FPX Nickel Corp. (TSXV: FPX) (OTCQB: FPOCF) (" FPX " or the " Company ") is pleased to announce results from Phase 1 of an ongoing three-phase metallurgical test program to support the continued development of the Company's Baptiste Nickel Project (" Baptiste " or the " Project ") at the Decar Nickel District in central British Columbia. The metallurgical test program is aimed at validating and optimizing the flowsheet outlined in the Project's 2020 Preliminary Economic Assessment (" PEA "), and to support the development of a preliminary feasibility study (" PFS ").

Highlights

- Phase 1 testwork has confirmed the PEA flowsheet and has indicated the potential to achieve nickel recoveries up to 5% higher than the 85% Davis Tube Recoverable ("DTR") nickel recovery assumed in the 2020 PEA

- Comminution testing has confirmed Baptiste material as being consistent, medium-hard to hard, and mildly abrasive across all mining phases, pointing toward a consistent grinding requirement in sync with the PEA basis

- Pilot-scale grinding and primary magnetic separation testing indicated:

- Nickel recoveries up to 5% higher than those observed in previous bench-scale testing, owing to the preferential grinding of the deposit's dense awaruite nickel mineralization via cyclone classification

- Cyclone classification may also result in a reduction of recovered mass in the primary magnetic separation circuit, thereby reducing regrind requirements

- Pilot-scale cleaner magnetic separation has confirmed the ability to create a magnetics-only feed to the flotation circuit, thereby confirming the starting point for previous flotation testwork and the PEA basis

- Phase 2 testwork is underway, focusing on validation and optimization of flotation parameters to confirm the production of a high-grade nickel concentrate, as well as the potential production of a by-product iron ore concentrate, with results anticipated in the first quarter of 2022

- Phase 3 testwork will commence shortly, including hydrometallurgical testwork to validate battery material supply chain integration, larger-scale pilot testing to crystalize Phase 1's indicated recovery benefits, and variability testing, with results anticipated in the third quarter of 2022

"The scale-up from bench- to pilot-scale testing has not only confirmed the effectiveness of Baptiste's PEA flowsheet, but also revealed the potential to improve nickel recovery by up to 5% over the PEA basis," commented Martin Turenne , FPX Nickel's President and CEO. "By introducing conventional cyclone classification into the process test work, we can better estimate the expected nickel recovery in a full-scale operation. In the case of the Baptiste deposit, significant upside to liberation is observed due to hydro-cyclone classification and the associated preferential grinding due to the dense nature of Baptiste's awaruite nickel mineralization. It is estimated that every percentage point increase in recovery yields a US$56 million improvement in after-tax NPV 8% , based on PEA metrics."

Three-Phase Metallurgical Testwork Program

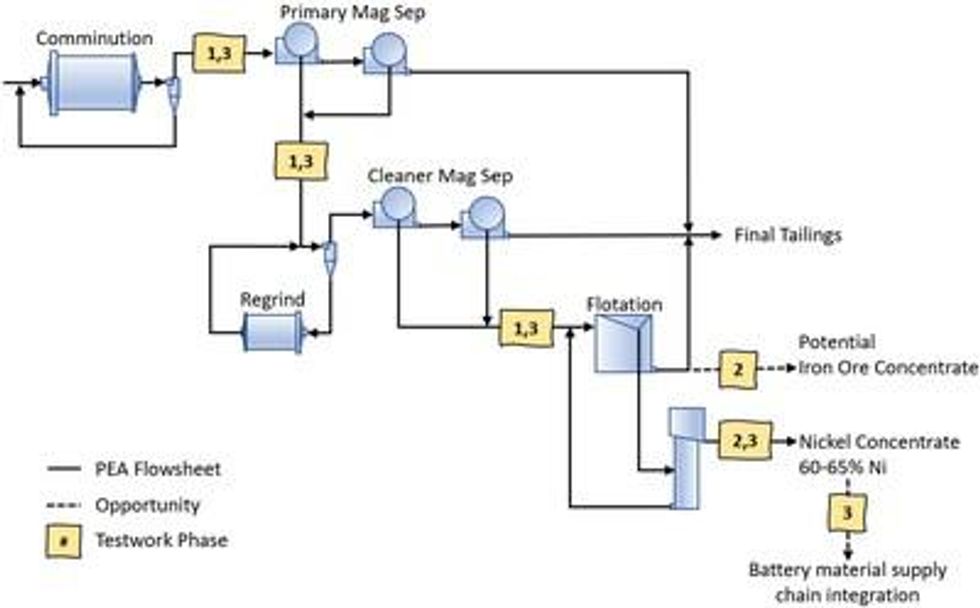

Figure 1 shows the Baptiste nickel recovery flowsheet as presented in the PEA. Highlighted within this figure are the key work elements from the overall three-phase metallurgical program.

Figure 1 – Proposed Flowsheet for Baptiste Nickel Recovery and Upgrading

Phase 1 of the metallurgical testwork program, the results of which are described herein, had the following key objectives:

- Development of robust comminution criteria to define the best value comminution technology

- Validation of the primary magnetic separation grade-recovery relationship to confirm the coarse primary grind size (P 80 of 300 mm) and pre-concentration (rejection of 85% of fresh plant feed in the primary magnetic separation stage)

- Confirming the ability to create a magnetics-only flotation feed to validate the PEA's efficient, modestly-sized, 2-stage flotation process

The objectives of the Phase 2 and 3 metallurgical testwork programs are described in the final section of this news release.

Phase 1 Testwork – Description & Results

Phase 1 of the Baptiste metallurgical testwork program was conducted at several laboratories and overseen by Jeffrey B. Austin , P.Eng., President of International Metallurgical and Environmental Inc. Table 1 presents a summary of the Phase 1 testwork program, including general scope assignment by laboratory.

Table 1 – Phase 1 Metallurgical Test Program Scope Assignments

| Lab | Scope |

| ALS Metallurgy Kamloops, BC | SAG milling and Ball Mill comminution tests |

| UBC Vancouver, BC | HPGR pilot-scale testing |

| Corem Quebec City, QC | HPGR pilot-scale testing |

| SGS Mineral Services Lakefield, ON | Pilot- and bench-scale magnetic separation testing for nickel recovery Sample generation for the Phase 2 metallurgical testwork program |

Comminution Testwork

The Company completed diverse test programs on a variety of representative samples to characterize the performance of Baptiste material under multiple crushing and grinding scenarios. The key takeaways from this testwork include:

- SAG mill testing results indicate consistent, medium-hard material across the deposit, suggesting relatively stable SAG mill throughput

- Ball mill testing results indicate consistent, medium-hard to hard material, with an approximately 10% lower hardness profile in mining phase 1 (first 17 years of mining) versus the later phases of the mine life

- Abrasion testing results indicate consistent, mildly abrasive material, thereby reducing operating consumables

- Test results suggest that SAG milling may emerge as the best value comminution technology for Baptiste, which could lead to lower capital intensity than the HPGR approach in the PEA

Comminution testwork included grindability testwork conducted at ALS Kamloops and pilot-scale HPGR testwork conducted at both UBC and Corem. Grindability testwork utilized six new composite samples representing the PEA's three major mining phases. Pilot-scale HPGR testing at UBC and Corem utilized a newly created life-of-mine master composite created from historic drill core.

SAG Mill Comminution (" SMC ") testwork results confirm the Baptiste material is medium-hard from a SAG milling perspective. Across all phases of the mine life, Axb values are tightly-clustered in the range of 41.4-48.0. Similarly, SAG Circuit Specific Energy (" SCSE ") values are tightly-clustered in the range of 9.1-9.7 kWh/t. There does not appear to be a discernible trend for SMC values throughput the resource, supporting the conclusion that the deposit is largely homogeneous for potential SAG mill throughput.

Ball mill work index testwork results confirm the Baptiste material is medium-hard to hard from a ball milling perspective. Phase 1 material represents the first 17 years of mining and is medium-hard, with tightly-clustered values ranging from 19.6-20.9 kWh/t. Phase 2 material represent the northern extension of the deposit along the resource axis and is harder with values ranging from 22.5-22.9 kWh/t, representing an approximate 10% increase as compared to Phase 1. Phase 3 material is drawn from an area immediately adjacent to the Phase 1 mining area and has a similar hardness value of 20.6 kWh/t.

Abrasion index (" Ai ") testwork results confirm the Baptiste material has low abrasivity. Measured Ai values averaged 0.007, with a maximum value of 0.010. The low abrasion index value is expected to result in comparable operating consumable consumption to other existing large-scale SAG mill circuit processing ultramafic material, which is generally lower than comparably sized porphyry (or similar) operations.

HPGR specific throughput (" m-dot ") values observed in both the UBC and Corem testing were consistent between the two test facilities, peaking at approximately 200 ts/hm 3 . While the measured values are lower than the PEA's assumed specific throughput of 300 ts/hm 3 , they benchmark well with operating values for other ultramafic ores processed by HPGR.

The Company has initiated a comminution trade-off study to evaluate the impact of the new comminution data on project design and project economics. It is anticipated that the Phase 1 results, low cost of power, and low abrasivity will likely see SAG milling emerge as the best value comminution technology for Baptiste, which could lead to lower capital intensity than the HPGR approach in the PEA.

As part of Phase 3, additional comminution testwork will be conducted in 2022 to further expand the comminution database for the Baptiste project, with a particular focus on variability in the first ten years of mining.

Magnetic Separation Testwork

The Company conducted bench- and pilot-scale nickel recovery testwork at SGS Mineral Services in Lakefield , Ontario. The objective of pilot-scale testwork was twofold: to validate bench-scale results and to evaluate potential process improvements which may be realized through plant-scale grinding. In particular, pilot-scale testing was designed to test the view, as described in the PEA, that full-scale operation of a grinding plant, with cyclones for classification, will result in significantly better liberation of dense minerals than what can be achieved at the bench-scale, owing to the manner in which mineral density impacts classification sizes at larger processing scales.

Primary grind and magnetic separation testwork at SGS Lakefield utilized a new 2,400 kg master composite created from crushed assay rejects. The master composite sample graded 0.118% Davis Tube Recoverable (" DTR ") nickel, compared with the life-of-mine average 0.123% DTR Ni grade of the processing feed in the 2020 PEA. Note that DTR is an industry standard measure of quantifying the magnetic mineral content of a sample, and that the nickel mineral awaruite is strongly magnetic and readily recoverable in a magnetic separator. Total nickel grades for the Baptiste resource are consistently in the range of 0.20-0.23% total nickel.

Bench-Scale Magnetic Separation Testwork

Table 2 provides a summary of primary magnetic separation testing results at a variety of grind sizes in comparison to the criteria established in the 2020 PEA.

Table 2 – Bench-Scale Magnetic Separation Test Program Results

| | Grind Size, P 80 (mm) | Recovery, DTR Ni (%) |

| PEA Criteria | 300 | 90.0 |

| 2021 Met Program, Bench-Scale | 152 | 94.5 |

| 327 | 88.6 | |

| 491 | 87.0 |

These 2021 bench-scale results have confirmed key PEA recovery criteria. This is an important result, particularly considering the PEA criteria were based on the 2017/18 metallurgical testwork program which utilized a composite which had a 0.158% DTR Ni grade, while this 2021 testing utilized the new master composite which has a 0.118% DTR Ni grade (approximately 25% lower).

At the same time, mass pulls and concentrate grades were higher and lower than PEA criteria, respectively. This is likely due to selectively issues owing to lower-than-optimal magnetic separator feed rates during bench-scale testing. As such, increased focus was applied to magnetic separator operating conditions during subsequent pilot-scale testing (see below).

Pilot-Scale Magnetic Separation Testwork

Pilot-scale testing was conducted to evaluate the upside recovery potential posed by cyclone classification through preferential grinding of the dense minerals, including awaruite (specific gravity of 7.3) and magnetite (specific gravity of 5.4). Preferential grinding of dense minerals in cyclone classification is common in several mineral processing operations, including gold, lead, copper and iron operations.

Two pilot-scale runs were conducted using cyclone classification in a standard grinding circuit configuration. These pilot-scale test results showed reduced tailings losses for nickel when materials are classified with a cyclone. The use of cyclone classification also demonstrated that circulation of dense minerals leads to a build-up of magnetite and awaruite within the milling circuit. This confounded overall metal accounting for the pilot-scale test run durations; however, it is anticipated that the longer and higher throughput pilot-scale test runs planned for Phase 3 of the metallurgical program will resolve this challenge. A single pilot plant test was also performed using a classifying screen in place of the cyclone to provide comparison results.

Key results from pilot scale testing are presented in Table 3 below, including data for pilot operation with classification by cyclone and screen.

Table 3 – Pilot-Scale Magnetic Separation Test Program Results

| Testing Method | Classification | Grind Size, | Mass | Tail Grade, | Recovery, |

| PEA Criteria | n/a (batch ground) | 300 | 15 | 0.010 | 90.0 |

| 2021 Met Program, Pilot-Scale | Cyclone | 245 | 13.2 | 0.005 | 96.3 |

| Cyclone | 133 | 15.8 | 0.006 | 95.7 | |

| Screen | 256 | 17.5 | 0.007 | 95.1 |

The observed differences in tailings grades when using different methods of feed preparation was expected based on past experience and the observed mineralogical composition of the Baptiste deposit. Comparing the calculated recoveries in pilot-scale testwork as compared to PEA recovery criteria, it is likely that nickel recovery in bench-scale testwork underestimated the full-scale recovery potential by up to 5% of DTR nickel.

With improved magnetic separator operating conditions, mass pulls aligned with PEA criteria, at approximately 15%. This result, in tandem with the lower tailings grade during the pilot-scale tests, suggests the potential to achieve similar mass pulls and concentrate grades as those assumed in the PEA.

Building on these positive pilot plant results, additional pilot-scale testwork will be conducted in Phase 3 of the metallurgical testwork program. This testwork will utilize higher throughput rates and longer durations to ensure steady state, repeatable conditions are realized. In tandem with a bench-scale variability program, validation of the favourable pilot-scale results should confirm an improved DTR recovery basis for use in a PFS for the Project.

Regrind & Cleaner Magnetic Separation Testwork

As noted in the PEA, and as demonstrated in bench-scale testwork conducted in 2017-18, regrinding of the primary magnetic separation concentrate and additional magnetic separation upgrading can produce a high-grade concentrate of magnetite and awaruite. This serves as an ideal feed to the two-stage separation flotation process as presented in the PEA.

Approximately 60 kilograms of high-grade magnetic concentrate was produced for use in detailed flotation testwork at SGS Mineral Services in Burnaby , B.C. This concentrate graded approximately 2.2% nickel and 54% iron, which is comparable to samples used for the PEA's flotation testwork.

While the use of cyclone classification indicates increased nickel recovery, it will also likely alter the mineralogical characteristics of the primary magnetic separation concentrate and the subsequent regrind requirements for upgrading magnetite and awaruite. Investigative testwork has shown that recovery of more fine awaruite-containing material requires finer regrinding to maintain the high-grade nature of the magnetic concentrate prior to flotation.

As described below, Phase 3 testwork will better define the regrind requirements during larger-scale pilot testing. During this testing, it is anticipated the same preferential classification witnessed in pilot-scale primary grinding will similarly prove beneficial to regrind requirements.

Phase 2 Testwork

Phase 2 of the metallurgical testwork program commenced in November, and it is expected that results will be reported in the first quarter of 2022. Phase 2 will focus on:

- Confirming the production of a high-grade nickel concentrate by froth flotation. The initial flotation tests will focus on validating PEA criteria, followed by subsequent flotation tests to optimize flotation conditions

- Evaluating the potential for producing a saleable iron ore concentrate, which represents a potential new product stream which was not included in the 2020 PEA

Phase 3 Testwork

Phase 3 of the metallurgical testwork program is scheduled to commence in December, and it is expected that results will be reported in the third quarter of 2022. Phase 3 will focus on:

- Confirming Phase 1 recovery opportunities through larger-scale pilot testing, for both primary grind and magnetic separation, as well as regrind and cleaner magnetic separation

- Demonstrating a robust and efficient integration into the battery material supply chain by optimizing previous leach testwork and conducting solvent extraction and NiSO 4 crystallization testwork

- Conducting suitable variability testwork with a focus on the first 10 years of mining, confirming Baptiste homogeneity and informing PFS criteria and design factors

Qualified Person

The metallurgical information in this news release has been prepared in accordance with Canadian regulatory requirements set our in National Instrument 43-101 Standards of Disclosures for Minerals Projects of the Canadian Securities Administrators (" NI 43-101 ") and supervised, reviewed, and verified by Jeffrey B. Austin , P.Eng., President of International Metallurgical and Environmental Inc., a "Qualified Person" as defined by NI 43-101 and the person who oversees metallurgical developments for FPX Nickel.

About the Decar Nickel District

The Company's Decar Nickel District claims cover 245 km 2 of the Mount Sidney Williams ultramafic/ophiolite complex, 90 km northwest of Fort St. James in central British Columbia . The District is a two-hour drive from Fort St. James on a high-speed logging road.

Decar hosts a greenfield discovery of nickel mineralization in the form of a naturally occurring nickel-iron alloy called awaruite (Ni 3 Fe), which is amenable to bulk-tonnage, open-pit mining. Awaruite mineralization has been identified in four target areas within this ophiolite complex, being the Baptiste Deposit, and the B, Sid and Van targets, as confirmed by drilling in the first three plus petrographic examination, electron probe analyses and outcrop sampling on all four. Since 2010, approximately US $28 million has been spent on the exploration and development of Decar.

Of the four targets in the Decar Nickel District, the Baptiste Deposit, which was initially the most accessible and had the biggest known surface footprint, has been the focus of diamond drilling since 2010, with a total of 82 holes and over 31,000 m of drilling completed. The Sid target was tested with two holes in 2010 and the B target had a single hole drilled in 2011; all three holes intersected nickel-iron alloy mineralization over wide intervals with DTR nickel grades comparable to the Baptiste Deposit. The Van target was not drill-tested at that time as bedrock exposures in the area were very poor prior to more recent logging activity.

In 2021, the Company executed a very successful maiden drilling program at Van, which has returned promising results comparable with the strongest results at Baptiste.

About FPX Nickel Corp.

FPX Nickel Corp. is focused on the exploration and development of the Decar Nickel District, located in central British Columbia , and other occurrences of the same unique style of naturally occurring nickel-iron alloy mineralization known as awaruite.

On behalf of FPX Nickel Corp.

"Martin Turenne"

Martin Turenne , President, CEO and Director

Forward-Looking Statements

Certain of the statements made and information contained herein is considered "forward-looking information" within the meaning of applicable Canadian securities laws. These statements address future events and conditions and so involve inherent risks and uncertainties, as disclosed in the Company's periodic filings with Canadian securities regulators. Actual results could differ from those currently projected. The Company does not assume the obligation to update any forward-looking statement.

Neither the TSX Venture Exchange nor its Regulation Services Provider accepts responsibility for the adequacy or accuracy of this release.

SOURCE FPX Nickel Corp.