THIS NEWS RELEASE IS NOT FOR DISTRIBUTION TO U.S. NEWSWIRE SERVICES FOR DISSEMINATION IN THE UNITED STATES

South Star Battery Metals Corp. ("South Star" or the "Company") (TSXV:STS)(OTCQB:STSBF), is pleased to announce that it has awarded contracts for the National Instrument 43-101 ("NI43-101") Preliminary Economic Assessment ("PEA" or the "Study") for the BamaStar Graphite Project ("BamaStar"). The interdisciplinary team of consultants, engineers and scientists is co-led by Dorfner ANZAPLAN GmbH and Lycopodium Limited. The PEA is anticipated to be completed and published in July 2024. With the recent mineral lease and surface rights extensions, South Star has successfully completed all the other requirements for BamaStar's option agreement, and preparing the PEA is the final milestone that will give the Company the right to acquire an undivided 75% legal and beneficial interest in and to the minerals, mining rights and the underlying agreements for the mine

The PEA will incorporate the Company's 2023 drill-program results, providing an update to the maiden Mineral Resource Estimate for the BamaStar project. The Study's techno-economic analysis will present a scenario with concentrates from both BamaStar and Santa Cruz providing feedstocks for the secondary processed, specialty-graphite products. The Study will outline the strategic production/commercial plan for South Star's planned downstream transformation plant for the manufacturing of battery-graphite and other specialty-graphite commercial products, in the southeastern USA.

Additionally, senior representatives of the Company have engaged and met with numerous senior economic-development representatives for states in the region, including Alabama and Louisiana. The team has commenced a site-selection process to determine the most advantageous location for siting South Star's planned downstream transformation plant to produce coated spherical purified graphite ("CSPG") for lithium-ion ("Li-ion") battery applications, in addition to conductivity-enhancement products suited for numerous battery chemistries, and other unique and innovative products.

Richard Pearce, CEO of South Star, commented, "We are pleased to kickoff the PEA for BamaStar and to advance the project together with our partners. The PEA is expected to take approximately three to four months to complete, and we believe it will present a robust scenario with two scalable mines producing high-quality concentrates and a value-add plant in the middle of one of the most critical EV, defense, and energy storage corridors in the U.S. At a time of increasing geopolitical risks and supply-chain concerns regarding critical metals and the energy transition, it's great to be one of the first movers advancing a phased, vertically integrated graphite supply chain with near-term production and high-quality assets in Tier 1 jurisdictions in the Americas."

In addition, 10 kg of Santa Cruz material is being tested as part of ongoing characterization and optimization of the Santa Cruz graphite concentrates for battery applications for the Company's US downstream transformational technologies technical program. Currently, Santa Cruz graphite concentrate is being analyzed, purified, transformed and upgraded to produce a variety of different products, including CSPG.

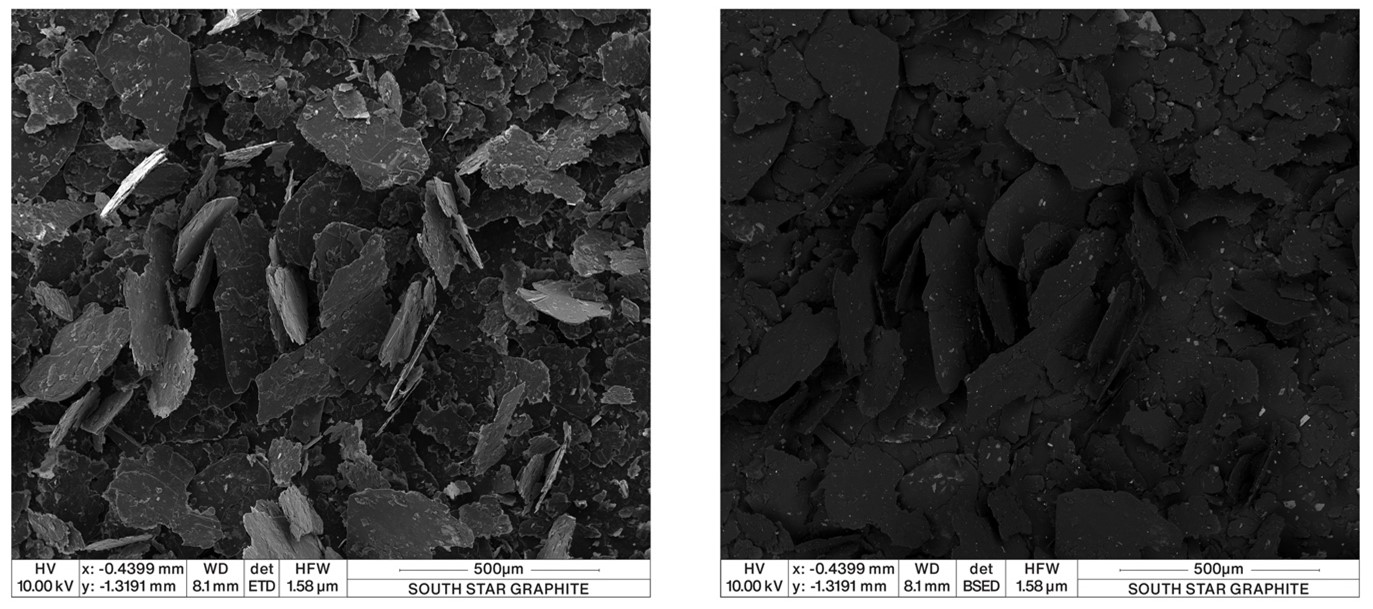

As part of that ongoing characterization, the as-received Santa Cruz graphite concentrate was recently imaged using scanning electron microscop ("SEM"), as shown in the Figure 1 below.

Figure 1: The SEM image on the above left is of South Star's >96% Cg graphite concentrate from the Santa Cruz Graphite Mine in Brazil. The SEM image on the above right is of the EXACT same material as in the image on the left, imaged concurrently, but utilizing a SEM backscattered electron detector. Backscattered electron imaging is used to differentiate between materials of different compositions. Phases heavier than carbon will look bright (meaning, impurities will luminesce), and pure carbon will look matte black, as seen here. The even coloration demonstrates the >96% C purity of the Santa Cruz graphite concentrate.

ABOUT DORFNER ANZAPLAN GmbH

Dorfner is a leading European specialty minerals producer delivering high-quality mineral products to different industries. ANZAPLAN was founded in 1985 to become the most independent venture within the Dorfner group of companies while concentrating the group's analytical and engineering know-how to serve external customers. Extensive know-how in specialty minerals processing, including liberation of fine-grained minerals, separation, flotation, and mechanical, chemical, and thermal modification derived from more than a century of day-to-day processing experience at Dorfner, has been successfully applied in the processing of various graphite raw materials. Furthermore, ANZAPLAN has detailed expertise in advanced chemical and thermal purification, upgrading graphite concentrates to >99.9% purity levels. Today ANZAPLAN is a specialist with a strong focus on specialty minerals and metals businesses (e.g. graphite, lithium minerals, rare-earth elements, high purity quartz), providing a one-stop-shop solution across all phases of the economic evaluation and process development -- with technological expertise from its laboratories, test-center and pilot-plant processing facilities including basic and advanced engineering services.

Purification processes including mechanical, chemical, and thermal-refinement technologies are key elements in ANZAPLAN's and Dorfner's daily business to efficiently remove impurities by targeting high-value products. ANZAPLAN's experience in the processing of graphite includes extensive test work carried out for several different projects including flake and hydrothermal vein graphite deposits as well as processing of synthetic graphite.

LYCOPODIUM LIMITED

Lycopodium is a leader in its field, working with clients globally to provide integrated engineering, construction and asset management solutions. The company has the expertise to deliver complex, multidisciplinary projects, through to the provision of feasibility studies and advisory services.

Operating across the resources, infrastructure and industrial-processes sectors, Lycopodium offers a diverse team of industry experts to deliver bespoke and innovative solutions across all commodity types. With the capability to deliver projects around the world, the company has offices in Australia, South Africa, Canada, Ghana and the Philippines.

About South Star Battery Metals Corp

South Star Battery Metals Corp. is a Canadian battery metals project developer focused on the selective acquisition and development of near-term production projects in the Americas. South Star's Santa Cruz Graphite Project, located in Southern Bahia, Brazil is the first of a series of industrial and battery metals projects that will be put into production. Brazil is the second-largest graphite-producing region in the world with more than 80 years of continuous mining. Santa Cruz has at-surface mineralization in friable materials, and successful large-scale pilot-plant testing (> 30t) has been completed. The results of the testing show that approximately 65% of graphite concentrate is +80 mesh with good recoveries and 95%-99% graphitic carbon (Cg). With excellent infrastructure and logistics, South Star is fully funded for Phase 1, and the construction and commissioning are underway. Santa Cruz will be the first new graphite production in the Americas since 1996, with Phase 1 commercial production projected in Q2 2024. Phase 2 production (25,000 tpa) is partially funded and planned for 2026, while Phase 3 (50,000 tpa) is scheduled for 2028.

South Star's second project in the development pipeline is strategically located in Alabama in the center of a developing electric vehicle, aerospace, and defense hub in the southeastern United States. The BamaStar Project includes a historic mine active during the First and Second World Wars. A NI43-101 technical report with the maiden resource estimate has been filed on SEDAR. Trenching, Phase 1 drilling, sampling, analysis, and preliminary metallurgical testing have been completed. The testing indicates a traditional crush/grind/flotation concentration circuit that achieved grades of approximately 94-97% Cg with approximately 86% recoveries. South Star is executing on its plan to create a multi-asset, diversified battery metals company with near-term operations in strategic jurisdictions. South Star trades on the TSX Venture Exchange under the symbol STS, and on the OTCQB under the symbol STSBF.

South Star is committed to a corporate culture, project execution plan and safe operations that embrace the highest standards of ESG principles, based on transparency, stakeholder engagement, ongoing education, and stewardship. To learn more, please visit the Company website at http://www.southstarbatterymetals.com.

This news release has been reviewed and approved by Richard Pearce, P.E., a "Qualified Person" under National Instrument 43-101 and President and CEO of South Star Battery Metals Corp.

On behalf of the Board,

MR. RICHARD PEARCE

Chief Executive Officer

For additional information, please contact:

South Star Investor Relations

Email: invest@southstarbatterymetals.com

Phone: +1 (604) 706-0212

Website: www.southstarbatterymetals.com

Twitter: https://twitter.com/southstarbm

Facebook: https://www.facebook.com/southstarbatterymetals

LinkedIn: https://www.linkedin.com/company/southstarbatterymetals/

YouTube: South Star Battery Metals - YouTube

Forward-Looking Information

This press release contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements". Forward-looking statements in this press release include, but are not limited to, statements relating to the successful closing of the Private Placement and anticipated timing thereof and the intended use of proceeds and statements regarding moving Santa Cruz into production and scaling operations as well as advancing the Alabama project and the Company's plans and expectations.

Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: risks related to failure to obtain adequate financing on a timely basis and on acceptable terms; risks related to the outcome of legal proceedings; political and regulatory risks associated with mining and exploration; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company's expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Investors are cautioned against attributing undue certainty to forward-looking statements. These forward-looking statements are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances. Actual events or results could differ materially from the Company's expectations or projections.

This news release does not constitute an offer to sell or a solicitation of an offer to buy any of the securities in the United States. The securities have not been and will not be registered under the United States Securities Act of 1933, as amended (the "U.S. Securities Act") or any state securities laws and may not be offered or sold within the United States or to U.S. Persons unless registered under the U.S. Securities Act and applicable state securities laws or an exemption from such registration is available.

NEITHER THE TSX VENTURE EXCHANGE, NOR ITS REGULATION SERVICE PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THE CONTENT OF THIS NEWS RELEASE.

SOURCE: South Star Battery Metals Corp.

View the original press release on accesswire.com