- WORLD EDITIONAustraliaNorth AmericaWorld

August 17, 2022

ChemX Materials Ltd (ASX:CMX) (ChemX or the Company), a materials technology company focused on the electrification and decarbonisation markets, is pleased to confirm that it will build a High Purity Alumina (HPA) Pilot Plant after a Pre-feasibility Study (PFS) confirmed the viability of the company’s proprietary HiPurA® technology.

Highlights

Pre-feasibility Study

- HiPurA® High Purity Alumina (HPA) Pre-Feasibility Study (PFS) confirms Flow Sheet Design with no fatal flaws identified

- PFS highlights the low Capex intensity of the technology

˗ Construction cost A$2.5 million for 50tpa HPA Pilot Plant

- Significantly lower Capital Costs than incumbent HPA technologies

- HiPurA® Vendor Stage 2 Performance Payment to Proceed HiPurA® HPA Micro-plant

- HPA Micro-plant successfully commissioned

- Initial HPA material from micro-plant production to be analysed for purity

- Initial Mass and Energy Balances completed

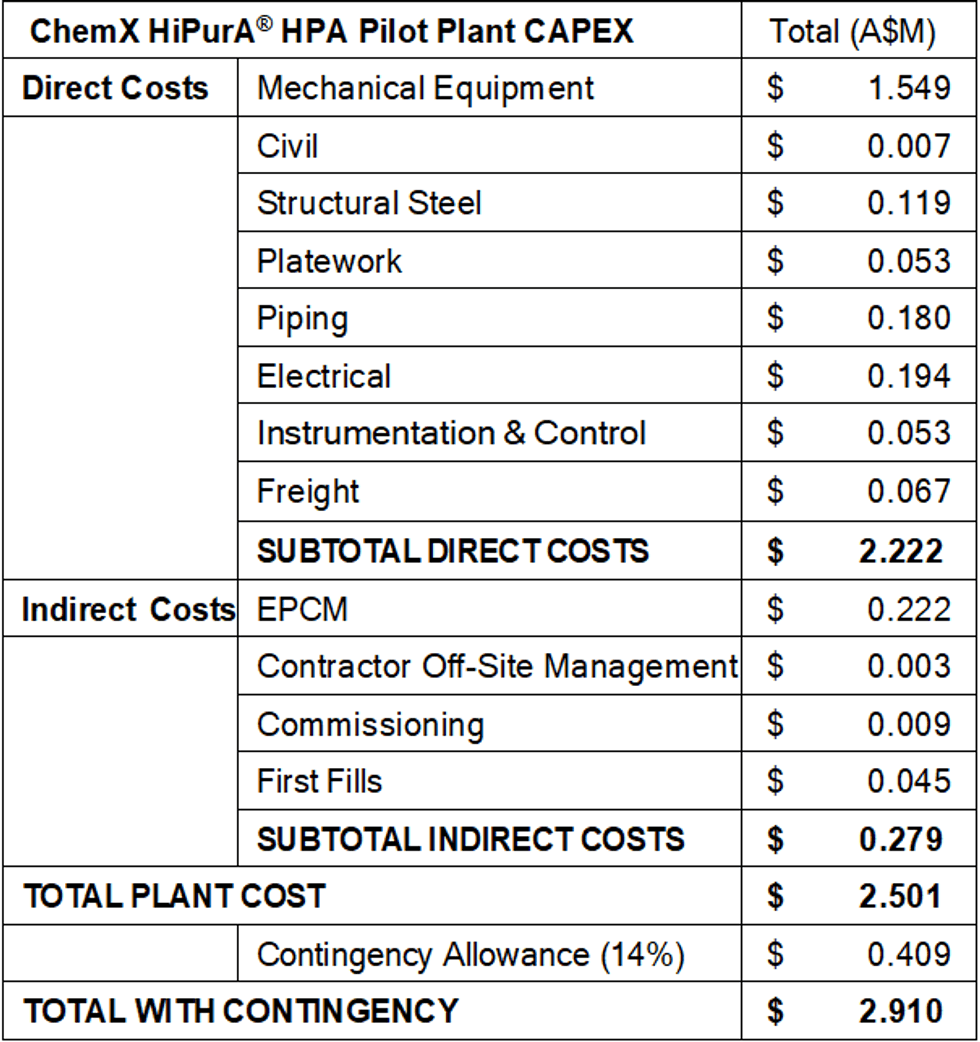

The PFS, conducted by engineering firm Primero Group, indicates the 50 tonne per annum (tpa) pilot plant requires capital expenditure of A$2.5 million with a contingency of A$0.41 million. Using data obtained from the Company’s successful HPA micro-plant commissioning phase and subsequent operation, the PFS incorporated several work streams and equipment modifications which have led to the design of an appropriately sized pilot plant.

The aims of the HiPurA® HPA pilot plant are to:

- Optimise operating conditions to reduce the scale-up risks associated with a commercial plant

- Produce the larger quantities of HPA needed for the final stages of qualification

- Continue with development of additional materials that the HiPurA® technology can produce

Table 1: Cost breakdown - HiPurA® HPA Pilot Plant CAPEX

High Purity Alumina (HPA) is a high value critical material used in lithium-ion batteries to manufacture ceramic separators, which provide increased thermal insulation for improved safety and charging. HPA is also an irreplaceable ingredient in the production of synthetic sapphire, which is used in LEDs, semiconductors, and optical lenses.

ChemX completed the commissioning of the individual stages of its HPA micro-plant prior to the conclusion of the 2nd Quarter 2022. The micro-plant shall continue to be utilised, alongside the development of the pilot plant.

The key objectives of the micro-plant are:

- Optimisation of process and controls under continuous operation

- Achieving a 99.99% (4N) Purity HPA on a consistent basis

- Production of HPA samples to be used for customer qualification testing

- Research and development of additional products for assessment including achieving a targeted 99.999% (5N) Purity and aluminium sulphate / aluminium nitrate for lithium battery cathodes.

Following successful production of HPA through the continuous operation of the HiPurA® micro-plant the Company has submitted samples to an accredited laboratory for assaying. Chemical analysis will provide ChemX with the ability to specifically calibrate the final purification step to produce 4N HPA, capable of being used as a coating on the separator between the cathode and anode of lithium-ion batteries.

Click here for the full ASX Release

This article includes content from ChemX Materials, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

CMX:AU

The Conversation (0)

01 July 2024

ChemX Materials

Critical materials company developing innovative, processing technology to produce high purity alumina for advanced technology and clean energy applications.

Critical materials company developing innovative, processing technology to produce high purity alumina for advanced technology and clean energy applications. Keep Reading...

28 November 2024

Agreement with Vytas Ltd for High Purity Assay Services

ChemX Materials (CMX:AU) has announced Agreement with Vytas Ltd for High Purity Assay ServicesDownload the PDF here. Keep Reading...

Latest News

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00