Lac Knife graphite shows 26% higher cathode density in battery test, opening premium market opportunities beyond anodes, and zero-waste potential.

Focus Graphite Inc. (TSXV: FMS,OTC:FCSMF) (OTCQB: FCSMF) (FSE: FKC0) ("Focus" or the "Company"), a leading Canadian graphite developer advancing high-grade projects in Quebec, is pleased to announce highly encouraging early results from independent battery cell testing conducted by Charge CCCV LLC ("C4V"), a New York-based leader in lithium-ion battery technology and gigafactory design.

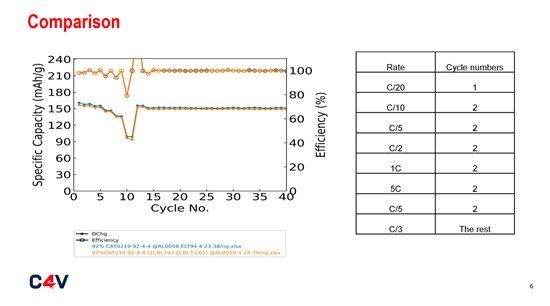

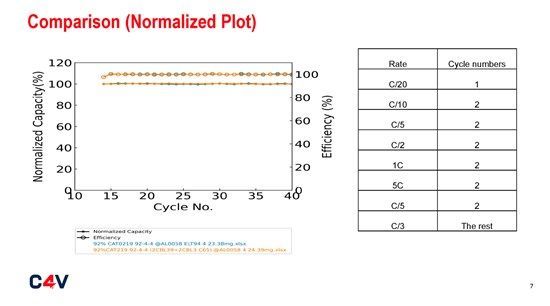

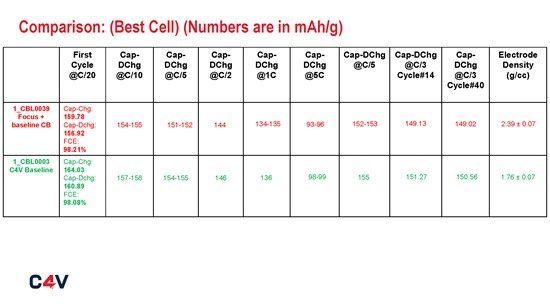

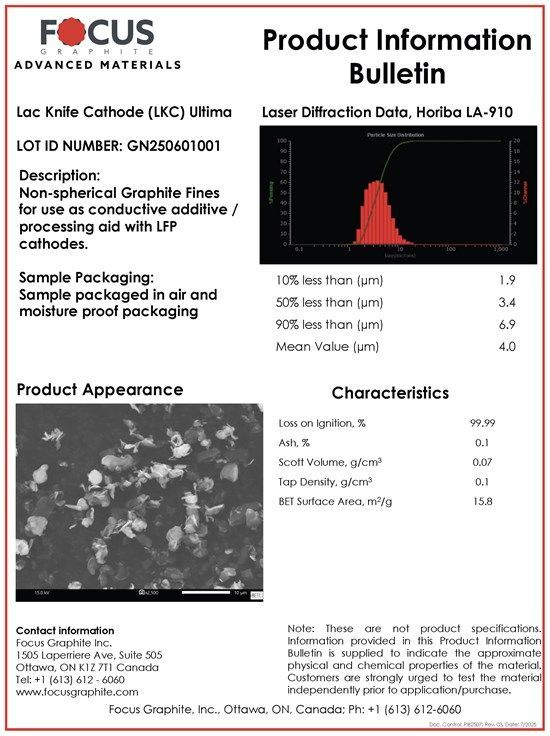

Initial results demonstrate that spheroidization rejects from the Lac Knife deposit - typically considered waste - produced a twenty-six percent (26%) increase in cathode electrode density in single-side coated electrodes (2.39 g/cc vs. 1.76 g/cc baseline). A total of four percent (4%) conductive additive was used in the lithium iron phosphate ("LFP") cathode, made up of two percent (2%) carbon black and two percent (2%) Lac Knife Cathode (LKC) Ultima (50:50 ratio). The tests also showed equivalent conductivity and comparable cycling stability up to forty (40) cycles. These findings suggest Lac Knife graphite by-products may represent a high-value conductive additive and significant energy-storage advantages with potential to replace or complement carbon black, the industry standard, while enabling a zero-waste processing model.

Higher cathode density allows more active material to be packed into each cell, effectively increasing energy storage without enlarging the battery size. This improvement allows battery manufacturers to achieve higher volumetric energy density, better efficiency, and lower cost per kilowatt-hour, all while maintaining the inherent safety and cycle life of LFP cells like C4V's BMLMP (P Series cells) which currently increase voltage and energy density by fifteen percent (15%) compared to typical LFP cells. With this innovation, Focus is enabling the next generation of high-performance, cost-effective lithium-ion batteries - an advantage that is particularly meaningful for Battery Energy Storage Systems (BESS) supporting renewable energy & EV systems. The ability to achieve greater density without sacrificing conductivity or cycling stability underscores the potential value of Lac Knife graphite as a next-generation conductive additive.

This opportunity is further reinforced by the rapid growth in the market for lithium-ion battery (LIB) cathode conductive auxiliary agents. According to a January 2025 report by Markets and Markets, the global market is expected to expand from approximately US$1.80 billion in 2024 to US$4.32 billion by 2029, representing a compound annual growth rate (CAGR) of about 19.1%1. With such robust growth forecasts, early evidence that Lac Knife graphite can compete with and potentially outperform conventional carbon black highlights the strategic opportunity for Focus Graphite to participate in a high-value, high-growth specialty market.

If validated through larger-scale testing, this breakthrough could enable Focus to fully utilize its concentrate, create high-value by-products, and diversify into cathode markets all while offering ESG advantages through Quebec's renewable hydro energy and a potential clean-energy carbon footprint. The Company plans to advance testing to single pouch cells (150mAh) & multilayer pouch cells (3Ah), explore different blend ratios (e.g. 60/40 or 70/30), and continue joint validation with C4V to assess scalability.

"These early results validate the potential for Lac Knife graphite to expand beyond anode applications," said Baasit Ali Shaik Sulaiman, VP Supply Chain of C4V. "Often single digit improvements in battery applications are notable. We look forward to advancing this collaboration through larger format batteries as part of our Digital DNA® program and the potential of this product for the North American supply chain."

"We continue to showcase the versatility of our Lac Knife deposit," said Dean Hanisch, CEO of Focus Graphite. "A twenty-six percent improvement in cathode density is an encouraging early result in an industry where even small gains matter. Enabled by Lac Knife's unique flake and our use of a thermal fluidized bed oven, these findings suggest that by-products may be transformed into high-value cathode materials with zero-waste potential. While further testing and validation are required, this work indicates possible applications in Battery Energy Storage Systems, one of the fastest-growing segments of the market. This aligns with our strategy to maximize the value of Lac Knife's graphite flakes and advance opportunities to supply premium materials to downstream customers."

Figure 1: Cycle Performance Comparison: LKC Ultima Blend vs. C4V Baseline Carbon Black

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/266408_fe817751b4ae59a7_001full.jpg

Figure 2: Normalized Cycling Comparison of LKC Ultima Blend vs. C4V Baseline Carbon Black

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/266408_fe817751b4ae59a7_002full.jpg

Figure 3: Summary of Cathode Performance Metrics, LKC Ultima Blend vs. C4V Baseline Carbon Black

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/266408_fe817751b4ae59a7_003full.jpg

Figure 4: Product Information Bulletin for Lac Knife Cathode (LKC) Ultima

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/266408_fe817751b4ae59a7_004full.jpg

About Charge CCCV (C4V)

C4V™ is a lithium-ion battery technology company possessing critical insights related to the optimum performance of lithium-ion batteries and Gigafactory's. C4V's discoveries have been fruitful in vastly extending battery life, safety and charge performance, however more important is the Gigafactory offering that allows emerging countries to establish their own robust manufacturing ecosystem. C4V works with industry-leading raw material suppliers and equipment supply chain to bring to market fully optimized batteries possessing key economic advantages providing the ultimate "best in class" performance for various applications and end- to-end solutions to produce them on a Gigawatt hour scale. With its unique and innovative business model C4V is rapidly gearing towards 100+GWh of cell production capacity globally by 2032 and its Digital DNA Supply Chain solution ensures materials meet the highest industry standards for performance and reliability.

For more information on C4V please visit http://www.chargecccv.com.

About Focus Graphite Advanced Materials Inc.

Focus Graphite Advanced Materials is redefining the future of critical minerals with two 100% owned world-class graphite projects and cutting-edge battery technology. Our flagship Lac Knife project stands as one of the most advanced high-purity graphite deposits in North America, with a fully completed feasibility study. Lac Knife is set to become a key supplier for the battery, defense, and advanced materials industries.

Our Lac Tetepisca project further strengthens our portfolio, with the potential to be one of the largest and highest-purity and grade graphite deposits in North America. At Focus, we go beyond mining - we are pioneering environmentally sustainable processing solutions and innovative battery technologies, including our patent-pending silicon-enhanced spheroidized graphite, designed to enhance battery performance and efficiency.

Our commitment to innovation ensures a chemical-free, eco-friendly supply chain from mine to market. Collaboration is at the core of our vision. We actively partner with industry leaders, research institutions, and government agencies to accelerate the commercialization of next-generation graphite materials. As a North American company, we are dedicated to securing a resilient, locally sourced supply of critical minerals - reducing dependence on foreign-controlled markets and driving the transition to a sustainable future.

For more information on Focus Graphite Inc. please visit http://www.focusgraphite.com

Investors Contact:

Dean Hanisch

CEO, Focus Graphite Inc.

dhanisch@focusgraphite.com

+1 (613) 612-6060

Jason Latkowcer

VP Corporate Development

jlatkowcer@focusgraphite.com

Cautionary Note Regarding Forward-Looking Statements

Certain statements contained in this press release constitute forward-looking information. These statements relate to future events or future performance. The use of any of the words "could," "intend," "expect," "believe," "will," "projected," "estimated," and similar expressions, as well as statements relating to matters that are not historical facts, are intended to identify forward-looking information and are based on the Company's current beliefs or assumptions as to the outcome and timing of such future events.

In particular, this press release contains forward-looking information relating to, among other things, the potential applications of Lac Knife graphite by-products as conductive additives in lithium iron phosphate (LFP) cathodes, the significance of the twenty-six percent (26%) improvement in electrode density observed in early testing, and the anticipated benefits of higher cathode density for energy storage systems. It also includes statements regarding the Company's ability to fully utilize its concentrate, create high-value by-products, diversify into cathode markets, and deliver environmental, social, and governance (ESG) advantages through Québec's hydro-powered, low-carbon energy infrastructure. Forward-looking information further includes the Company's plans to advance testing beyond coin cells into pouch cells, to explore alternative blend ratios, and to continue collaboration with Charge CCCV LLC ("C4V") to validate scalability.

Forward-looking statements are subject to known and unknown risks, uncertainties, and other factors that may cause actual results, performance, or achievements to differ materially from those expressed or implied by such statements. These risks and uncertainties include, but are not limited to, risks related to market conditions, regulatory approvals, changes in economic conditions, the ability to raise sufficient funds on acceptable terms or at all, operational risks associated with mineral exploration and development, and other risks detailed from time to time in the Company's public disclosure documents available under its profile on SEDAR+.

The forward-looking information contained in this release is made as of the date hereof, and the Company is not obligated to update or revise any forward-looking information, whether as a result of new information, future events, or otherwise, except as required by applicable securities laws. Because of the risks, uncertainties, and assumptions contained herein, investors should not place undue reliance on forward-looking information.

Neither TSX Venture Exchange nor its Regulation Services accepts responsibility for the adequacy or accuracy of this release.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/266408