+ Preliminary economic assessment of the Uatnan Mining Project demonstrates attractive economics for a targeted production of approximately 500,000 tonnes of graphite concentrate per annum over a 24-year life of mine, making it one of the World's largest graphite projects in development.

+ The Uatnan Mining Project covers Mason Graphite's Lac Guéret graphite deposit located in Québec, Canada.

+ Results indicate an after-tax IRR of 25.9% and an 8% discount rate NPV of C$ 2,173 million based on current pricing projections for flake concentrate.

+ The Uatnan Mining Project supports NMG's Phase-3 expansion plans with updated operational parameters and production volumes in line with the Company's commercial discussions with OEMs and lithium-ion battery cell makers.

+ NMG has extended its vision of responsible mining to the Uatnan Mining Project, including transition plans for all-electric operations, advanced environmental management and proactive First Nation and community engagement, to provide battery and EV manufacturers with responsibly extracted, environmentally transformed, and locally sourced graphite-based solutions.

+ Shareholders and analysts are invited to attend an Investor Briefing today at 10:30 a.m. ET hosted by NMG's Management Team via webcast: https://us06web.zoom.us/webinar/register/WN_PQUZCrddQuWmw0UUMersow

Nouveau Monde Graphite Inc. ("NMG" or the "Company") ( NYSE: NMG , TSX.V: NOU ) in collaboration with Mason Graphite Inc. ("Mason Graphite") (TSX.V: LLG, OTCQX: MGPHF) releases the results of a preliminary economic assessment ("PEA"), according to National Instrument 43-101 Standards of Disclosure for Mineral Projects ("NI 43-101"), for a new project covering Mason Graphite's Lac Guéret graphite deposit, the Uatnan mining project (the "Uatnan Mining Project") located in Québec, Canada.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230110005458/en/

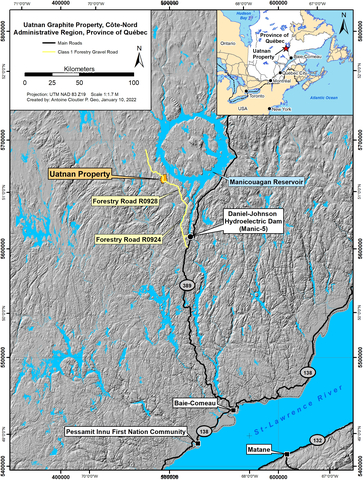

Location of the Uatnan Mining Project (Photo: Business Wire)

The PEA, conducted by engineering firms BBA Inc. ("BBA") and GoldMinds Geoservices Inc. ("GMG"), shows strong economics for NMG's updated operational parameters and production volumes targeting the production of approximately 500,000 tonnes of graphite concentrate per annum over a 24-year life of mine ("LOM"). The proposed Uatnan Mining Project is currently one of the largest projected natural graphite productions in the world as battery and electric vehicle ("EV") manufacturers seek local alternatives for sourcing their graphite-based solutions amidst growing demand and a projected structural deficit of production as of this year as supported by Benchmark Mineral Intelligence (December 2022).

Arne H Frandsen, Chair of NMG, declared: "NMG's vision is to become North America's most important producer of battery grade graphite. The Uatnan Mining Project aligns with our vision of progressive, integrated growth that caters to the market's requirements for high-quality graphite materials, local supplies, ESG-driven development, and large volumes to meet EV production levels. Building on our Matawinie graphite operation's successes, I am confident that our extended technical team's expertise will enable us to develop what is projected to become one of the world's largest graphite mines."

Eric Desaulniers, Founder, President and CEO of NMG, added: "While the core of NMG's technical team is extremely focused on developing and advancing our Phase-2 Matawinie Mine and Bécancour Battery Material projects, it has become increasingly important for our customers and strategic for our shareholders to accelerate the deployment of our Phase 3. It is our intention to capture as much market share as possible during this historical period of growth of lithium-ion battery manufacturing in North America and Europe. I am eager to work with the Innu First Nation of Pessamit and stakeholders from the Manicouagan region to revive the mining development of this world-class deposit. The PEA confirms the tremendous potential of the Uatnan Mining Project as a lever of decarbonization for cleantech markets and socioeconomic growth for local communities. We will leverage our existing Phase-1 facilities, the environmental stewardship measures being developed for our Phase-2 operations, our proprietary technologies, and our demonstrated ESG credentials to advance the Uatnan Mining Project toward development. "

PEA Results: Uncovering the Potential of the Uatnan Mining Project

NMG and its consultants revisited all components of Mason Graphite's original mining project to align the development of the Lac Guéret graphite deposit with today's market opportunity and potential customers' requirements. The most recent technical report from Mason Graphite (SEDAR, Feasibility study update of the Lac Guéret Graphite Project issued on December 11, 2018) planned for a production of 51,900 tonnes of graphite concentrate per annum, with the concentrator and tailings storage facility located offsite in the town of Baie-Comeau, approximately 285 km to the south by road from the mining operations.

The PEA optimizes the Mineral Resources and aims to expand the original mining project tenfold by targeting the production of approximately 500,000 tonnes of graphite concentrate per annum, entirely destined for the anode material manufacturing market. The concentrator has been relocated to be near the deposit with electrical needs that could be sourced from the Manic-5 hydroelectric power station, located 70 km away.

In line with NMG's responsible mining approach, plans include progressive site closure with backfilling of the pit with waste rock as much as possible. Additional characterization of waste rock and tailings will be included in the next engineering phase to select proper tailings and waste rock management technologies. Existing baseline studies will be updated based on the study area to identify any environmental issues, evaluate potential impacts and develop alternatives for the Uatnan Mining Project.

Commercial parameters were set using current projections of pricing prepared by a third-party expert for flake concentrate. Design of the Uatnan Mining Project has been tailored to the needs of the battery and EV market, orienting production volumes for beneficiation in order to produce active anode material. Natural flake graphite is expected to enter a structural deficit as of 2023 due to the continued growth of lithium-ion battery manufacturing, outpacing supply capacity from graphite producers (Benchmark Mineral Intelligence, December 2022). Hence, market perspectives and NMG's active commercial discussions indicate favorable conditions for commercializing the Uatnan Mining Project production.

The following lists the economic highlights and operational parameters developed in the PEA. Graphite is expressed in graphitic carbon ("Cg"):

| Table 1: Operational Parameters of the Uatnan Mining Project | |

| OPERATIONAL PARAMETERS |

|

| LOM | 24 years |

| Nominal annual processing rate | 3.4 M tonnes |

| Stripping ratio (LOM) | 1.3:1 |

| Average grade (LOM) | 17.5% Cg |

| Average graphite recovery | 85% |

| Average annual graphite concentrate production (LOM) | 500,000 tonnes |

| Finished product purity | 94% Cg |

Cautionary Note: The PEA is preliminary in nature and includes Inferred Mineral Resources, considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the PEA will be realized. Mineral resources that are not mineral reserves have not demonstrated economic viability. Additional trenching and/or drilling will be required to convert inferred mineral resources to indicated or measured mineral resources. There is no certainty that the resources development, production, and economic forecasts on which this PEA is based will be realized.

| Table 2: Economic Highlights of the Uatnan Mining Project | |

| ECONOMIC HIGHLIGHTS | Uatnan Mining Project |

| Pre-tax NPV (8% discount rate) | C$ 3,613 M |

| After-tax NPV (8 % discount rate) | C$ 2,173 M |

| Pre-tax IRR | 32.6% |

| After-tax IRR | 25.9% |

| Pre-tax payback | 2.8 years |

| After-tax payback | 3.2 years |

| Initial CAPEX | C$ 1,417 M |

| Sustaining CAPEX | C$ 147 M |

| LOM OPEX | C$ 3,236 M |

| Annual OPEX | C$ 135 M |

| OPEX per tonne of graphite concentrate | C$ 268/tonne |

| Concentrate selling price | US$ 1,100/tonne |

All costs are in Canadian dollars with the exception of the graphite sale price which is provided in US dollars.

Capital expenditure ("CAPEX") and operational expenditure ("OPEX") were established from test work results, supplier quotations and consultant in-house databases. Estimates currently being at the market's peak as influenced by inflationary trends, NMG, Mason Graphite and their consulting firms have refined design, engineering, and construction parameters to enable cost optimization and competitive pricing. Québec's affordable clean hydropower underpins the Uatnan Mining Project's economic structure and supports NMG's undeterred carbon-neutrality commitment.

Considering the significant modifications to Mason Graphite's original project, NMG initiated a name change with the collaboration of the Innu First Nation of Pessamit. The deposit is located on the Nitassinan, the Innu of Pessamit's ancestral territory, in a sector referred to as Ka uatshinakanishkat meaning "where there is Tamarack". Hence, the name Uatnan meaning Tamarack, a conifer prominent in the area, was chosen to identify the property and project. The graphite deposit identified on the property is still referred to as the Lac Guéret deposit.

Initial modelling indicates that the Uatnan Mining Project would create approximately 300 direct jobs.

The Property

The Uatnan property presently consists of 74 map-designated claims totalling 3,999.52 hectares ("ha"), wholly owned (100%) by Mason Graphite. The Uatnan Mining Project lies within Nitassinan, the Innu of Pessamit's ancestral territory and the Rivière-aux-Outardes municipality located in the Côte-Nord administrative region, Québec, Canada, approximately 220 km as the crow flies, north northwest of the closest community, the town of Baie-Comeau. The Uatnan Mining Project is accessible by road 389 and then by following Class 1 forestry roads.

Exploration work on the Uatnan property targeted graphite mineralization and consists to date of airborne geophysics, prospecting, ground geophysics, trenching/channel sampling and core drilling. Bulk surface samples and core samples were also collected for metallurgical and geomechanical tests. Exploration work uncovered significant crystalline flake graphite mineralization, ultimately leading to the identification of Mineral Resources and Mineral Reserves (see Mason Graphite's press release dated November 9, 2015). Due to significant changes to the project scope, as mentioned above, it was decided that the Uatnan Mining Project would revert to a Preliminary Economic Assessment level.

On May 15, 2022, NMG concluded an investment to explore the potential development of the Lac Guéret graphite property (now the Uatnan Property). This agreement aligns with NMG's growth strategy with a view to establishing a large, scalable, and fully vertically integrated natural graphite production, from ore to battery materials, at the western markets' doorstep.

Mineral Resources

Current Mineral Resources (Table 3) have been estimated for the Uatnan property based on 25,956 assay intervals collected from 43,343.1 m of core drilling and 4 surface trenches providing 207 channel samples totalling 721.7 m. Proper quality control measures, including the insertion of duplicate, blank and standard samples, were used throughout the exploration programs and returned within acceptable limits. Although parameters to determine reasonable prospects for eventual economic extraction (RPEE) were updated (Table 4), there are no significant changes between the current Mineral Resources and the Mineral Resources last published on November 9, 2015.

| Table 3: Current Pit-Constrained Mineral Resource Estimate | |||

| IN-PIT CONSTRAINED MINERAL | Tonnes (Mt) | Grade (% Cg) | Cg (Mt) |

| Measured 5.75% | 15.65 | 15.2 | 2.38 |

| Measured Cg > 25% | 3.35 | 30.6 | 1.02 |

| Total Measured | 19.02 | 17.9 | 3.40 |

| Indicated 5.75% | 40.29 | 14.6 | 5.89 |

| Indicated Cg > 25% | 6.33 | 31.6 | 2.00 |

| Total Indicated | 46.62 | 16.9 | 7.89 |

| Indicated + Measured 5.75% | 55.94 | 14.8 | 8.27 |

| Indicated + Measured Cg > 25% | 9.70 | 31.2 | 3.03 |

| Total Measured + Indicated | 65.64 | 17.2 | 11.30 |

| Inferred 5.75% | 15.35 | 14.9 | 2.28 |

| Inferred Cg > 25% | 2.47 | 31.8 | 0.79 |

| Total Inferred | 17.82 | 17.2 | 3.07 |

Notes :

- The Mineral Resources provided in this table were estimated by M. Rachidi P.Geo., and C. Duplessis, Eng., (QPs) of GoldMinds Geoservices Inc., using current Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Standards on Mineral Resources and Reserves, Definitions and Guidelines.

- Mineral Resources which are not Mineral Reserves do not have demonstrated economic viability. The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, market or other relevant issues. The quantity and grade of reported Inferred Mineral Resources are uncertain in nature and there has not been sufficient work to define these Inferred Mineral Resources as indicated or Measured Mineral Resources. There is no certainty that any part of a Mineral Resource will ever be converted into Mineral Reserves.

- The Mineral Resources presented here were estimated with a block size of 3mE x 3mN x 3mZ. The blocks were interpolated from equal-length composites (3 m) calculated from the mineralized intervals.

- The Mineral Resource estimate was completed using the inverse distance to the square methodology utilizing three runs. For run 1, the number of composites was limited to ten with a maximum of two composites from the same drillhole. For runs two and three the number of composites was limited to ten with a maximum of one composite from the same drillhole.

- The Measured Mineral Resources classified using a minimum of four drillholes. Indicated resources classified using a minimum of two drillholes. The Inferred Mineral Resources were classified by a minimum of one drillholes.

- Tonnage estimates are based on a fixed density of 2.9 t/m 3 .

- A pit shell to constrain the Mineral Resources was developed using the parameters presented in Table 4 . The effective date of the current Mineral Resources is January 10, 2023.

- Mineral Resources are stated at a cut-off grade of 5.75% C(g).

| Table 4: Parameters used to develop the pit shell to constrain the Mineral Resources | |

| PARAMETERS | Value |

| Mining cost | C$ 4.00/t mined |

| Processing cost | C$ 36.00/t milled |

| Tailings management cost | C$ 2.00/t milled |

| G&A cost | C$ 5.00/t milled |

| Mill recovery | 85% |

| Concentrate grade | 94% |

| Concentrate price | C$ 1,500 /t |

| Production rate | 3.4 Mtpa |

| Overall pit slope | 50% |

Mining

The mining method selected for the Uatnan Mining Project is a conventional open pit, truck and shovel, drill, and blast operation. Topsoil and overburden would be stripped and stockpiled for future reclamation use. The mineralization and waste rock would be mined with 9-m high benches, drilled, blasted, and loaded into 60-tonne rigid-frame haul trucks with backhoe excavators.

To minimize the environmental footprint of the Uatnan Mining Project, waste rock would be hauled to the tailings storage facility where it would be disposed of with the tailings. As of year 5 of operations, waste rock would be backfilled into the mined-out open pit when possible. The following table presents the subset of Mineral Resources within the pit design for the PEA.

| Table 5: Subset of Mineral Resources within the Pit Design for the PEA | |||

| DESCRIPTION | Tonnes | Cg Grade | In-Situ Graphite |

| Measured resources | 18.7 | 17.9 | 3.3 |

| Indicated resources | 43.5 | 17.1 | 7.4 |

| Total M&I resources | 62.2 | 17.3 | 10.8 |

| Inferred resources | 14.2 | 18.0 | 2.6 |

| Overburden & waste rock | 102.6 |

|

|

The mine would be operated by an owner fleet, seven days per week, 24 hours per day and be comprised of a four‑crew system working on a two-week in, two-week out rotation. NMG intends to deploy a zero-emission operating strategy with a battery-powered fleet of haul trucks and electric equipment as the technology becomes available. In the meantime, the PEA used a base case with a diesel-operated fleet.

Processing & Recovery

The process flow sheet was developed using the same metallurgical basis used for Mason Graphite's updated Feasibility Study issued on December 11, 2018. The main difference between the two flowsheets, apart from the increased plant capacity, is the intended end-use of the material. Given that 100% of the graphite concentrate produced from the Uatnan Mining Project is destined for the battery market, preserving flake sizes is no longer considered in the processing route. Given this consideration, the flowsheet was simplified by reducing the number of both polishing and cleaner flotation stages from four to two. This change minimizes the number of grinding mills and flotation cells required, reducing both the capital and operating costs for the Uatnan Mining Project.

The flowsheet consists of a mineral sizer to reduce the size of the run of mine ("ROM") mineral before it is fed to a SAG mill for primary grinding. The ground mineral then undergoes rougher flotation, after which the reground and scavenged concentrate is combined with the rougher concentrate for further processing. The concentrate then undergoes two additional stages of regrinding, first in a ball mill ahead of the first cleaning step, then a second regrind in a tower mill ahead of secondary cleaning. The resulting concentrate undergoes a final deliming stage to remove low-grade minus 20-micron particles to maximize the final concentrate grade. The concentrator tailings are filtered and delivered to the tailings storage facility. The concentrate is filtered and dried before being trucked 285 km to Baie-Comeau for transport to market.

Economic Evaluation

The CAPEX, summarized below, covers the development of the mine, processing facilities, and infrastructure required for the Uatnan Mining Project. It is based on the application of standard costing methods of achieving a PEA which provides the accuracy of -30% to +50%. The operating cost covers mining, processing, concentrate haulage, tailings and water management, general and administration fees, as well as infrastructure and services.

| Table 6: Summary of Uatnan Mining Project CAPEX Costs | |

| SECTOR | LOM CAPEX ($M) |

| Mining | 61 |

| Site infrastructure | 55 |

| Offsite infrastructure | 184 |

| Water treatment and tailings | 118 |

| Ore crushing and process plant | 548 |

| Indirect | 319 |

| Contingency | 279 |

| TOTAL CAPEX | 1,564 |

| Initial CAPEX | 1,417 |

| Sustaining CAPEX | 147 |

| Table 7: Summary of Main Uatnan Mining Project OPEX Costs | ||

| SECTOR | LOM OPEX Cost ($M) | C$/t Conc. |

| Mining and tailings | 917 | 76 |

| Processing | 1,620 | 134 |

| Water management | 134 | 11 |

| G&A | 565 | 47 |

| TOTAL | 3,236 | 268 |

Next Steps and Quality Assurance

The PEA shows that the Uatnan Mining Project is technically feasible as well as economically viable. It further strengthens NMG's active commercial discussions and the Company's plans for growth through a Phase-3 expansion.

On the basis of these positive results, NMG intends to launch an updated feasibility study in compliance with the option and joint venture agreement signed with Mason Graphite . The Uatnan Mining Project will have to go through the process of the Government of Québec's Environment Quality Act with the objective of obtaining a ministerial decree.

NMG is committed to extending its approach of open and proactive engagement with Indigenous Peoples and local stakeholders to the Uatnan Mining Project. The Company plans to maintain a transparent dialogue with the Innu First Nation of Pessamit as it advances the project development to ensure the respect of their rights, the protection of the environment, their culture, way of life and spirituality, as well as the inclusion of their perspective, and traditional knowledge. NMG also pledges to expand its relationships with stakeholders from all horizons to foster mechanisms for collaboration and shape a project generating shared value.

Shareholders and analysts are invited to attend a webcast Investor Briefing this morning, Tuesday, January 10, 2023, at 10:30 a.m. ET. Hosted by President and CEO Eric Desaulniers with the participation of NMG's Management Team, the briefing will entail a technical presentation followed by a question-and-answer session. Registration should be completed prior to the start of the briefing at: https://us06web.zoom.us/webinar/register/WN_PQUZCrddQuWmw0UUMersow .

There is no certainty that the economic forecasts on which this PEA is based will be realized. The PEA is preliminary in nature and includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the PEA will be realized. Mineral Resources that are not Mineral Reserves have not demonstrated economic viability. Additional trenching and/or drilling will be required to convert Inferred Mineral Resources to Indicated or Measured Mineral Resources. There is no certainty that the resources development, production, and economic forecasts on which this PEA is based will be realized. There are a number of risks and uncertainties identifiable to any new project and usually cover the mineralization, mineral processing, financial, environmental and permitting aspects. NMG's Phase-3 is no different, and an evaluation of the possible risks was undertaken as part of the PEA.

Scientific and technical information presented in this press release was reviewed and approved by André Allaire, P.Eng. (BBA), Jeffrey Cassoff, P.Eng. (BBA), Claude Duplessis (GoldMinds Geoservices), and Merouane Rachidi, P.Geo. (GoldMinds Geoservices) Qualified Persons as defined under NI 43-101.

The PEA for the Uatnan Mining Project, prepared in accordance with NI 43-101 guidelines, will be filed on SEDAR at www.sedar.com , EDGAR at www.sec.gov and on the Company's website at www.NMG.com within 45 days of this press release. Readers are encouraged to read the PEA in its entirety, including all qualifications, assumptions and exclusions that relate to the details summarized in this press release. The PEA is intended to be read as a whole, and sections should not be read or relied upon out of context.

About Nouveau Monde Graphite

Nouveau Monde Graphite is striving to become a key contributor to the sustainable energy revolution. The Company is working towards developing a fully integrated source of carbon-neutral battery anode material in Québec, Canada for the growing lithium-ion and fuel cell markets. With low-cost operations and enviable ESG standards, NMG aspires to become a strategic supplier to the world's leading battery and automobile manufacturers, providing high-performing and reliable advanced materials while promoting sustainability and supply chain traceability. www.NMG.com

About Mason Graphite

Mason Graphite is a Canadian corporation focused on seeking investment opportunities. Its strategy is to develop vertical and horizontal integration in the mining industry, with a special focus on industrial and specialty minerals, notably battery-related materials and their by-products. Its strategy also includes the development of value-added products, notably for green technologies like transport electrification. The Company currently owns 100% of the rights to the Lac Guéret deposit, one of the richest graphite deposits in the world, which is under an Option and Joint Venture Agreement with Nouveau Monde Graphite Inc. (TSX-V: NOU) (NYSE: NMG). Mason Graphite is also the largest shareholder of Black Swan Graphene Inc., a Canadian publicly traded company (TSX-V: SWAN) (OTCQB: BSWGF) focusing on the large-scale production and commercialization of patented high-performance and low-cost graphene products aimed at several industrial sectors, including concrete, polymers, Li-ion batteries and others.

Subscribe to our news feed: https://bit.ly/3UDrY3X

Cautionary Note

All statements, other than statements of historical fact, contained in this press release including, but not limited to those describing the impact of the foregoing on the Uatnan Mining Project economics, PEA results (as such results are set out in the various tables featured above, and are commented in the text of this press release), including CAPEX, OPEX, NPV and IRR, the estimated value of the Uatnan Mining Project, operations development scenarios for the Uatnan Mining Project, commercial and technical parameters, the attractive economics for the Uatnan Mining Project, LOM plans, the Company's intended marketing strategy, , market trends, future graphite prices, the impact of the Uatnan Mining Project on the local communities, including job creation, the projected annual production of the Company's Phase-3 operations, the expected electrification strategy and its intended results and benefits, the potential results and benefits of the Company's proprietary technologies, the timelines and costs related to the various initiatives, deliverables and milestones described in this press release and their expected results, the Company's expected financial and operational performance, the nature of relationships with stakeholders such as the local community including the Innu First Nation of Pessamit, future demand for batteries and EVs, the objective of developing one of the largest fully integrated natural graphite operations in the World, the production of carbon-neutral anode material, Mineral Resource estimates (including assumptions and estimates used in preparing the Mineral Resource estimates), the general business and operational outlook of the Company, the Company's future growth and business prospects, the Company's ESG commitments, initiatives and goals, and those statements which are discussed under the "About Nouveau Monde" paragraph and elsewhere in the press release which essentially describe the Company's outlook and objectives, constitute "forward-looking information" or "forward-looking statements" (collectively, "forward-looking statements") within the meaning of Canadian and United States securities laws, and are based on expectations, estimates and projections as of the time of this press release. Forward-looking statements are necessarily based upon a number of estimates and assumptions that, while considered reasonable by the Company as of the time of such statements, are inherently subject to significant business, economic and competitive uncertainties and contingencies. These estimates and assumptions may prove to be incorrect. Moreover, these forward-looking statements were based upon various underlying factors and assumptions, including the current technological trends, the business relationship between the Company and its stakeholders, the ability to operate in a safe and effective manner, the timely delivery and installation at estimated prices of the equipment supporting the production, assumed sale prices for graphite concentrate , the accuracy of any Mineral Resource estimates, future currency exchange rates and interest rates, political and regulatory stability, prices of commodity and production costs, the receipt of governmental, regulatory and third party approvals, licenses and permits on favorable terms, sustained labor stability, stability in financial and capital markets, availability of equipment and critical supplies, spare parts and consumables, the various tax assumptions, CAPEX and OPEX estimates, the Uatnan Mining Project permits' status, all economic and operational projections relating to the project, local infrastructures, the Company's business prospects and opportunities and estimates of the operational performance of the equipment, and are not guarantees of future performance.

Forward-looking statements are subject to known or unknown risks and uncertainties that may cause actual results to differ materially from those anticipated or implied in the forward-looking statements. Risk factors that could cause actual results or events to differ materially from current expectations include, among others, those risks which are discussed under the "Next Steps and Quality Assurance" paragraph, delays in the scheduled delivery times of the equipment, the ability of the Company to successfully implement its strategic initiatives and whether such strategic initiatives will yield the expected benefits, the availability of financing or financing on favorable terms for the Company, the dependence on commodity prices, the impact of inflation on costs, the risks of obtaining the necessary permits, the operating performance of the Company's assets and businesses, competitive factors in the graphite mining and production industry, changes in laws and regulations affecting the Company's businesses, political and social acceptability risk, environmental regulation risk, currency and exchange rate risk, technological developments, the impacts of the global COVID-19 pandemic and the governments' responses thereto, and general economic conditions, as well as earnings, capital expenditure, cash flow and capital structure risks and general business risks. A further description of risks and uncertainties can be found in NMG's Annual Information Form dated March 22, 2022, including in the section thereof captioned "Risk Factors", which is available on SEDAR at www.sedar.com and on EDGAR at www.sec.gov . Unpredictable or unknown factors not discussed in this Cautionary Note could also have material adverse effects on forward-looking statements.

Many of these uncertainties and contingencies can directly or indirectly affect, and could cause, actual results to differ materially from those expressed or implied in any forward-looking statements. There can be no assurance that forward-looking statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Forward-looking statements are provided for the purpose of providing information about management's expectations and plans relating to the future. The Company disclaims any intention or obligation to update or revise any forward-looking statements or to explain any material difference between subsequent actual events and such forward-looking statements, except to the extent required by applicable law.

The market and industry data contained in this press release is based upon information from independent industry publications, market research, analyst reports and surveys and other publicly available sources. Although the Company believes these sources to be generally reliable, market and industry data is subject to interpretation and cannot be verified with complete certainty due to limits on the availability and reliability of raw data, the voluntary nature of the data-gathering process and other limitations and uncertainties inherent in any survey. The Company has not independently verified any of the data from third-party sources referred to in this press release and accordingly, the accuracy and completeness of such data is not guaranteed.

Disclosures regarding Mineral Resource estimates included in this press release were prepared in accordance with Canadian NI 43-101. The disclosures included in this press release use the terms "Feasibility Study," "Mineral Resource," "Inferred Mineral Resource," "Indicated Mineral Resource," "Measured Mineral Resource," in connection with the presentation of resources, as each of these terms is defined in accordance with the CIM Definition Standards on Mineral Resources and Reserves adopted by the CIM Council, as required by NI 43-101. Unless otherwise indicated, all resource estimates included in this press release have been prepared in accordance with the CIM Definition Standards, as required by NI 43-101.

NI 43-101 is a rule developed by the Canadian Securities Administrators that establish the Canadian standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. These standards differ from the requirements of the United Securities and Exchange Commission (the "SEC"). Accordingly, mineral resource and reserve information included in this press release may not be comparable to similar information made public by United States companies reporting pursuant to SEC reporting and disclosure requirements.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Further information regarding the Company is available in the SEDAR database ( www.sedar.com ), and for United States readers on EDGAR ( www.sec.gov ), and on the Company's website at: www.NMG.com

View source version on businesswire.com: https://www.businesswire.com/news/home/20230110005458/en/

MEDIA

Julie Paquet

VP Communications & ESG Strategy

+1-450-757-8905 #140

jpaquet@nmg.com

INVESTORS

Marc Jasmin

Director, Investor Relations

+1-450-757-8905 #993

mjasmin@nmg.com