Metamaterial Inc. (the "Company" or "META") (CSE:MMAT) a developer of high-performance functional materials and nanocomposites, today announced that it is presenting an expanded range of products and technologies at Photonics West, March 6-11, 2021, and new products will be added to the META online store. For smart eyewear, metaFUSION™ combines embedded ARVR functionality with precision cast prescription lenses. For laboratory applications, two new series of conventional and anomalous notch filters are being added to the metaOPTIX™ holographic filter range. The metaAIR® laser glare protection family is expanding to include applications for law enforcement and sensors. For application development, NanoWeb® transparent conductive film will be available with tailored mesh designs of optimized transparency, haze, and conductivity for each application

"To enable augmented reality as a wearable technology platform, the industry is still searching for a solution that is both functional and fashionable, while also meeting the needs of the majority of users who require corrective lenses," said Jonathan Waldern, Chief Technology Officer of META. "With the assets and IP we acquired from Interglass, META is developing a vertical solution that will meet this challenge for head mounted displays."

"META's platform technology is aimed at delivering breakthrough performance across a range of applications and industries," said George Palikaras, President and CEO. "We are excited to showcase our capabilities at Photonics West, and to make our solutions more accessible, as we engage with a growing list of customers and partners."

metaFUSION™ Vertical Solution for Smart Eyewear

To be successful, META believes that smart eyewear for augmented reality (AR) applications must deliver high image quality across a wide field of view in a form factor that is both comfortable for everyday use and unobtrusive. To accomplish this, the AR optical elements must be embedded within prescription capable lenses. META is developing metaFUSION to support this capability with precision cast corrective lenses, using a process which requires significantly less material, energy, and water than conventional production.

metaOPTIX™ Expanded Range of Optical Filters

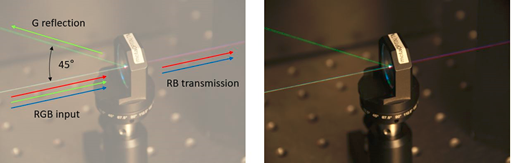

metaOPTIX SLANT reflects light at unusual angles

Optical filters are used to block and manipulate laser light sources in applications such as fluorescence or Raman spectroscopy. In November 2020, META introduced 12 models of large area holographic film notch filters. Now, META is introducing metaOPTIX STRATA, notch filters in an industry standard, 1-inch diameter glass form factor, and metaOPTIX SLANT, with the unique capability to anomalously reflect a specific wavelength of light at unusual angles. By eliminating the need to tilt the filter in the optical path, this new line will give optical engineers a new option to compact and miniaturize their designs.

metaAIR® Laser Glare Protection Solutions for Law Enforcement and Sensors

Green laser pointers are widely available, creating a hazard for law enforcement personnel, including helicopter pilots and crew, motorcycle officers, and personnel engaged in crowd control. Officers struck by laser light may be distracted or temporarily flash-blinded, hampering their ability to operate. metaAIR laser glare protection filters may be applied to eyewear and goggles, helmet visors, and riot shields, blocking green laser light, while maintaining high transparency for other wavelengths. This is crucial for personnel to maintain operational effectiveness, especially in low light conditions. META is also developing solutions for sensors, such as security cameras, lidars, and night vision systems, which are susceptible to dazzling and even permanent damage from lasers.

NanoWeb® Transparent Conductive Film

NanoWeb®

Transparent conductors are integral components in a wide range of electronic devices including touchscreens, OLEDs, and photovoltaics. They can also be used on optical components of sensors and display systems as EMI shielding and transparent heater elements. META has developed NanoWeb®, a unique, and more sustainable product in the domain of transparent conductors. Unlike competing transparent conductor products based on Indium Tin Oxide (ITO), NanoWeb® is flexible, and does not require scarce raw materials.

NanoWeb® consists of invisible nanostructured metal wire mesh, which can be fabricated for large area products and flexible devices in roll-to-roll fashion using Rolling Mask Lithography, RMLTM. NanoWeb® has superior conductivity (1-10 W/sq) and transparency (95%-99%) compared to alternative technologies and demonstrates excellent performance for transparent heating and EMI shielding. META provides custom NanoWeb® solutions with tailored mesh designs of optimized transparency, haze, and conductivity for each application.

About Metamaterial Inc.

META is changing the way we use, interact with, and benefit from light and other forms of energy. META designs and manufactures advanced materials and performance functional films which are engineered at the nanoscale to control light and other forms of energy. META is an award winning Global Cleantech 100 company with products that support sustainability by doing more with less; they encompass lightweight, sustainable raw materials and processes which consume less energy and offer more performance. META has a growing patent portfolio and is currently developing new materials with diverse applications in concert with companies in the automotive, aerospace, energy, consumer electronics and medical industries. META is headquartered in Halifax, Nova Scotia and has R&D and Sales offices in London, UK and Silicon Valley. For additional information on META, please visit www.metamaterial.com.

Media inquiries:

media@metamaterial.com

Investor inquiries:

Mark Komonoski

Investor Relations

phone: 1-877-255-8483

mark@metamaterial.com

Forward Looking Information

This release includes forward-looking information within the meaning of Canadian securities laws regarding the Company and its business, which may include, but are not limited to, statements with respect to the business strategies and operational activities of the Company. Often but not always, forward-looking information can be identified by the use of words such as "expect", "intends", "anticipated", "believes" or variations (including negative variations) of such words and phrases, or state that certain actions, events or results "may", "could", "would" or "will" be taken, occur or be achieved. Such statements are based on the current expectations and views of future events of the management of the Company and are based on assumptions and subject to risks and uncertainties. Although the management of the Company believes that the assumptions underlying these statements are reasonable, they may prove to be incorrect. The forward-looking events and circumstances discussed in this release may not occur and could differ materially as a result of known and unknown risk factors and uncertainties affecting the companies, including risks regarding the ability, performance and usefulness of metaFUSION, metaAIR NanoWeb, metaOPTIX, metaOPTIX STRATA, and metaOPTIX SLANT, and, the ability of the Company to commercialize its prototypes, and the ability of the Company to expand into other uses. Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking statements, there may be other factors that cause actions, events or results to differ from those anticipated, estimated or intended. Accordingly, readers should not place undue reliance on any forward-looking statements or information. No forward-looking statement can be guaranteed. Except as required by applicable securities laws, forward-looking statements speak only as of the date on which they are made and the Company does not undertake any obligation to publicly update or revise any forward looking statement, whether as a result of new information, future events, or otherwise.

The CSE has neither approved nor disapproved the contents of this news release.

SOURCE: Metamaterial Inc.

View source version on accesswire.com:

https://www.accesswire.com/633955/META-Presents-Expanded-Range-of-Products-and-Technologies-at-Photonics-West