program considered, amongst others, parameters such as feed grade variations, mineralogy, and physical location. The sample selection process used Cancha© software to both visually and statistically analyze the block models to select a total of 119 samples that were used for this program.

Figure 3- Typical Cancha model used for sample selection

Preparation and management of scope of laboratory testing

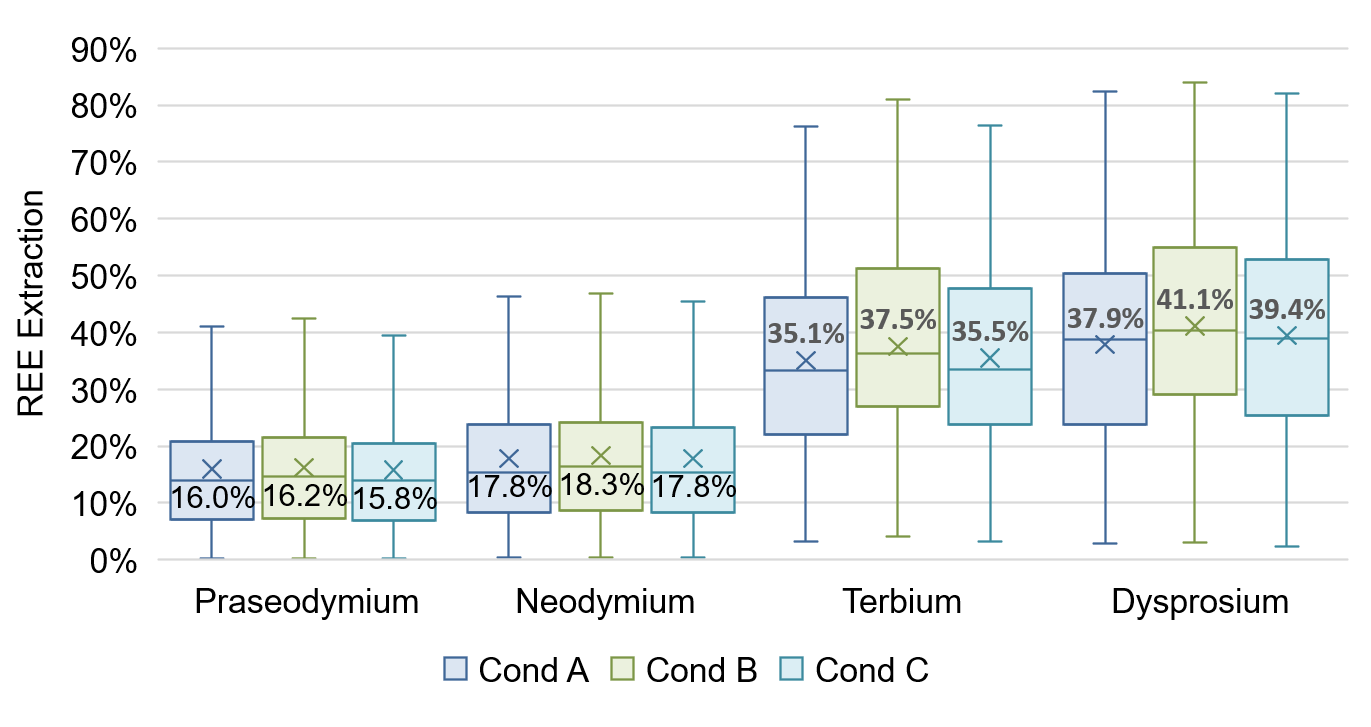

The 2021/22 laboratory test program was performed by SGS Lakefield in Canada. The first stage was to replicate the Condition A process conditions using the newly acquired samples and then introduce two additional process conditions (Conditions B & C) to determine their effectiveness. Test Condition B builds upon the known effect of increasing REE recoveries by using a more acidic solution with a pH of 3.0 instead of 4.0, and introducing a synthetic lixiviant, which emulates the salts generated in the recycling process, while controlling the dissolution of unwanted elements and impurities. Condition C included the same new lixiviant solution as used in Condition B, but at a slightly less acidic pH of 4.0.

In all three cases the main reagent used was ammonium sulphate to remain consistent with the reagent referenced in the environmental permit application. Although the Company withdrew its environmental permit application in March 2022 and will refile a new application in the second quarter of 2023, the environmental regulators are familiar with the proposed use of ammonium sulphate as a reagent, so the Company preferred to continue using this reagent in order to remain consistent with the environmental permit application. Further upside exists in the future to evaluate the performance of other reagents.

In summary:

- Condition A - Repeat University of Toronto base line testing but on new samples at a pH of 4.0

- Condition B - Carry out desorption at a reduced pH of 3.0, plus the introduction of a synthetic lixiviant solution designed to emulate the predicted concentrations of recycled salts generated in the closed-circuit process

- Condition C - Evaluate the impact of the synthetic lixiviant solution used in Condition B but at a pH of 4.0

Analysis of 2021/22 metallurgical results in comparison to the previous programs

The results of the 2021/22 metallurgical program indicate the following:

- Condition A testing on new samples resulted in a validation of recoveries from the initial program at University of Toronto and therefore confirmed the results presented on the Amended and Restated NI 43-101 Technical Report - Preliminary Economic Assessment for the Penco Module Project dated September 15, 2021 ("PEA Technical Report").

- Condition B test results indicated a marginal increase in recoveries over that of Condition A

- Condition C test results showed a small improvement over condition A but not as much as Condition B

Figure 4 shows the results of Condition B and Condition C compared to Condition A as included in the PEA Technical Report:

Figure 4 - Results of REE Extractions Conditions A, B and C

Even though Condition B showed the highest recoveries in terms of NdPr and DyTb, it also resulted in slightly higher quantities of impurities such as aluminum in the final Mixed HREE concentrate. Condition C showed stable recoveries for NdPr and Tb while notably improving the recoveries of Dy, which is the element that drives the most value in our product. Currently laboratory test work is being carried out, where the process conditions will be defined for further demonstration in the pilot plant campaign.

The fact that all recycled salts were used in Condition C has allowed a full understand the parameters needed to design a water treatment plant that ensures that water is fully recycled with an efficiency of 95%, that the ammonium sulphate is recycled with 99% efficiency and that no impurities accumulate in the system with the risk of saturating the process.

Impurities and Water Management in the Process Flowsheet

An extensive testing program was carried out with BQE Water during 2021 and 2022 to validate water treatment requirements for the Penco Module flowsheet, with the objective of maximizing recycling. During this program a process was identified which allows the recycling of water in a closed circuit to meet the goal of zero liquid discharge. The validation of performance at a laboratory scale was completed satisfactorily.

Handling of the impurities in the circuit was also successful, resulting in 90% efficiency in the removal of Manganese (Mn) without major REE losses. Precipitated impurities are mixed with the processed clays (the only output of the plant besides the final product) which fully comply with maximum regulatory levels and thereby allowing the placement of the washed clays back into the field without the need for further treatment. Trials with the processed clays are already underway to demonstrate the amenability of revegetation of the reclaimed site with native species.

Pilot Plant

Semi-industrial Scalability of the Process Flowsheet

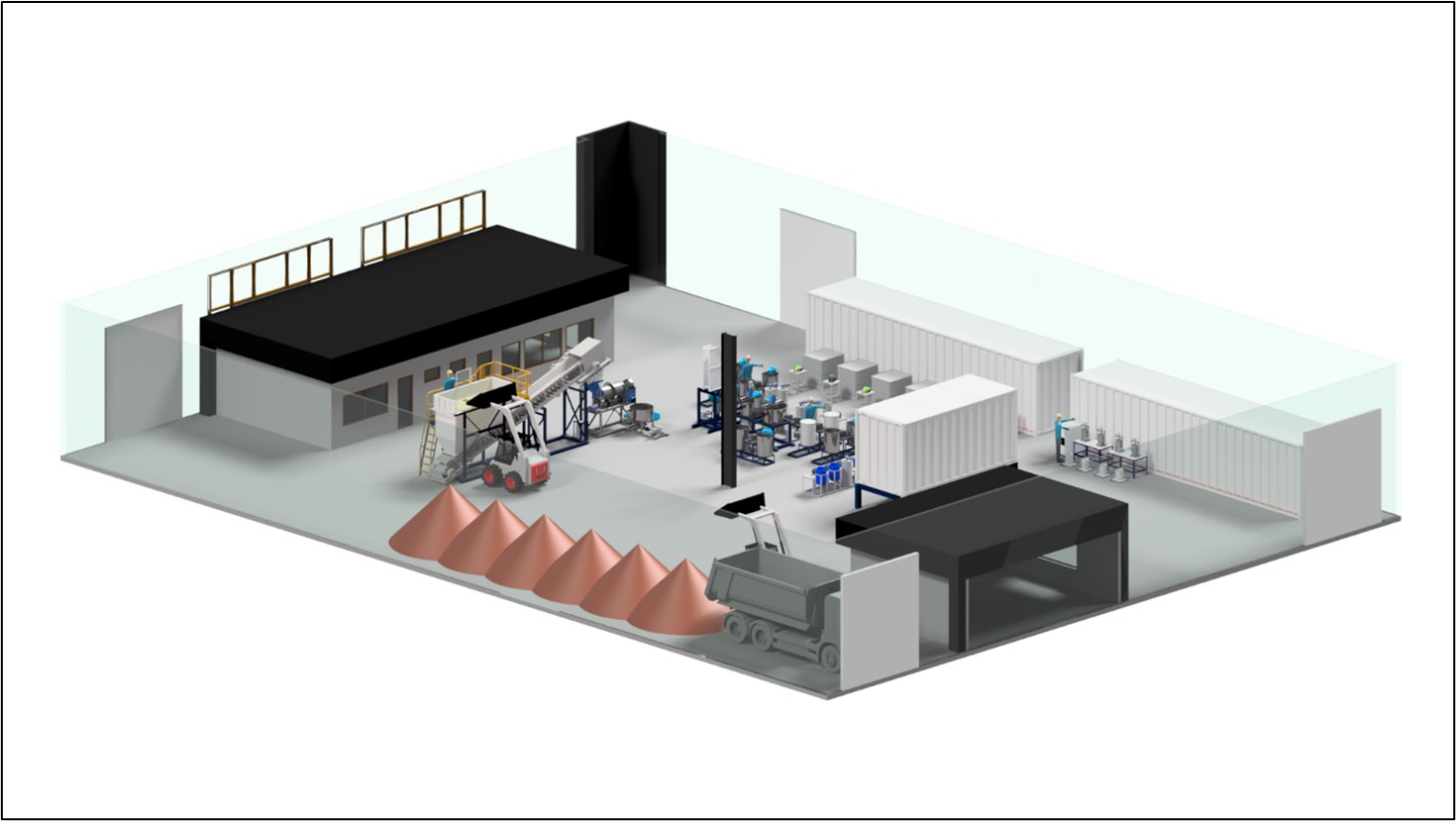

Based on the laboratory results which confirm a metallurgical process with zero liquid discharge, the next step is the execution of a semi-industrial scale pilot test. In that regard, Aclara has begun to build a pilot plant operation with multiple objectives as described below:

- Validate the closed-circuit flowsheet to produce a High Purity HREE concentrate at a semi-industrial scale

- Generate processed clays to demonstrate the chemical stability and amenability for revegetation of the reclaimed site with native species

- Fine-tune the processing parameters for use in the full-scale plant design

- Demonstrate the process flow sheet for use in the Feasibility Study Report

- Generate approximately 50kg of the Mixed REE concentrate for separation trials in support of future offtake agreements

- Demonstrate the simplicity and environmental sustainability of the process to relevant stakeholders

The Company has acquired an industrial warehouse in Concepcion which will house the pilot plant and has put in place the purchase orders for all of the major equipment required for the plant. The plant is scheduled to run continuously for 2 months during the second and third quarter of 2023.

Pilot Plant Design Parameters

- Design throughput is 90 kg/hr. running on a continual 24/7 basis per campaign

- Two campaigns representing 2 of the 5 mining zones covering the initial payback period of the project

- Each campaign is expected to run for 1 month

- A High Purity Mixed REE concentrate will be produced for each campaign

- Final Report is expected by end Q3 2023 for inclusion into Feasibility Study Report

Figure 5 - Pilot Plant Schematic

IP Rights

The proposed process flowsheet has two patents in place that protect this innovation. The first has already been granted in all the countries that were requested: Chile, Brazil, US, and China, and the second patent has recently been filed and is pending to be granted.

Figure 6 - Patent that was awarded in Chile, Brazil, USA and China

Qualified Person

The technical information in this press release relating to the processing facility and metallurgical test work has been reviewed and approved by Stuart Saich, an independent process engineering consultant with 35 years' relevant experience. Mr. Saich is a Fellow member of the Australian Institute of Mining and Metallurgy (FAUSIMM) and therefore an independent Qualified Person (QP) as defined by the National Instrument 43-101, standards of disclosure for minerals projects. The QP confirms that he visited the project site in October 2022 and has been supported by the Head of Processing for Aclara Resources, Ricardo Sepulveda.

Ricardo Sepulveda is a chemical engineer with 18 years of experience in chemical, hydrometallurgical and pyrometallurgical processing related to Copper, Lithium, Rare Earths, Molybdenum, Arsenic, Rhenium, Antimony, among other elements. He has participated as process leader and project manager in PFS, FS and detailed engineering for projects with world class companies. At Aclara, Ricardo is the head of process engineering and leads the metallurgical department including all R&D activities.

About Aclara

Aclara is a development-stage rare earth mineral resources company located in Chile. Aclara is initiating the development of its resources through a project called the Penco Module (the "Penco Module"), which covers a surface area of approximately 600 hectares and which has ionic clays that are rich in rare earth elements. Aclara is currently focused on the development and on the future construction and operation of the Penco Module, which will aim to produce a rare earth concentrate through a processing plant that will be fed by clays from nearby deposits. Aclara's unique extraction process offers several advantages such as: no blasting, crushing or milling required; no tailings dam; minimal water consumption due to a high level of water recirculation; amenable leaching with a fertilizer; and no radioactivity.

Forward-Looking Statements

This news release contains "forward-looking information" within the meaning of applicable securities legislation, which reflects the Company's current expectations regarding future events, including statements with regard to the Company's development program of the extraction of REEs and expectations as to activities conducted and the outcomes resulting therefrom; expectations as to the optimization of the Project's process flowsheet and the Company's success in realizing such optimization opportunities; rates of recovery, efficiencies, and composition of precipitates pursuant to the Company's process flowsheet and any expectations as to results being scaled at a semi-industrial level; construction and operation of the Company's pilot plant; expectations as to activities conducted in connection with the Project, timelines for completion and the success, effect or outcomes resulting therefrom; and the Company's operational goals in the near term and long term and the ability to achieve such goals . Forward-looking information is based on a number of assumptions and is subject to a number of risks and uncertainties, many of which are beyond the Company's control. Such risks and uncertainties include, but are not limited to, the factors discussed under "Risk Factors" in the Company's annual information form dated as of March 30, 2022 filed on the Company's SEDAR profile. Actual results and timing could differ materially from those projected herein. Unless otherwise noted or the context otherwise indicates, the forward-looking information contained in this news release is provided as of the date of this news release and the Company does not undertake any obligation to update such forward-looking information, whether as a result of new information, future events or otherwise, except as expressly required under applicable securities laws.

For further information, please contact:

Ramon Barua

Chief Executive Officer

investorrelations@aclara-re.com

SOURCE: Aclara Resources Inc.

View source version on accesswire.com:

https://www.accesswire.com/724884/Aclara-Confirms-Successful-Completion-of-Its-Process-Flowsheet-at-Lab-Scale