Forsys Metals Corp. (TSX: FSY) (FSE: F2T) (NSX: FSY) ("Forsys" or the "Company")

Forsys is pleased to provide assay results from the Valencia 2023 drilling programme, from Mining License ("ML)-149("Valencia") in the Erongo region of Namibia, which forms part of the Company's larger Norasa Uranium Project ("Norasa¹").

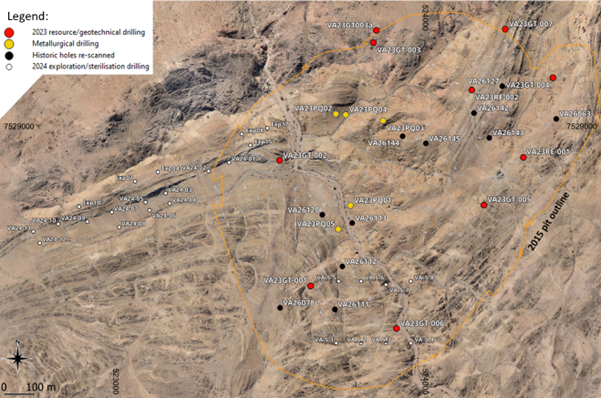

Fifteen boreholes were drilled with a combined total of 2,684.44 metres ("m") (Figure 1). The objectives of the drill program were:

- geotechnical drilling, and logging and sampling for geo-mechanical testing for pit slope stability assessment and optimizing pit designs;

- testing the continuity of mineralization for resource modelling;

- confirming Mineral Resource Estimation (MRE) parameters; and

- sampling for metallurgical test work and processing design optimization

Drilling, geological and geotechnical logging, down-hole optical televiewer and radiometric scans have been completed on the 15 holes. Eight hundred and nineteen samples from ten of the boreholes underwent assay with established quality control protocol and procedures. The chemical results have been verified by an accredited lab and reviewed by a third party professional geologist. Highlights are as follows:

- Multiple zones of massive alaskite intrusions were intersected. Chemical assays confirm uranium mineralization in all six of the confirmation boreholes.

- Best mineralized borehole PQ-5 intersected 77.34 m of continuous mineralisation, averaging 439 ppm U 3 O 8 , including 41.9 m of 683 ppm U 3 O 8 .

- 2023 intersections of mineralization correlate with the neighbouring, historic drilling, intersections and down-hole gamma survey results.

- No major zones of rock weakness, i.e. no concerning geological structures, have been intersected. This is a positive result for the ongoing geotechnical specialist work, as it indicates conducive conditions for pit slope optimization and overall mine design.

Table 1: Highlights reported from the completed 2023 drill campaign, minimum width of 5m and cutoff of 50 ppm U 3 O 8

| BHID | FROM m | TO m | LENGTH m | U3O8 ppm | FROM m | TO m | LENGTH m | U3O8 ppm | |

| VA23GT001 | 23 | 29 | 6 | 108 | |||||

| VA23GT001 | 40 | 47 | 7 | 189 | |||||

| VA23GT001 | 77 | 82 | 5 | 66 | |||||

| VA23GT001 | 95 | 101 | 6 | 140 | |||||

| VA23GT002 | 38 | 77 | 39 | 106 | |||||

| VA23GT002 | 105.3 | 149 | 43.7 | 152 | including | 104 | 124.1 | 20.1 | 334 |

| VA23GT004 | 1 | 103.2 | 102.2 | 164 | including | 73 | 103.2 | 30.2 | 216 |

| VA23GT005 | 22 | 41 | 19 | 92 | |||||

| VA23GT005 | 51 | 63 | 12 | 218 | |||||

| VA23GT005 | 89 | 94 | 5 | 123 | |||||

| VA23GT005 | 101 | 106 | 5 | 114 | |||||

| VA23GT005 | 116.2 | 129 | 12.8 | 122 | |||||

| VA23GT005 | 141.8 | 147.11 | 5.31 | 241 | |||||

| VA23GT005 | 229.13 | 239 | 9.87 | 236 | |||||

| VA23GT005 | 244.77 | 272 | 27.23 | 184 | |||||

| VA23GT006 | 65 | 81 | 16 | 136 | |||||

| VA23GT006 | 100 | 105 | 5 | 143 | |||||

| VA23GT007 | 18 | 26 | 8 | 194 | |||||

| VA23GT007 | 33 | 38 | 5 | 194 | |||||

| VA23GT007 | 189 | 195 | 6 | 213 | |||||

| VA23PQ04 | 30 | 37.5 | 7.5 | 229 | |||||

| VA23PQ04 | 54 | 59 | 5 | 181 | |||||

| VA23PQ05 | 3.96 | 81.3 | 77.34 | 439 | including | 36 | 77.9 | 41.9 | 683 |

| VA23RE001 | 50 | 100 | 50 | 90 | |||||

| VA23RE001 | 114 | 119 | 5 | 215 | |||||

| VA23RE001 | 128.73 | 178 | 49.27 | 201 | including | 142 | 169.05 | 27.05 | 275 |

| VA23RE001 | 190 | 237 | 47 | 253 | including | 202.37 | 225 | 22.63 | 371 |

| VA23RE001 | 302.75 | 414 | 111.25 | 134 | including | 322.88 | 345.24 | 22.36 | 331 |

| VA23RE002 | 1 | 21 | 20 | 105 | |||||

| VA23RE002 | 95 | 124.1 | 29.1 | 271 | including | 104 | 124.1 | 20.1 | 334 |

| VA23RE002 | 129.7 | 152 | 22.3 | 376 | including | 129.7 | 140.8 | 11.1 | 673 |

| VA23RE002 | 160 | 180 | 20 | 162 | |||||

| VA23RE002 | 244 | 251.2 | 7.2 | 158 | |||||

| VA23RE002 | 258 | 268 | 10 | 171 | |||||

| VA23RE002 | 275 | 288 | 13 | 139 |

Geological context:

- Boreholes GT-01 to GT-07 were drilled from within the planned Valencia Main mine pit, angled and directed away from the centre of the 2015 pit shell to investigate the ground conditions for the pit slope design.

- Two boreholes, RE-01 and RE-02, were strategically positioned to confirm mineralization from the 2015 FS Mineral Resource Estimate at Valencia in a geologically unique zone.

- Holes PQ-01 to PQ-05 were drilled at Valencia for a total of 285.31 m, providing approximately 3 tons of sample for metallurgical testing.

Figure 1: Recent boreholes drilled within the 2015 main pit outline on ML-149, Valencia West planned exploration drilling.

https://www.globenewswire.com/NewsRoom/AttachmentNg/bdc97a7e-8ff7-4fa6-8c7e-6a71aa561a7d

Borehole samples were selected for geochemical assay from the routine downhole radiometric scanning results and sent to Trace Elements Analysis Laboratories (Pty) Ltd ("TEA Labs") in Swakopmund for sample preparation and analyses by XRF. For internal quality control purposes TEA Labs has weekly round robins with independent laboratories at Rosh Pinah, Husab Uranium, and Langer Heinrich mine laboratories.

Forsys employs an industry standard QA/QC program with Standard Reference Materials, blanks, coarse duplicates and pulp duplicates inserted into each batch of samples analysed. 4% of the samples sent to TEA Labs were sent for check analyses to SGS Laboratories in South Africa, which is an independent accredited laboratory. The sample results are further validated by comparison with the downhole radiometric survey results.

Table-2 below lists borehole intersections with minimum intersections of 50ppm U 3 O 8 over 5m:

Table 2: 2023 drill campaign: drill type, assay, composites, downhole gamma survey

| BHID | X | Y | Z | FROM | TO | LENGT H | EOH | RC | COR E | Gamm a | U | Th | U3O 8 |

| UTM | UTM | m amsl | m | m | m | m | m | m | cps | pp m | pp m | p pm | |

| VA23GT001 | 523609 | 7528504 | 716.505 | 0 | 23 | 23 | 222 | - | 222 | - | - | - | 0 |

| VA23GT001 | 523602 | 7528501 | 703.981 | 23 | 29 | 6 | 222 | - | 222 | 722 | 92 | - | 108 |

| VA23GT001 | 523598 | 7528499 | 696.608 | 29 | 40 | 11 | 222 | - | 222 | 308 | - | - | 0 |

| VA23GT001 | 523594 | 7528498 | 688.796 | 40 | 47 | 7 | 222 | - | 222 | 702 | 160 | - | 189 |

| VA23GT001 | 523586 | 7528494 | 672.673 | 47 | 77 | 30 | 222 | - | 222 | 235 | - | - | 0 |

| VA23GT001 | 523578 | 7528490 | 657.402 | 77 | 82 | 5 | 222 | - | 222 | 761 | 55 | - | 66 |

| VA23GT001 | 523574 | 7528489 | 649.543 | 82 | 95 | 13 | 222 | - | 222 | 204 | - | - | 0 |

| VA23GT001 | 523570 | 7528487 | 641.25 | 95 | 101 | 6 | 222 | - | 222 | - | 119 | - | 140 |

| VA23GT001 | 523541 | 7528475 | 585.825 | 101 | 222 | 121 | 222 | - | 222 | - | - | - | 0 |

| VA23GT002 | 523526 | 7528889 | 697.146 | 0 | 38 | 38 | 203.8 | 102 | 100 | 108 | - | - | 0 |

| VA23GT002 | 523518 | 7528896 | 660.245 | 38 | 77 | 39 | 203.8 | 102 | 100 | 495 | 90 | - | 106 |

| VA23GT002 | 523510 | 7528904 | 628.372 | 77 | 105.3 | 28.3 | 203.8 | 102 | 100 | 201 | - | - | 2 |

| VA23GT002 | 523502 | 7528914 | 594.818 | 105.3 | 149 | 43.7 | 203.8 | 102 | 100 | 744 | 129 | 36 | 152 |

| VA23GT002 | 523496 | 7528926 | 561.152 | 149 | 177.95 | 28.95 | 203.8 | 102 | 100 | 214 | - | - | 1 |

| VA23GT002 | 523491 | 7528936 | 533.545 | 184 | 202.8 | 18.8 | 203.8 | 102 | 100 | 216 | - | - | 0 |

| VA23GT003 | 523841 | 7529328 | 692.427 | 0 | 102 | 102 | 102 | 102 | - | - | - | - | 0 |

| VA23GT003 | 523861 | 7529274 | 633.213 | 0 | 227.28 | 227.28 | 227.28 | - | 225 | 186 | - | - | 0 |

| VA23GT004 | 524440 | 7529153 | 734.567 | 0 | 1 | 1 | 152.26 | 50.26 | 102 | - | - | - | 0 |

| VA23GT004 | 524467 | 7529148 | 690.761 | 1 | 103.2 | 102.2 | 152.26 | 50.26 | 102 | 1134 | 139 | - | 164 |

| VA23GT004 | 524507 | 7529140 | 627.146 | 103.2 | 152.26 | 49.06 | 152.26 | 50.26 | 102 | 150 | - | - | 1 |

| VA23GT005 | 524189 | 7528751 | 729.233 | 0 | 22 | 22 | 275.47 | 102 | 173 | - | - | - | 0 |

| VA23GT005 | 524187 | 7528755 | 709.298 | 22 | 41 | 19 | 275.47 | 102 | 173 | 421 | 78 | - | 92 |

| VA23GT005 | 524185 | 7528759 | 695.341 | 41 | 51 | 10 | 275.47 | 102 | 173 | 265 | - | - | 0 |

| VA23GT005 | 524184 | 7528762 | 684.832 | 51 | 63 | 12 | 275.47 | 102 | 173 | 1185 | 185 | - | 218 |

| VA23GT005 | 524181 | 7528767 | 667.017 | 63 | 89 | 26 | 275.47 | 102 | 173 | 252 | - | - | 0 |

| VA23GT005 | 524178 | 7528773 | 652.66 | 89 | 94 | 5 | 275.47 | 102 | 173 | 496 | 104 | - | 123 |

| VA23GT005 | 524177 | 7528775 | 647.267 | 94 | 101 | 7 | 275.47 | 102 | 173 | 178 | - | - | 0 |

| VA23GT005 | 524176 | 7528777 | 641.914 | 101 | 106 | 5 | 275.47 | 102 | 173 | 574 | - | - | 114 |

| VA23GT005 | 524174 | 7528781 | 635.168 | 106 | 116.2 | 10.2 | 275.47 | 102 | 173 | 162 | - | - | 0 |

| VA23GT005 | 524172 | 7528786 | 624.989 | 116.2 | 129 | 12.8 | 275.47 | 102 | 173 | 653 | - | - | 122 |

| VA23GT005 | 524170 | 7528791 | 613.699 | 129 | 141.8 | 12.8 | 275.47 | 102 | 173 | 277 | - | - | 9 |

| VA23GT005 | 524168 | 7528795 | 605.732 | 141.8 | 147.11 | 5.31 | 275.47 | 102 | 173 | 1282 | 205 | 7 | 241 |

| VA23GT005 | 524159 | 7528815 | 567.876 | 147.11 | 229.13 | 82.02 | 275.47 | 102 | 173 | 180 | - | - | 0 |

| VA23GT005 | 524150 | 7528836 | 528.09 | 229.13 | 239 | 9.87 | 275.47 | 102 | 173 | 1394 | 200 | 25 | 236 |

| VA23GT005 | 524148 | 7528840 | 521.336 | 239 | 244.77 | 5.77 | 275.47 | 102 | 173 | 142 | - | - | 0 |

| VA23GT005 | 524145 | 7528847 | 507.084 | 244.77 | 272 | 27.23 | 275.47 | 102 | 173 | 977 | 156 | 51 | 184 |

| VA23GT005 | 524142 | 7528854 | 493.825 | 272 | 275.47 | 3.47 | 275.47 | 102 | 173 | - | - | - | 0 |

| VA23GT006 | 523928 | 7528337 | 693.644 | 0 | 65 | 65 | 225.14 | 100 | 125 | 251 | - | - | 0 |

| VA23GT006 | 523936 | 7528330 | 654.546 | 65 | 81 | 16 | 225.14 | 100 | 125 | 504 | 115 | - | 136 |

| VA23GT006 | 523940 | 7528328 | 637.595 | 81 | 100 | 19 | 225.14 | 100 | 125 | 312 | - | - | 0 |

| VA23GT006 | 523943 | 7528327 | 625.965 | 100 | 105 | 5 | 225.14 | 100 | 125 | 734 | 121 | 28 | 143 |

| VA23GT006 | 523957 | 7528323 | 566.26 | 105 | 223.14 | 118.14 | 225.14 | 100 | 125 | 242 | - | - | 0 |

| VA23GT007 | 524262 | 7529312 | 734.236 | 0 | 18 | 18 | 275.35 | 102 | 168 | - | - | - | 0 |

| VA23GT007 | 524257 | 7529316 | 723.059 | 18 | 26 | 8 | 275.35 | 102 | 168 | 1141 | 164 | - | 194 |

| VA23GT007 | 524254 | 7529318 | 716.725 | 26 | 33 | 7 | 275.35 | 102 | 168 | 350 | - | - | 0 |

| VA23GT007 | 524251 | 7529320 | 711.742 | 33 | 38 | 5 | 275.35 | 102 | 168 | 515 | 165 | - | 194 |

| VA23GT007 | 524217 | 7529357 | 652.171 | 38 | 189 | 151 | 275.35 | 102 | 168 | 281 | - | - | 0 |

| VA23GT007 | 524182 | 7529394 | 592.48 | 189 | 195 | 6 | 275.35 | 102 | 168 | 773 | 180 | 5 | 213 |

| VA23GT007 | 524162 | 7529417 | 561.769 | 195 | 275.35 | 80.35 | 275.35 | 102 | 168 | - | - | - | 0 |

| VA23PQ01 | 523762 | 7528744 | 688.025 | 0 | 59.95 | 59.95 | 60 | - | 59.95 | 892 | - | - | 0 |

| VA23PQ02 | 523714 | 7529040 | 709.151 | 0 | 23.7 | 23.7 | 23.7 | - | 23.7 | - | - | - | 0 |

| VA23PQ03 | 523869 | 7529019 | 702.407 | 0 | 61.27 | 61.27 | 60.27 | - | 60.27 | - | - | - | 0 |

| VA23PQ04 | 523745 | 7529037 | 702.033 | 0 | 30 | 30 | 59 | - | 59 | 291 | - | - | 0 |

| VA23PQ04 | 523744 | 7529037 | 683.329 | 30 | 37.5 | 7.5 | 59 | - | 59 | 1230 | 194 | 46 | 229 |

| VA23PQ04 | 523743 | 7529038 | 671.361 | 37.5 | 54 | 16.5 | 59 | - | 59 | 258 | - | - | 0 |

| VA23PQ04 | 523743 | 7529038 | 660.637 | 54 | 59 | 5 | 59 | - | 59 | 1019 | - | - | 181 |

| VA23PQ05 | 523722 | 7528668 | 721.02 | 0 | 3.96 | 3.96 | 80 | - | 80 | - | - | - | 0 |

| VA23PQ05 | 523722 | 7528668 | 680.372 | 3.96 | 81.3 | 77.34 | 80 | - | 80 | 3138 | 372 | 48 | 439 |

| VA23RE001 | 524309 | 7528910 | 724.265 | 0 | 50 | 50 | 419.72 | 102 | 318 | 512 | - | - | 0 |

| VA23RE001 | 524286 | 7528933 | 686.478 | 50 | 100 | 50 | 419.72 | 102 | 318 | 375 | 76 | - | 90 |

| VA23RE001 | 524270 | 7528949 | 663.893 | 100 | 114 | 14 | 419.72 | 102 | 318 | 121 | - | - | 5 |

| VA23RE001 | 524265 | 7528954 | 657.753 | 114 | 119 | 5 | 419.72 | 102 | 318 | 1319 | 190 | - | 215 |

| VA23RE001 | 524261 | 7528958 | 653.019 | 119 | 128.73 | 9.73 | 419.72 | 102 | 318 | 85 | - | - | 0 |

| VA23RE001 | 524244 | 7528974 | 634.211 | 128.73 | 178 | 49.27 | 419.72 | 102 | 318 | 1266 | - | - | 201 |

| VA23RE001 | 524227 | 7528991 | 614.788 | 178 | 190 | 12 | 419.72 | 102 | 318 | 156 | - | - | 0 |

| VA23RE001 | 524210 | 7529007 | 596.799 | 190 | 237 | 47 | 419.72 | 102 | 318 | 1892 | 215 | - | 253 |

| VA23RE001 | 524178 | 7529038 | 563.102 | 237 | 302.75 | 65.75 | 419.72 | 102 | 318 | 83 | - | - | 1 |

| VA23RE001 | 524127 | 7529089 | 511.66 | 302.75 | 414 | 111.25 | 419.72 | 102 | 318 | - | - | - | 134 |

| VA23RE001 | 524093 | 7529123 | 478.027 | 414 | 419.72 | 5.72 | 419.72 | 102 | 318 | 2 | 39 | - | 47 |

| VA23RE002 | 524153 | 7529118 | 748.623 | 0 | 1 | 1 | 296.21 | 102 | 153 | - | - | - | 0 |

| VA23RE002 | 524159 | 7529114 | 740.728 | 1 | 21 | 20 | 296.21 | 102 | 153 | 671 | 89 | - | 105 |

| VA23RE002 | 524186 | 7529096 | 706.86 | 21 | 95 | 74 | 296.21 | 102 | 153 | 107 | 15 | - | 18 |

| VA23RE002 | 524217 | 7529075 | 670.879 | 95 | 124.1 | 29.1 | 296.21 | 102 | 153 | 1980 | 229 | - | 271 |

| VA23RE002 | 524228 | 7529068 | 659.428 | 124.1 | 129.7 | 5.6 | 296.21 | 102 | 153 | 330 | 15 | - | 17 |

| VA23RE002 | 524237 | 7529063 | 650.437 | 129.7 | 152 | 22.3 | 296.21 | 102 | 153 | 2767 | 318 | - | 376 |

| VA23RE002 | 524247 | 7529057 | 640.726 | 152 | 160 | 8 | 296.21 | 102 | 153 | 200 | - | - | 0 |

| VA23RE002 | 524256 | 7529051 | 631.919 | 160 | 180 | 20 | 296.21 | 102 | 153 | 1046 | 137 | - | 162 |

| VA23RE002 | 524285 | 7529034 | 606.377 | 180 | 244 | 64 | 296.21 | 102 | 153 | 130 | - | - | 0 |

| VA23RE002 | 524309 | 7529019 | 585.009 | 244 | 251.2 | 7.2 | 296.21 | 102 | 153 | 1021 | 134 | - | 158 |

| VA23RE002 | 524314 | 7529016 | 580.956 | 251.2 | 258 | 6.8 | 296.21 | 102 | 153 | 613 | - | - | 12 |

| VA23RE002 | 524319 | 7529012 | 576.141 | 258 | 268 | 10 | 296.21 | 102 | 153 | 1370 | 145 | - | 171 |

| VA23RE002 | 524325 | 7529008 | 571.309 | 268 | 275 | 7 | 296.21 | 102 | 153 | 380 | - | - | 0 |

| VA23RE002 | 524332 | 7529004 | 565.685 | 275 | 288 | 13 | 296.21 | 102 | 153 | 786 | 118 | - | 139 |

| VA23RE002 | 524339 | 7528999 | 559.753 | 288 | 296.21 | 8.21 | 296.21 | 102 | 153 | - | - | - | 0 |

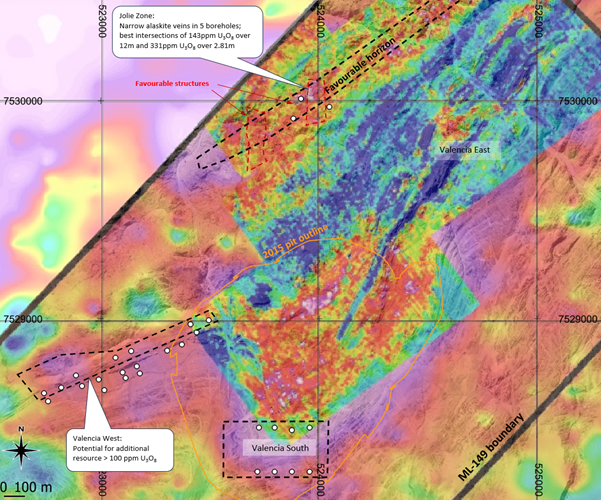

2024 Drilling Program on ML-149, Valencia

The Company also announces that it has commenced a new drilling program at Valencia. Three zones of potential uranium mineralization situated outside of the existing resource block model are now being investigated.

The drilling program focusses on three target areas; refer to Table-3 and Figure-2 for individual drill hole locations:

- A favourable horizon identified at the Jolie Zone (~ 1km north of Valencia pit)

- Valencia West Extension

- Valencia South

Twenty-nine boreholes are scheduled for a total of 5,236m of drilling to assess mineralization to depths of up to 380 m below collar.

The three areas of mineralization potential were delineated from historic exploration work that included; aerial photo interpretation, geological mapping, aeromagnetic surveys, airborne and ground scintillometer surveys and exploration drilling. Investigation by drilling is required to define the mine's surface infrastructure development and also to explore for resource upside potential in these areas.

Table 3: Below lists the holes planned for RC drilling. A diamond drill rig is available for extension of the RC drill section, as required by the ground conditions.

| BHID | Rig / Ranking | X COLLAR | Y COLLAR | Z COLLAR | EOH | BRG | DIP |

| UTM | UTM | m | m | degree | degree | ||

| VA24-01 | VA_West | 523370 | 7528883 | 724 | 150 | 330 | 60 |

| VA24-02 | VA_West | 523303 | 7528855 | 725 | 132 | 330 | 60 |

| VA24-03 | VA_West | 523165 | 7528783 | 729 | 126 | 330 | 60 |

| VA24-04 | VA_West | 523178 | 7528750 | 721 | 150 | 330 | 60 |

| VA24-05 | VA_West | 523100 | 7528754 | 731 | 144 | 330 | 60 |

| VA24-06 | VA_West | 523113 | 7528729 | 726 | 180 | 330 | 70 |

| VA24-07 | VA_West | 522990 | 7528722 | 735 | 98 | 330 | 60 |

| VA24-08 | VA_West | 523015 | 7528674 | 727 | 132 | 330 | 60 |

| VA24-09 | VA_West | 522912 | 7528692 | 735 | 168 | 330 | 60 |

| VA24-10 | VA_West | 522818 | 7528684 | 736 | 120 | 330 | 60 |

| Exp13 | VA_West | 522738 | 7528660 | 741 | 98 | 330 | 60 |

| Exp14 | VA_West | 522763 | 7528616 | 734 | 172 | 330 | 60 |

| Exp15 | VA_West | 523439 | 7528939 | 730 | 138 | 340 | 60 |

| Exp04 | VA_West | 523139 | 7528852 | 743 | 84 | 330 | 61 |

| Exp07 | VA_West | 523066 | 7528822 | 743 | 72 | 330 | 60 |

| Exp10 | VA_West | 522885 | 7528741 | 750 | 120 | 330 | 60 |

| Exp08 | VA_West | 523411 | 7528974 | 724 | 78 | 330 | 60 |

| Exp17 | VA_West | 523493 | 7528994 | 721 | 98 | 330 | 60 |

| Jolie01 | Jolie | 523883 | 7529918 | 680 | 120 | 330 | 60 |

| Jolie02 | Jolie | 523917 | 7530008 | 694 | 66 | 330 | 60 |

| Jolie03 | Jolie | 524046 | 7529973 | 705 | 150 | 330 | 60 |

| VA_S_1 | VA_South | 523716 | 7528300 | 725 | 260 | 270 | 60 |

| VA_S_2 | VA_South | 523796 | 7528300 | 725 | 300 | 270 | 60 |

| VA_S_3 | VA_South | 523876 | 7528300 | 725 | 360 | 270 | 60 |

| VA_S_4 | VA_South | 523956 | 7528300 | 725 | 380 | 270 | 60 |

| VA_S_5 | VA_South | 523723 | 7528500 | 725 | 260 | 270 | 60 |

| VA_S_6 | VA_South | 523796 | 7528500 | 735 | 320 | 270 | 60 |

| VA_S_7 | VA_South | 523876 | 7528489 | 725 | 380 | 270 | 60 |

| VA_S_8 | VA_South | 523956 | 7528500 | 732 | 380 | 270 | 60 |

| Total metres: | 5,236 | ||||||

Boreholes VA24-01 to VA10 are completed, awaiting down-hole surveys, detailed recording, and sampling for chemical assay. Additional drilling might be required to test at depth, dependent onthe results to be obtained from the campaign.

Figure 2: Overview map of Norasa 2024 Q1 drill campaign on a radiometric background.

https://www.globenewswire.com/NewsRoom/AttachmentNg/38b9bda9-00f8-4a9f-b9db-85c1beade129

Qualified Persons Statement

The information in this release that relates to "project update" for the Norasa Project is based on information compiled or reviewed by Dr Guy Freemantle of The MSA Group (Pty) Ltd., South Africa. Dr Freemantle is a consultant for Valencia Uranium (Pty) Ltd. and is a member of the SACNASP. Dr Freemantle has sufficient experience and knowledge that is relevant to the style of mineralisation and type of deposits under consideration as well as to the activity that is being undertaken to fulfill requirements of a Qualified Person as per NI 43-101. Dr Freemantle consents to this release in the form and context in which it appears.

About Forsys Metals Corp.

Forsys Metals Corp. (TSX: FSY, FSE: F2T, NSX: FSY) is an emerging uranium developer focused on advancing its wholly-owned Norasa Uranium Project, located in the politically friendly jurisdiction of Namibia, Africa. The Norasa Uranium Project is comprised of the Valencia Uranium deposit (ML-149) and the nearby Namibplaas Uranium deposit (EPL-3638).

Further information is available at the Company website www.forsysmetals.com .

On behalf of the Board of Directors of Forsys Metals Corp. Richard Parkhouse, Director, Investor Relations.

For additional information please contact:

Richard Parkhouse, Director, Investor Relations

email: rparhkhouse@forsysmetals.com email: info@forsysmetals.com

Forward-Looking Statement

Certain information contained in this press release constitutes "forward-looking information" , within the meaning of Canadian legislation. Generally, these forward-looking statements can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur", "be achieved" or "has the potential to". Forward looking statements contained in this press release are qualified in their entirety by the inherent risks and uncertainties surrounding future expectations. Among those factors which could cause actual results to differ materially are the following: market conditions and other risk factors listed from time to time in our reports filed with Canadian securities regulators on SEDAR at www.sedarplus.ca . The forward-looking statements included in this press release are made as of the date of this press release and Forsys Metals Corp disclaim any intention or obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as expressly required by applicable securities legislation.

_____________________________

¹ The Norasa Uranium Project ("Norasa") is wholly-owned by the Company's 100% subsidiary Valencia Uranium (Pty) Ltd. ("Valencia Uranium") and comprises the Valencia uranium deposits (held under ML-149) ("Valencia") and the Namibplaas uranium deposit (under EPL-3638, application for ML-251) ("Nambiplaas").