September 28, 2023

Assay confirms 4N (99.99%) HPA across an impressive 66 elements

ChemX Materials Ltd (ASX: CMX) (ChemX or Company), an Australian based high purity critical materials developer, is delighted to announce recent results from its High Purity Alumina (HPA) Micro Plant operations, located in Perth, Western Australia.

- Micro Plant achieves 4N (99.99%) purity High Purity Alumina (HPA) across 66 elements critical for the global battery and energy transition market.

- ChemX products on the pathway to deliver high purity materials to the global battery industry, the synthetic sapphire markets, LEDs, semi-conductor and optical lenses for testing and qualification, subject to suitable quantities of HPA being produced.

- ChemX’s 100%-owned HiPurA® technology delivers key milestone within 12 months since commissioning HPA facility.

- The HiPurA® process is modular, scalable and independent of direct mine production, which enables ChemX to locate key future production facilities close to customers in a just-in-time customised approach.

ChemX’s 100%-owned HiPurA® chemical feedstock process has delivered an outstanding 4N (99.99%) HPA result across an impressive 66 element spectrum. The Company is now working to ensure repeatability of this result through continued plant optimisation as it seeks to scale up the process to pilot plant scale.

Importantly, achieving a 4N product involves a sample quality with impurities of less than 100 parts per million and this quality is what is required for testing and qualification to commence for the global battery separator market.

In late CY2022, ChemX commissioned its Integrated HPA Facility with the goal of advancing the scale up of the HiPurA® HPA flowsheet from laboratory scale to continuous operation.

Chief Executive Officer, Peter Lee commented:

“The Company is extremely proud to have achieved an outstanding result from our Micro Plant, with detailed logged data from feedstock delivery through each stage of the process being achieved.

“I’d like to acknowledge our best-in-class team who have succeeded in calibration of the novel HiPurA® process with highly effective removal of deleterious elements.

“This is a proud day for CMX shareholders and the team,” Mr Lee said.

“Today’s break through validates the disruptive nature of the HiPurA® process and ChemX views that the ability to achieve bespoke high purity (4N) outcomes in a locally-based, scalable, modular format may be a game-changer for gigafactory feedstock management”.

“Importantly, data obtained during the optimisation of the Micro Plant will be included in the current Pilot Plant (design) which will produce sufficient sample volumes for global customer qualification,” Mr Lee said.

Next steps:

The World Intellectual Property Organisation (WIPO) issued an International Preliminary Report on Patentability for the HiPurA® process, finding that claims 1-26 complied with requirements for novelty, inventive step and industrial applicability. The International Patent Application process is ongoing.

The Company is moving forward to make further strategic investments in high purity analytical equipment and necessary resources to speed process iteration and optimisation. Process control data logged during production will work to ensure robust repeatability.

The Company has achieved solid results which satisfy known commercial specifications for HPA, but has been driving the HiPurA® process beyond this distinction to instead achieve an outstanding result across an impressive 66 element spectrum, validating the exceptional efficacy of the HiPurA® process.

Notes:

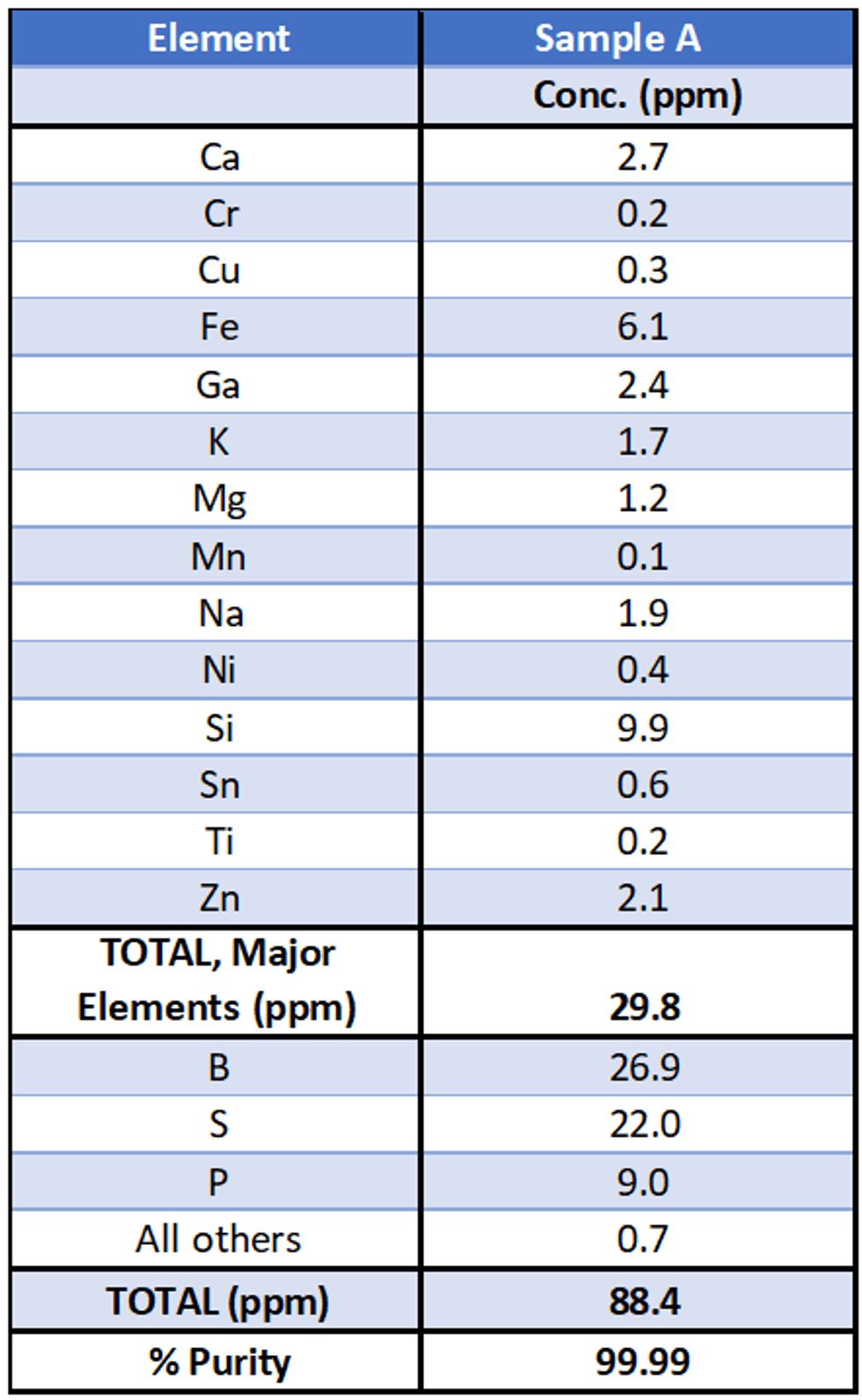

1) ‘Major Elements’ listed represent the 14 elements most commonly reported within commercial HPA specifications.

2) Analysis conducted by LabWest Minerals Analysis Pty Ltd. (NATA accredited Laboratory)

2) Analysis Method – Microwave Digest, HF/Multiacid, 66 Elements including REE’s by ICP-MS/OES.

3) Complete analysis provided in Appendix A

About the HiPurA® 100% owned process

CMX’s HiPurA® process is a disruptive flowsheet which converts aluminous chemical feedstocks through selective refining to HPA. Ultimately, CMX aims to achieve the delivery of 4N high grade and potentially 5N (99.999%) HPA products for the electric vehicle battery separator and synthetic sapphire markets, LEDs, semi-conductor and optical lenses.

The HiPurA® process is modular, scalable and independent of direct mine production, which enables ChemX to locate key future production facilities close to customers in a just-in-time customised approach.

Click here for the full ASX Release

This article includes content from ChemX Materials, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

CMX:AU

The Conversation (0)

01 July 2024

ChemX Materials

Critical materials company developing innovative, processing technology to produce high purity alumina for advanced technology and clean energy applications.

Critical materials company developing innovative, processing technology to produce high purity alumina for advanced technology and clean energy applications. Keep Reading...

28 November 2024

Agreement with Vytas Ltd for High Purity Assay Services

ChemX Materials (CMX:AU) has announced Agreement with Vytas Ltd for High Purity Assay ServicesDownload the PDF here. Keep Reading...

Latest News

Interactive Chart

Latest Press Releases

Equity Metals Exhibiting at the 2026 PDAC

06 February

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00