Highlights

- Three (3) composite samples were provided to SGS Canada Inc. for Heavy Liquid Separation (HLS) testing to assess the suitability of large-scale Dense Media Separation (DMS) processing.

- Composite 18 achieved a 74.1% recovery to produce a 5.69% Li 2 O concentrate with low iron of 0.42% Fe 2 O 3 .

- Composite 21 achieved a 69.6% recovery to produce a 5.08% Li 2 O concentrate with low iron of 0.55% Fe 2 O 3 .

- Composite 23 achieved a 71.6% recovery to produce a 5.60% Li 2 O concentrate with low iron of 0.46% Fe 2 O 3 .

- The next phase of metallurgy work will include additional HLS test work on other areas of the main mineralized zone at the Cisco Project.

Q2 Metals Corp. (TSX.V: QTWO | OTCQB: QUEXF | FSE: 458) (" Q2 " or the " Company ") is pleased to announce the successful results of the first phase of metallurgical test work on drill core samples collected from the 2024 drill program at the Cisco Lithium Project (the "Project" or the "Cisco Project"), located within the greater Nemaska traditional territory of the Eeyou Istchee James Bay, Quebec, Canada.

The objective of the preliminary test program was to achieve a spodumene concentrate at ~70% recovery with Heavy Liquid Separation ("HLS") test work to confirm the potential suitability of a Dense Media Separation ("DMS") process. The results of this test work confirms that strong recoveries can be achieved with a DMS circuit and as expected, the low iron content of the head samples continues through to the concentrate.

"We're extremely encouraged with the results of this first round of metallurgical testing that confirms that DMS driven processing can be implemented at Cisco. Magnetic or flotation treatments were not utilized in this round due to the success of the HLS tests. The strong recovery combined with low iron content are the highlights so far," stated Neil McCallum, Q2 Metals VP of Exploration. "The next phase of metallurgy test work will be designed to expand upon these positive results and to maximize the concentrate grade and recovery rates at increased scale."

The metallurgical test program for the Cisco Project was completed by SGS Canada Inc. ("SGS") at their laboratory in Quebec City, Quebec, Canada and is focused on industry standard and cost-effective processing techniques applicable to spodumene pegmatite.

Sample Description:

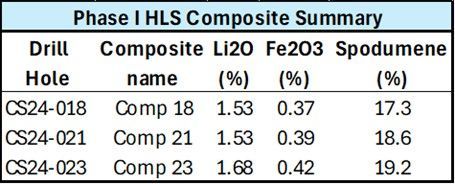

Each of the three composite samples consisted of approximately 45 Kg of material derived from quarter-split drill core material (Table 1). The composite samples were selected from approximately 43 metres of continuous mineralization from drill holes CS24-018, 21 and 23. The material from each composite was blended prior to performing the test work.

Table 1. Composite Sample Description

Test Work Description:

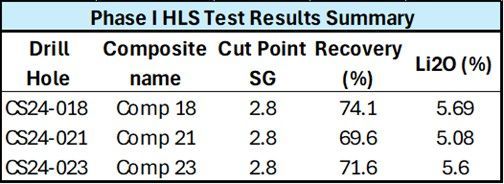

A five-kilogram subset of the blended composite material was further crushed to -9.5 millimetres ("mm") and -6.3 mm to test the applicability of DMS. The -6.3mm was found to be an optimal crush size, and the results of which are summarized below.

A series of sink/float HLS tests were performed on each sample. No magnetic separation was performed on the samples.

At a crush size of -6.3mm, the lithium recovery ranged between 70% and 74% with a concentrate grade between 5.08% and 5.96% Li 2 O:

- Composite 18 achieved a 74.1% recovery with a specific gravity ("SG") cut point of 2.80 to produce a 5.69% Li 2 O concentrate with low iron of 0.42% Fe 2 O 3 .

- Composite 21 achieved a 69.6% recovery with a cut point of 2.80 SG to produce a 5.08% Li 2 O concentrate with low iron of 0.55% Fe 2 O 3 .

- Composite 23 achieved a 71.6% recovery with a cut point of 2.80 SG to produce a 5.60% Li 2 O concentrate with a low iron of 0.46% Fe 2 O 3 .

Table 2. Summary of HLS Testing

Figure 1. Image of HLS sink/float products from Comp 18

Next Steps:

Further work by SGS will test both the necessity of magnetic separation to treat any wall-rock that may or may not be included in the processing stream as well as assess the potential for a flotation circuit to the processing scenario to maximize recovery of the fine material and the rejected middlings of the material of the primary DMS circuit.

Additional HLS test work will be completed on other areas of the main mineralized zone at the Cisco Project to confirm the recoveries in other regions.

Qualified Person

Neil McCallum, B.Sc., P.Geol, a registered permit holder with the Ordre des Géologues du Québec and Qualified Person as defined by NI 43-101 ("QP") has reviewed and approved the technical information in this news release. Mr. McCallum is a director and the Vice President Exploration for Q2.

ABOUT Q2 Metals Corp.

Q2 Metals is a Canadian mineral exploration company focused on the Cisco Lithium Project located within the greater Nemaska traditional territory of the Eeyou Istchee, James Bay, Quebec, Canada.

The Cisco Project is comprised of 801 claims, totaling 41,253 hectares, with the main mineralized zone just 6.5 km from the Billy Diamond Highway, which transects the Project. The Town of Matagami, rail head of the Canadian National Railway, is approximately 150 km to the south.

The Cisco Project has district-scale potential with an initial Exploration Target estimating a range of potential lithium mineralization and grade of 215 to 329 million tonnes at a grade ranging from 1.0 to 1.38% Li 2 O , based only on the first 40 holes drilled.

Drill testing continues with mineralization open at depth and along strike with potential for significant expansion at the Cisco Mineralized Zone. The 2025 Summer Program is ongoing, with rolling assay results anticipated in the coming weeks and months as the Company works towards an initial resource estimate.

ABOUT SGS:

SGS is the world's leading testing, inspection and certification company. SGS is recognized as the global benchmark for quality and integrity. With more than 99,500 employees, SGS operates a network of over 2,500 labs and business facilities combining the precision and accuracy that define Swiss companies to help organizations achieve the highest standards of quality, compliance and sustainability.

FOR FURTHER INFORMATION, PLEASE CONTACT:

| Alicia Milne | Jason McBride | Chris Ackerman |

| President & CEO | Investor Relations Manager | Corporate Development |

| Alicia@Q2metals.com | Jason@Q2metals.com | Chris@Q2metals.com |

Telephone: 1 (800) 482-7560

E-mail: info@Q2metals.com

Follow the Company: Twitter , LinkedIn , Facebook , and Instagram

Sampling, Analytical Methods and QA/QC Protocols

All drilling is conducted using a diamond drill rig with NQ sized core and all drill core samples are shipped to SGS Canada's preparation facility in Val D'Or, Quebec, for standard sample preparation (code PRP92) which includes drying at 105°C, crushing to 90% passing 2 mm, riffle split 500 g, and pulverize 85% passing 75 microns. The pulps are then shipped by air to SGS Canada's laboratory in Burnaby, BC, where the samples are homogenized and subsequently analyzed for multi-element (including Li and Ta) using sodium peroxide fusion with ICP-AES/MS finish (code GE_ICM91A50). The reported Li grade will be multiplied by the standard conversion factor of 2.153 which results in an equivalent Li 2 O grade. Drill core was saw-cut with half-core sent for geochemical analysis and half-core remaining in the box for reference. The same side of the core was sampled to maintain representativeness.

A Quality Assurance / Quality Control (QA/QC) protocol following industry best practices has been incorporated into the sampling program. Measures include the systematic insertion of quartz blanks and certified reference materials (CRMs) into sample batches at a rate of approximately 5% each. Additionally, analysis of pulp-split and reject-split duplicates was completed to assess analytical precision. The QP has verified the QA/QC results of the analytical work.

Forward-Looking Statements

This news release contains forward-looking statements and forward-looking information (collectively, "forward-looking statements") within the meaning of applicable Canadian legislation. Forward-looking statements are typically identified by words such as: "believes", "expects", "anticipates", "intends", "estimates", "plans", "may", "should", "would", "will", "potential", "scheduled" or variations of such words and phrases and similar expressions, which, by their nature, refer to future events or results that may, could, would, might or will occur or be taken or achieved. Accordingly, all statements in this news release that are not purely historical are forward-looking statements and include statements regarding beliefs, plans, expectations and orientations regarding the future including, without limitation, any statements or plans regard the geological prospects of the Company's properties and the future exploration endeavors of the Company. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance and actual results or developments may differ materially from those in the forward-looking statements. Forward-looking statements are based on a number of material factors and assumptions.

Forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause actual results to differ materially from those anticipated in such forward-looking statements. The forward-looking statements in this news release speak only as of the date of this news release or as of the date specified in such statement. Forward looking statements in this news release include, but are not limited to, statements with respect to the the objective of the metallurgy test work, the next phase of metallurgical test work on other areas of the main mineralized zone at the Cisco Project, the potential scale of the Cisco Project, the focus of the Company's current and future exploration and drill programs, the scale, scope and location of future exploration and drilling activities, the Company's expectations in connection with the projects and exploration programs being met, the Company's objectives, goals or future plans, statements, exploration results, potential mineralization, the estimation of mineral resources, exploration and mine development plans, timing of the commencement of operations and estimates of market conditions. Factors that could cause actual results to differ materially from those in forward-looking statements include failure to obtain necessary approvals, variations in ore grade or recovery rates, changes in project parameters as plans continue to be refined, unsuccessful exploration results, changes in project parameters as plans continue to be refined, results of future resource estimates, future metal prices, availability of capital and financing on acceptable terms, reallocation of proposed use of funds, general economic, market or business conditions, risks associated with regulatory changes, defects in title, availability of personnel, materials and equipment on a timely basis, accidents or equipment breakdowns, uninsured risks, delays in receiving government approvals, unanticipated environmental impacts on operations and costs to remedy same. Readers are cautioned that mineral exploration and development of mines is an inherently risky business and accordingly, the actual events may differ materially from those projected in the forward-looking statements. Additional risk factors are discussed in the section entitled "Risk Factors" in the Company's Management Discussion and Analysis for its recently completed fiscal period, which is available under Company's SEDAR profile at www.sedarplus.com .

Should one or more of these risks or uncertainties materialize, or should assumptions underlying the forward-looking statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected. Although the Company has attempted to identify important risks, uncertainties and factors which could cause actual results to differ materially, there may be others that cause results not to be as anticipated, estimated or intended. The Company does not intend, and does not assume any obligation, to update this forward-looking information except as otherwise required by applicable law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/97dca6bb-3cdf-4710-aa00-f22e82de67dc

https://www.globenewswire.com/NewsRoom/AttachmentNg/2823105f-f51d-4c29-aa4e-346de557c044

https://www.globenewswire.com/NewsRoom/AttachmentNg/201de86a-ca17-4a71-877e-769eeca9551c