December 20, 2023

The Board of Ionic Rare Earths Limited (“IonicRE” or “the Company”) (ASX: IXR) is pleased to advise progress at Ionic Technologies International Ltd (“Ionic Technologies”), a 100% owned subsidiary based in Belfast, UK.

- Ionic Technologies Magnet Recycling Demonstration Plant in Belfast, UK, is progressing to schedule and readies plant to operate 24/7 from early January 2024;

- Process control system commissioning nearing conclusion, expected to be finished this week;

- Pre-production has commenced, preparing digestion feed streams plus several intermediate streams in advance of UK government sponsored collaborative project with Ford and Less Common Metals; and

- Several further supply chain collaborations with rare earth metal, alloy and magnet manufacturers plus Original Equipment Manufacturers (OEMs) underway to expand global offering from Ionic Technologies.

Ionic Technologies is a global first mover in the recycling of Neodymium-Iron-Boron (NdFeB) permanent magnets to high purity separated magnet rare earth oxides (REOs), enabling the creation of sustainable, traceable and sovereign rare earth supply chains.

Following our announcement on 12 September 2023, Ionic Technologies successfully secured funding for two CLIMATES grants from the UK Government’s Innovate UK totalling £2 million (A$3.90 million). These successful grant funding submissions centred on two CLIMATES projects:

During 2023, Ionic Technologies constructed a magnet recycling Demonstration Plant and produced initial quantities of high purity (> 99.5%) neodymium (Nd) and dysprosium (Dy) rare earth oxides (REOs) (ASX: 19 June 2023). After initial process commissioning and production runs through Q3 2023, Ionic Technologies installed additional processing equipment and is in the final stages of upgrading the installed control system which is now undergoing final commissioning. Ionic Technologies is on track to go to 24/7 operations from early January 2024, with commercial production runs to support the LCM and Ford collaboration commencing immediately thereafter.

Additional supply chain engagement discussions have progressed based upon reverse enquiry post- production of high purity REOs in June 2023, and the Company is evaluating several additional opportunities.

Pre-production has commenced ahead of 24/7 operation, with over 300 kg of magnets being processed and over 700kg of magnet slurry being prepared for processing in the Demonstration Plant.

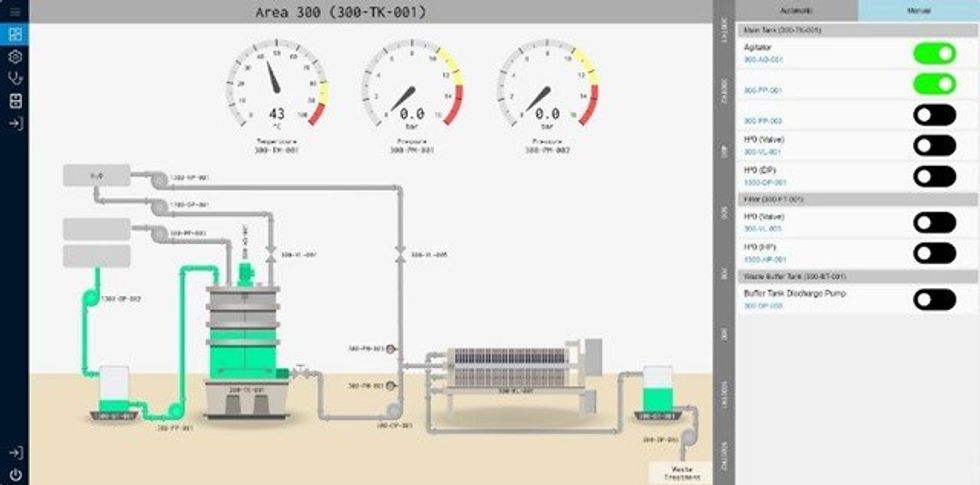

In order to maximise demonstrable efficiency through the pre-treatment and separation processes in the Demonstration Plant, Ionic Technologies have invested in a first-of-kind control system, specifically designed for the complexities of the patented process for magnet recycling and REO recovery.

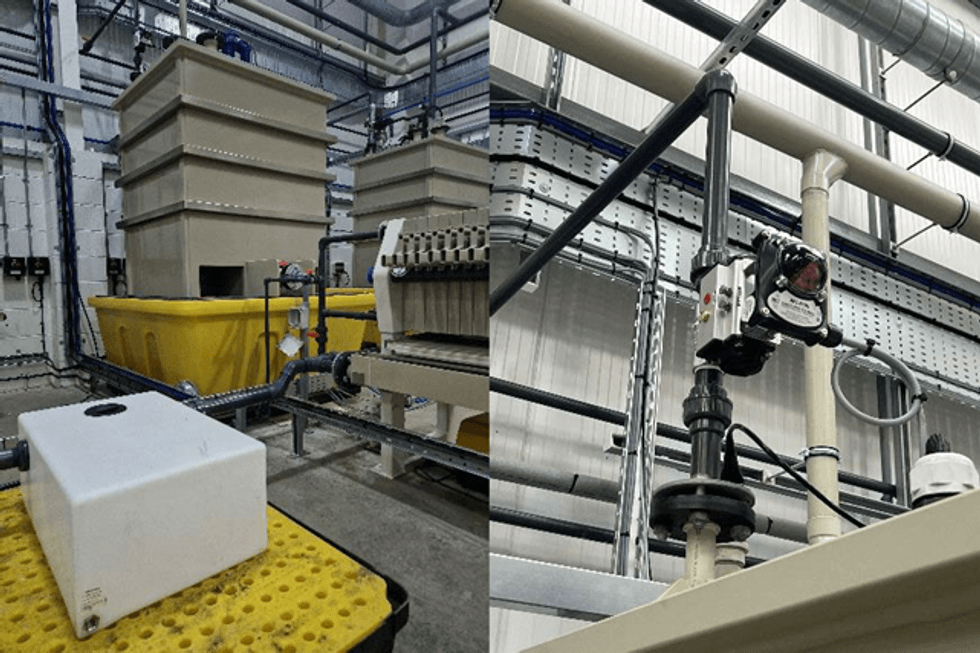

Custom filter presses have been manufactured, installed and commissioned. This additional process capability allows for safe solid/liquid separation across multiple pre-processing stages, across multiple processes to recover separate magnet rare earths.

The presses were designed to enable separation of solids, under the unique conditions created within Ionic Technologies’ patented processes. Ionic Technologies partnered with Andritz AG to develop Engineered-to-Order SE470CD filter presses (see Figure 3), which have now been installed and integrated into the process.

To facilitate the significant number of new production projects and demand for recycled magnet REOs coming from rare earth permanent magnet supply chain partners, including Less Common Metals and Ford, Ionic Technologies have expanded the operations team in readiness for an extensive campaign through 2024 and beyond.

Technology Overview

Since its founding in 2015, as a spinout from Queens University Belfast (QUB), Ionic Technologies has developed processes for the separation and recovery of REEs from mining ore concentrates and waste permanent magnets.

The technology developed is a step up in efficient, non-hazardous, and economically viable processing with minimal environmental footprint.

The Company’s proprietary technology provides a universal method for the recovery of high purity grade rare earth elements from lower quality and variable grade magnets, to be used in the manufacture of modern high-performance and high specification permanent magnets required to support substantial growth in both electric vehicle (EV) and wind turbine deployment.

Click here for the full ASX Release

This article includes content from Ionic Rare Earths, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

IXR:AU

The Conversation (0)

14 September 2023

Ionic Rare Earths

Low Capital Operations With the Potential for High Margins

Low Capital Operations With the Potential for High Margins Keep Reading...

Latest News

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00