NOT FOR DISSEMINATION IN THE UNITED STATES OF AMERICA OR TO US WIRE SERVICES

- EVMET22-01 intersects 48.60 metres grading 1.31% Ni, including 13.0 metres grading 2.98% Ni

- EVMET22-02 intersects to 33.0 metres grading 0.74% Ni, including 9.0 metres grading 1.47% Ni

- Holes EVMET22-01 and EVMET22-02 submitted for Metallurgical Test Program with SGS Canada Inc.

- Metallurgical Results from Langmuir W4 anticipated by mid-summer

EV Nickel Inc. (TSXV:EVNI) ("EVNi" or the "Company") is pleased to report the assay results for three holes completed as part of the Phase 2 Drill Program, from within the Langmuir W4 Zone. The holes were designed to provide a representative sample for metallurgical analysis. Each of the three holes intersected high-grade nickel sulphide mineralization consistent with the Langmuir W4 Zone. Two of the three holes, EVMET22-01 and EVMET22-02, will be submitted for the metallurgical analysis to SGS Canada Inc., providing a suitable quantity and quality of material for their test work

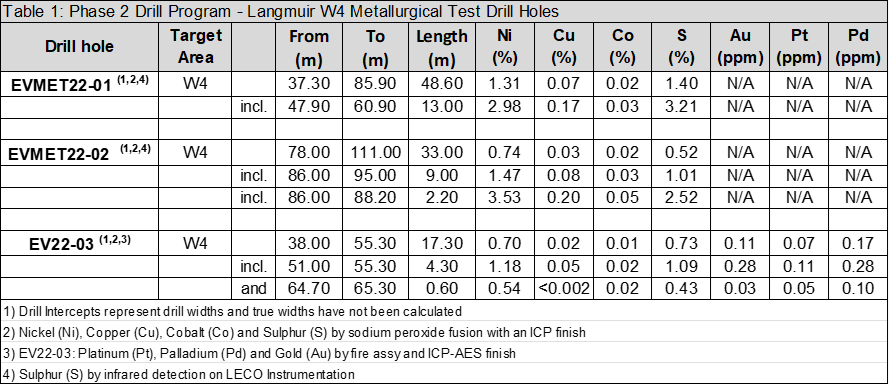

Drilling of the Langmuir W4 Zone continues to yield impressive intercepts of high-grade nickel. Hole EVMET22-01 intersected 48.6 metres grading 1.31 Ni%, including 13.0 metres grading 2.98% Ni; Hole EVMET22-02 intersected 33.0 metres grading 0.74% Ni, including 9.0 metres grading 1.47% Ni; and EV22-03 intersected 17.3 metres grading 0.70% Ni, including 4.3 metres grading 1.18% Ni. Table 1, below, summarizes the assay results for the metallurgical drill hole program.

"W4 continues to impress me with its high-grade nickel mineralization. The mineralization at W4 is unique, composed primarily of pentlandite, which relates to high nickel tenors as reflected in these high-grade nickel intercepts." states Paul Davis, EVNi's Vice President of Exploration. "The current metallurgical test program will determine the best recovery method to be used, utilizing the current mill flowsheets for facilities within a 300 km radius of the project. I am excited to see the results of the SGS metallurgical work as well as the results of our continued Phase 2 Drill Program testing the down plunge extension of the W4 zone."

The results of the Phase 2 Drill Program- Langmuir W4 Metallurgical Holes are included in Table 1:

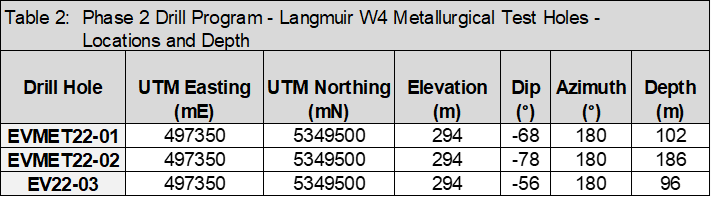

Detailed location and depth details of all Phase 2 Drill Program - Langmuir W4 Metallurgical Holes are in Table 2:

Metallurgical Testing

The Metallurgical Test program being completed by SGS Canada Inc. has the specific goals of characterizing the samples for mineralogy and grindability and the application to existing processing mill flowsheets to determine the floatation characteristics for potential recoveries and concentrate quality. Composite samples representative of the W4 mineralization will be generated from holes EVMET22-01 and EVMET22-02 for this test work. Results of the metallurgical testing are anticipated by mid-summer.

Ongoing Phase 2 Drill Program

The remainder of the Phase 2 Drill Program is testing the down plunge potential of the Langmuir W4 Zone targeting the extension of the currently defined mineralized envelope with an objective of identifying additional down plunge, high-grade nickel mineralization.

Assay QA/QC

Whole drill core samples from hole EVMET22-01 and EVMET22-02 were bagged at the core logging facility located near the property and transported to SGS Canada Inc. for preparation and analysis. Certified standards and blanks that are included by SGS for quality assurance and quality control at the laboratory. Samples are crushed and pulverized in preparation for analysis. Nickel, copper and cobalt are analyzed by sodium peroxide fusion with an ICP finish and sulphur is analyzed by infrared detection on LECO instrumentation. These and future assay results may vary from time to time due to re‒analysis for quality assurance and quality control.

Drill core samples from hole EV22-03 were cut and bagged at the core logging facility located near the property and transported to ALS Canada Ltd for analysis. Samples, along with certified standards and blanks that are included by the Company for quality assurance and quality control, were prepared and analyzed at the laboratory. Samples are crushed to 70% less than 2mm. A riffle split is pulverized to 85% passing 75 microns. Nickel, copper, cobalt and sulphur are analyzed by sodium peroxide fusion with an ICP finish and platinum, palladium and gold by fire assay and ICP-AES finish. These and future assay results may vary from time to time due to re‒analysis for quality assurance and quality control.

About EV Nickel Inc.

EV Nickel's mission is to accelerate the transition to clean energy. It is a Canadian nickel exploration company, focussed on the Shaw Dome area, south of Timmins, Ontario. In addition to extensive historic production, the Shaw Dome area is home to the Langmuir W4 Zone, the basis of a 2010 historical estimate of 677K tonnes @ 1.00% Ni, ~15M lbs of Class 1 Nickel. EV Nickel plans to grow and advance a Clean Nickel TM business, targeting the growing demand for Class 1 Nickel from the electric vehicle battery sector. EV Nickel has more than 30,000 hectares to explore and has identified more than 100km of favourable strike length.

Qualified Person

The Company's Projects are under the direct technical supervision of Paul Davis, P.Geo., and Vice-President of the Company. Mr. Davis is a Qualified Person as defined by NI 43-101. He has reviewed and approved the technical information in this press release. There are no known factors that could materially affect the reliability of the information verified by Mr. Davis.

Cautionary Note Regarding the Langmuir project's 2010 historical estimate:

Historical mineral resources for Langmuir were estimated by SRK Consulting (Canada) Inc., as documented in a report entitled, "Golden Chalice Resources Inc., Mineral Resource Evaluation, Langmuir W4 Project, Ontario, Canada", dated June 28, 2010 (the "Historical Report"). A qualified person, as defined by NI 43-101, has not done sufficient work to verify the historical assay results and technical information reported herein. The Company is not treating the Historical Report as current. The reader is cautioned not to rely upon any of the Historical Report, or the estimates therein. The historical estimates are presented herein as geological information only, as a guide to follow-up technical work, and for targeting of confirmation and exploration drilling.

Cautionary Note Regarding Forward-Looking Statements:

This press release contains forward-looking information. Such forward-looking statements or information are provided for the purpose of providing information about management's current expectations and plans relating to the future. Readers are cautioned that reliance on such information may not be appropriate for other purposes. Any such forward-looking information may be identified by words such as "proposed", "expects", "intends", "may", "will", and similar expressions. Forward-looking statements or information are based on a number of factors and assumptions which have been used to develop such statements and information, but which may prove to be incorrect. Although EV Nickel believes that the expectations reflected in such forward-looking statements or information are reasonable, undue reliance should not be placed on forward-looking statements because the Company can give no assurance that such expectations will prove to be correct. Factors that could cause actual results to differ materially from those described in such forward-looking information include, but are not limited to, changes in business plans and strategies, market conditions, share price, best use of available cash, the ability of the Company to raise sufficient capital to fund its obligations under various contractual arrangements, to maintain its mineral tenures and concessions in good standing, and to explore and develop its projects and for general working capital purposes, changes in economic conditions or financial markets, the inherent hazards associated with mineral exploration, future prices of metals and other commodities, environmental challenges and risks, the Company's ability to obtain the necessary permits and consents required to explore, drill and develop its projects and if obtained, to obtain such permits and consents in a timely fashion relative to the Company's plans and business objectives, changes in environmental and other laws or regulations that could have an impact on the Company's operations, compliance with such laws and regulations, the Company's ability to obtain required shareholder or regulatory approvals, dependence on key management personnel, natural disasters and global pandemics, including COVID-19 and general competition in the mining industry. These risks, as well as others, could cause actual results and events to vary significantly. The forward-looking information in this press release reflects the current expectations, assumptions and/or beliefs of EV Nickel based on information currently available to the Company. Any forward-looking information speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking information, whether as a result of new information, future events or results or expressly qualified by this cautionary statement.

Contact Information

For further information, visit www.evnickel.com

Or contact: Sean Samson, Chief Executive Officer at samson@evnickel.com.

EV Nickel Inc.

200 - 150 King St. W,

Toronto, ON M5H 1J9

www.evnickel.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy of this release.

SOURCE: EV Nickel Inc.

View source version on accesswire.com:

https://www.accesswire.com/704440/EV-Nickel-Phase-2-Drilling-Results-486-metres-Grading-131-Nickel-from-W4-Samples-Submitted-for-Met-Testing