February 02, 2023

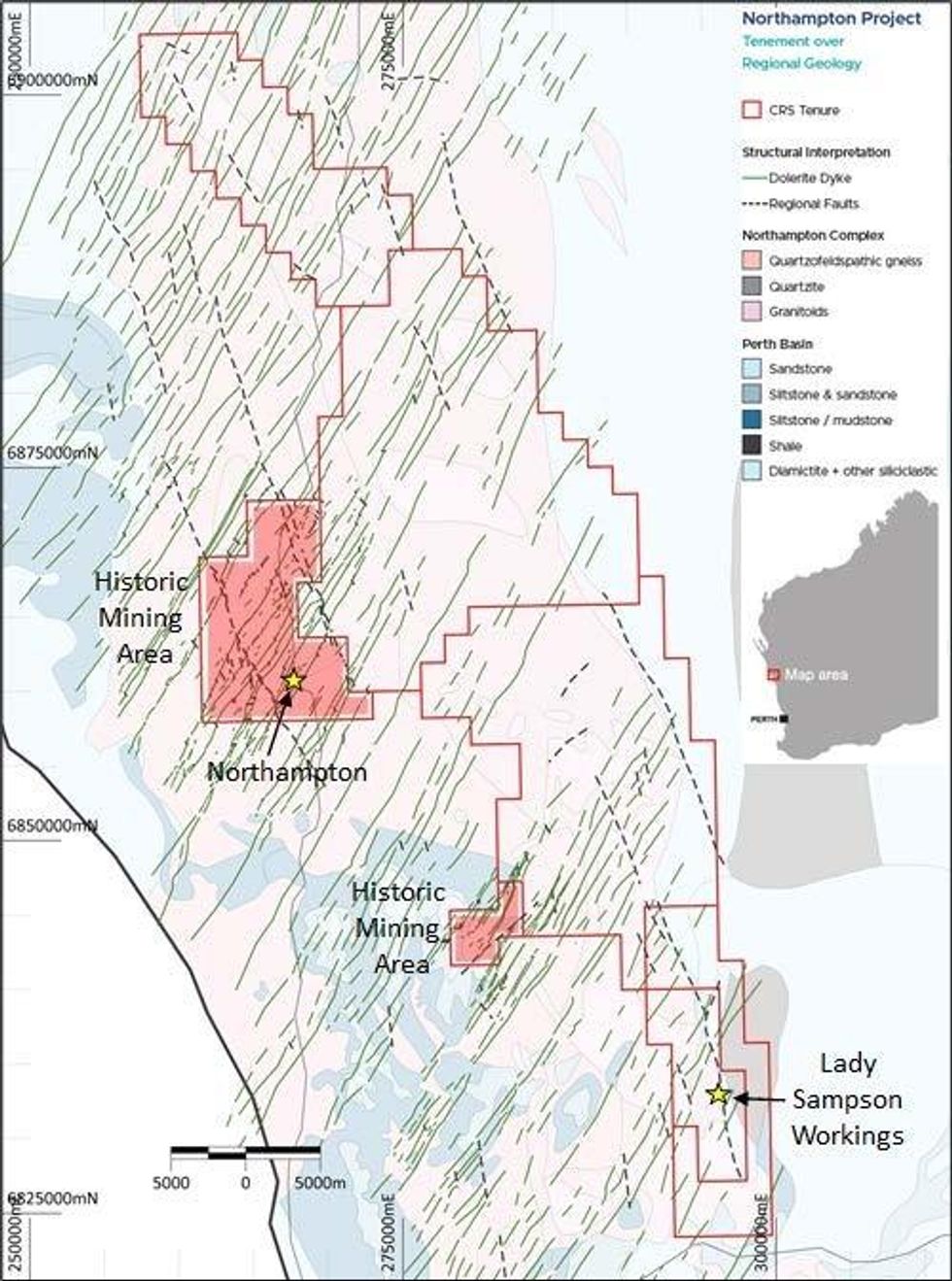

Caprice Resources Ltd (ASX: CRS) (“Caprice” or “the Company”) is pleased to provide an update on the Northampton Polymetallic Project (Northampton), located in the Northampton Mineral Field of Western Australia. Northampton is a historical mining area with over 100 years of base metals mining, with minimal on-ground exploration completed during the last 50 years.

SUMMARY

- RC drilling has commenced at the Lady Sampson prospect, located at the southern end of the Northampton Polymetallic Project

- The program consists of 10-12 holes, testing a north-south base metals anomaly with c.850m planned

- The program is the first drilling to test for base metals mineralisation in this area

RC drilling has commenced at Lady Sampson, approximately 40km south east of the town of Northampton. The last RC program by Caprice in late 2020, close to the Wheal Fortune Mine near the town of Northampton, returned outstanding results of 31m @ 1.1% copper, 2.0% lead & 9g/t silver, incl. 3m @ 3.8% copper, 3.8% lead & 3g/t silver (see ASX: 1/10/20).

This new program, totalling c.850m, is testing north-south oriented base metals Strike drill rig at Lady Sampson, utilising their enviro-pod to minimise ground disturbance mineralisation on the historical Lady Sampson workings.

The hole locations have been guided by historical costeaning, which identified copper and lead rich zones. The results from these costeans also indicated that there may possible zonation between copper dominant and lead-zinc dominant mineralisation (see ASX 6th January 2021).

The drilling should take 8 – 10 days, with assays likely to be returned four to six weeks thereafter.

Managing Director, Andrew Muir, commented:

“We are very excited to finally be testing Lady Sampson following delays in permitting. This will be a major milestone as this part of the Northampton Project has never been drilled before, even though there is evidence of historical base metals mineralisation.”

This announcement has been authorised by the Board of Caprice.

Click here for the full ASX Release

This article includes content from Caprice Resources Ltd, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

CRS:AU

The Conversation (0)

Latest News

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00