- WORLD EDITIONAustraliaNorth AmericaWorld

February 19, 2023

Caravel Minerals Limited (ASX:CVV) is pleased to announce The Caravel Copper Project Pre-Feasibility Study (PFS) Update – Single Train Option Study (see ASX Announcement 20 September 2022) outlined the adoption of a single train design using High Pressure Grinding Rolls (HPGRs) in the processing plant’s primary grinding circuit, replacing Semi-Autogenous Grinding (SAG) mills originally selected in the PFS released on 12 July 2022. Further testwork has now been completed, better defining the assumptions used for the HPGR performance and specifications.

HIGHLIGHTS

- High Pressure Grinding Roll (HPGR) tests confirm Pre-feasibility Study design assumptions, including required crusher performance, reduced energy usage and higher throughput rates

- Results confirm commercial scale assumptions supporting a 27Mtpa Project with potential for future upside capacity

- Further studies will explore operating strategies to optimise power consumption and pricing

A two (2) tonne bulk sample from the Bindi East and Hinge Zone starter pits was sent for HPGR testing at the Bureau Veritas Mineral Laboratory in Perth, Western Australia. The work was conducted using an Enduron® test unit with a roll diameter of 0.80m and 0.25m wide. A total of six (6) tests were performed to determine grinding performance, energy use, wear rates, and design parameters for commercial scale application.

The tests achieved the expected size reduction from ~30mm to ~8mm, under an operating pressure of 3N/mm2 while consuming 1.6 kWh/t and operating at a nominal throughput rate of 265t/hr-m3. The positive results confirm the PFS assumptions which are typical for copper ores and confirm HPGR’s can achieve Caravel’s processing plant throughput of 27mtpa..

Two HPGRs will be incorporated into the overall crushing and grinding circuit, consisting of a primary gyratory crusher, secondary cone crushers, HPGRs and ball mills. The project is evaluating the merits of selecting industry proven HPGRs sized at 2.4m diameter, each with 8MW drives.

Additional tests are underway to optimise the energy usage across the HPGR crushing ball mill grinding circuit. Power management is an increasingly important opportunity for grid connected facilities that seek to maximise their utilisation of renewable energy and reduce exposure to short duration price peaks.

This announcement is authorised for release by Managing Director Don Hyma.

About High Pressure Grinding Rolls (HPGR’s)

HPGR units originated from the cement sector and were introduced in the mid-1980s for use in the diamond and iron ore sectors. They are now widely used in the general metalliferous industry. The copper and gold sector has increasingly used HPGRs to process harder and more abrasive ores. With more applications of the technology and ongoing development, operability and reliability has improved with industry benchmarks demonstrating operating availability of more than 90%.

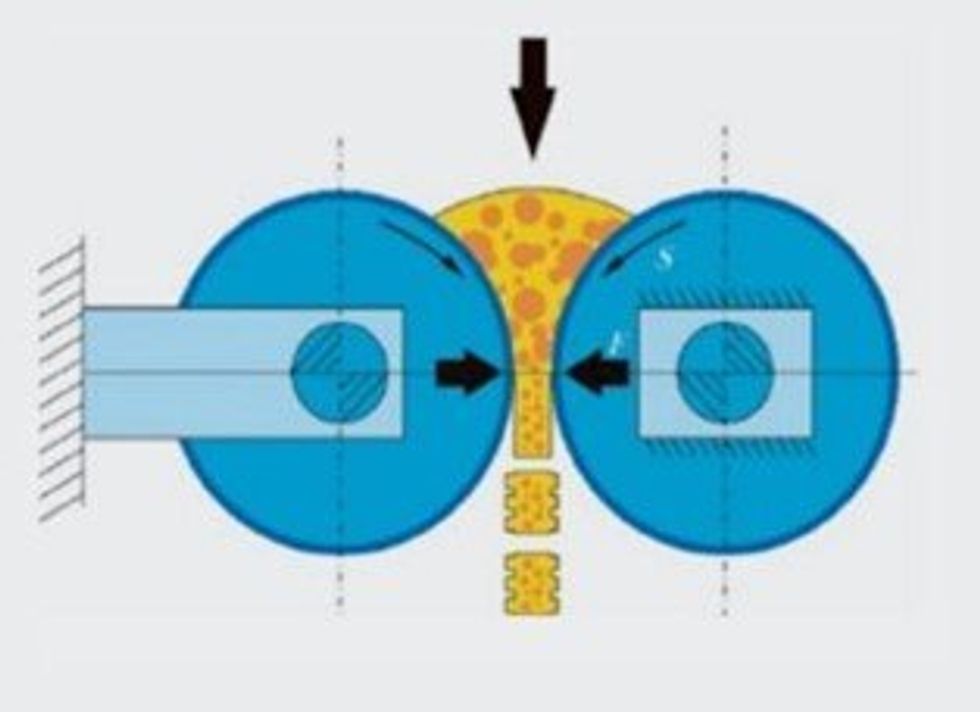

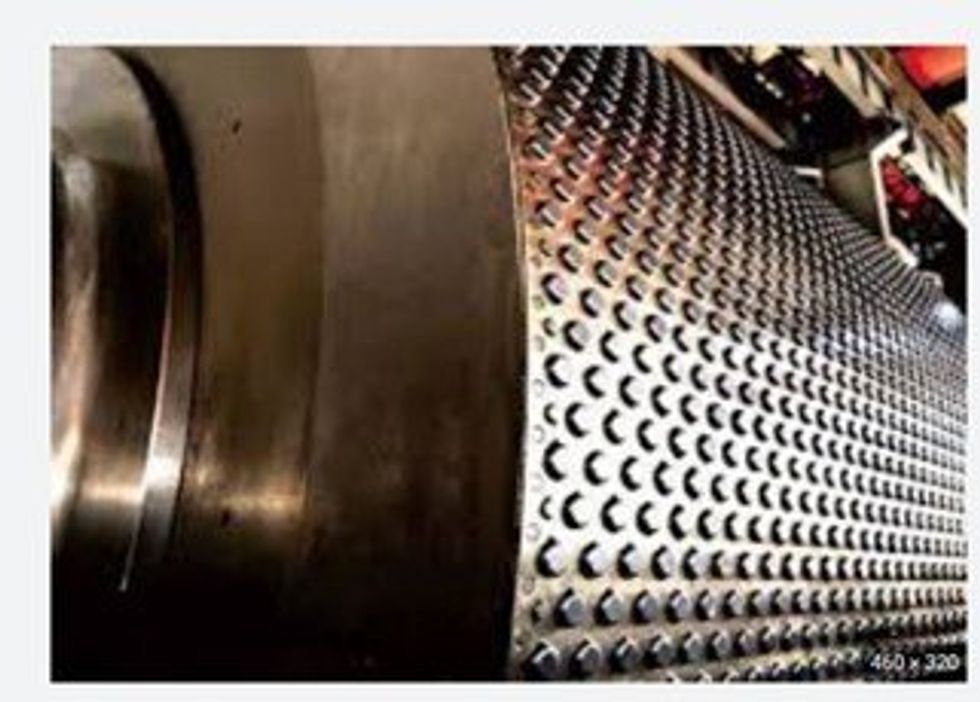

Unlike conventional roll crushing, HPGR achieves a size reduction through inter-particle compression rather than crushing of particles between the roll surfaces. Abrasion on the roll surface is managed by replaceable studs composed of highly abrasion resistant alloys. These studs are the only consumables for operation of the HPGR and can be rapidly replaced when necessary. This results in minimal downtime for maintenance and allows HPGR’s to operate with very high reliability.

Click here for the full ASX Release

This article includes content from Caravel Minerals Limited, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

The Conversation (0)

Latest News

Interactive Chart

Latest Press Releases

Related News

TOP STOCKS

American Battery4.030.24

Aion Therapeutic0.10-0.01

Cybin Corp2.140.00